Semi Mobile Primary Crushing Equipment Coal Russian

Mining SystemsEquipment TAKRAF TAKRAF GmbH

Mining Systems and Equipment TAKRAF is recognized as one of the world's leading technology brands providing specialized mining systems and equipment.Owners and

Mobile crushers Metso Outotec

Metso Outotec’s mobile crushing equipment consists of two different product families, Lokotrack® mobile crushers and Nordtrack™ mobile crushers. Both families can be

进一步探索

Lokotrack® LT106™ mobile jaw crusher Metso OutotecMobile crushers and screens — SRP根据热度为您推荐•反馈

Mobile crushers and screens — SRP

mobile crushers and screens We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection

HHI-TRSM Mining Machinery

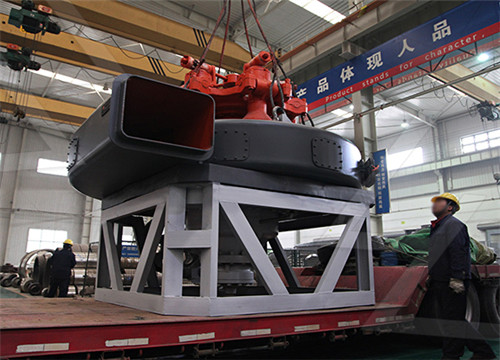

In Northeast China, Yimin open pit mine has built a new coal production system, achieving an annual increase by 5 million tons. The primary and semi-mobile crushing station

Organization of recycling of construction scrap with the

2020年3月31日[12] X Y W an d X G Yu 2013 ?The Reformation Design of the Qidashan Semi-Mobile Crusher Station?, Applied Mechanics and Materials 397-400 924-7 [13] G

Crushing plant for coal mining in Russia,Mobile coal

mpl provides complete series of coal mining equipment in Russia, including extraction plant, crusher machine, vibrating screen, belt conveyor, washing plant, preparation

Mobile Crushing Plant And Screening Plant Large

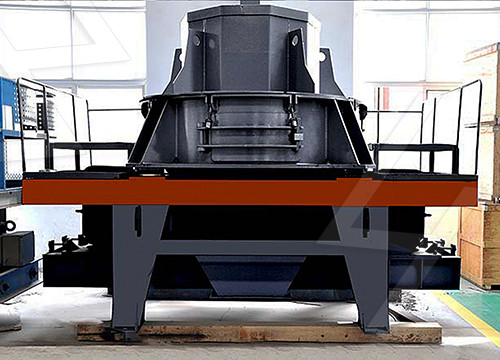

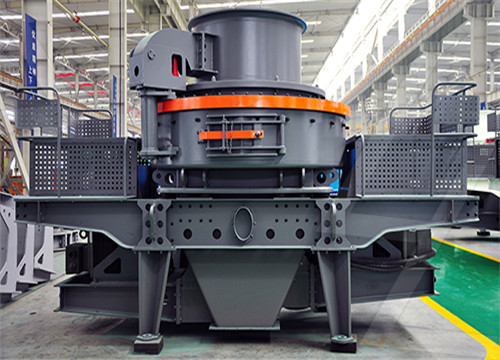

APY2-200C mobile cone crusher plant Capacity: 120-420 (t/h) Crusher model: APC-200C Maximum feed size (mm): 215 Vibrating screen model: APS-2160Y tire configuration:

Crushing Solutions Crushing Equipment Pilot Crushtec

The semi-mobile / modular solutions are comprised of standard, heavy-duty crushers supplied complete and ready to run. Crushers, mounted on skid-frames, do not require

Mobile Crushers Mineral ProcessingMetallurgy

2015年12月23日Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher. A movable crusher is positioned in the mine’s

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

Mobile crushers and screens Go to product category Breakers, demolition tools and booms Go to product category A world leader in rock processing solutions for the mining and construction industries Our constantly evolving offering for mining and construction covers crushing, screening, breaking, demolition and service solutions.

Semi-mobile primary gyratory (SMPG) Metso Outotec

Metso Outotec's Foresight™ Semi mobile primary gyratory (SMPG) crushing stations are modular by design and can be configured based on operational needs and productivity goals. There are 6 key configuration pillars that predominately will make up the configuration: Capacity is determined by hourly throughput and truck sizes

MMD Group of Companies Sizers

Sizer technology is the latest innovation in the crushing industry providing a compact and efficient way of comminution, both in underground and open pit operations. Currently MMD process over 80 different materials in more

In-Pit Crushing and Conveying (IPCC) TAKRAF GmbH

IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders

TAKRAF Mining Technology

Surface Mining and Bulk Handling Equipment. Tenova TAKRAF’s main products are mobile crushing plants, semi mobile crushing plants, bucket wheel excavators, surface miners, mobile transfer conveyors, stackers

MMD Mining Technology

Mining Machinery Developments (MMD) is a world leader in the design and manufacture of material processing equipment, in particular sizing (crushing) and feeding equipment. For over 40 years, MMD has

Organization of recycling of construction scrap with the use of mobile

2020年3月31日[12] X Y W an d X G Yu 2013 ?The Reformation Design of the Qidashan Semi-Mobile Crusher Station?, Applied Mechanics and Materials 397-400 924-7 [13] G W Cha, W H Hong, S W Shin 2013 ?A Study on

Mobile crushers Metso Outotec

Metso Outotec’s mobile crushing equipment consists of two different product families, Lokotrack® mobile crushers and Nordtrack™ mobile crushers. Both families can be utilized in aggregates production in quarries and construction sites, recycling applications, as well as in mining operations.

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

2000-12000t/h Double Roller Semi-mobile Crushing Station

Double-roller crushing station is applicable to primary crushing of gross coal or striping material in large open-pit mine with output above ten million tons and is suitable for the technology of single bucket excavator-transporting

Crushing Systems and Equipment L&T Construction

400-800 TPH semi-mobile single or double stage coal crushing cater to miningpower plant application for (-) 100 mm or (-) 20 mm sizing as required. 200-500 TPH customized skid plants for Aggregate ,Limestone and Gypsum Crushing. 200 TPH fully mobile track mounted Crusher.

en/spesifikasi primary crusher pdf coal russian.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Leading copper producer relies on FLS crushing plants

2023年1月20日Back 20 January 2023 has been selected to supply the 9th high performance semi-mobile crushing plant in a row to a leading copper miner in the world. This new crushing plant will increase production and efficiency, contributing to the customer's expansion plans in Africa.

Metso Outotec aims for higher capacities as ore sorting offering

2022年8月30日With crushing stations at least in the in-pit crushing and conveying (IPCC) space that can go up to 15,000 t/h (see the company’s Foresight™ semi-mobile primary gyratory station), the prospect of Metso Outotec making a concerted effort to get into the bulk ore sorting space bodes well for the rising throughputs of projects.

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

Mobile crushers and screens Go to product category Breakers, demolition tools and booms Go to product category A world leader in rock processing solutions for the mining and construction industries Our constantly evolving offering for mining and construction covers crushing, screening, breaking, demolition and service solutions.

Semi-mobile primary gyratory (SMPG) Metso Outotec

Metso Outotec's Foresight™ Semi mobile primary gyratory (SMPG) crushing stations are modular by design and can be configured based on operational needs and productivity goals. There are 6 key configuration pillars that predominately will make up the configuration: Capacity is determined by hourly throughput and truck sizes

In-Pit Crushing and Conveying (IPCC) TAKRAF GmbH

IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders

TAKRAF Mining Technology

Ship loader, for Port of Ust-Luga, Russia Capacity: 3500 t/hrMaterial: Coal. Semi-mobile crushing plant at Old Cliffe Hill Quarry/Great BritainCapacity: 2,500t/hr. Material: Granite rock. Stacker/reclaimer for Vitoria Stockyard,

Organization of recycling of construction scrap with the use of mobile

2020年3月31日[12] X Y W an d X G Yu 2013 ?The Reformation Design of the Qidashan Semi-Mobile Crusher Station?, Applied Mechanics and Materials 397-400 924-7 [13] G W Cha, W H Hong, S W Shin 2013 ?A Study on

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Crushing Systems and Equipment L&T Construction

400-800 TPH semi-mobile single or double stage coal crushing cater to miningpower plant application for (-) 100 mm or (-) 20 mm sizing as required. 200-500 TPH customized skid plants for Aggregate ,Limestone and Gypsum Crushing. 200 TPH fully mobile track mounted Crusher.

PX100 Bulk Materials Handling Equipment Semi-mobile

Essential part of In-pit Crushing and Conveying (IPCC) Turn-key projects for customized semi-mobile crushing plants in various applications with high capacities; Superior crushing technology with primary gyratory crusher; Cost efficient, no apron feeder is required; To be shifted by transport crawlers to different locations within the mine

thyssenkrupp wins semi-mobile-crushing-plant

2020年6月26日Posted by Daniel Gleeson on 26th June 2020. thyssenkrupp has been awarded a contract to supply three semi-mobile-crushing-plants (SMCP) to a major open-pit coal mine in the Singrauli

en/spesifikasi primary crusher pdf coal russian.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

2000-12000t/h Double Roller Semi-mobile Crushing Station

Double-roller crushing station is applicable to primary crushing of gross coal or striping material in large open-pit mine with output above ten million tons and is suitable for the technology of single bucket excavator-transporting

Metso Outotec aims for higher capacities as ore sorting offering

2022年8月30日With crushing stations at least in the in-pit crushing and conveying (IPCC) space that can go up to 15,000 t/h (see the company’s Foresight™ semi-mobile primary gyratory station), the prospect of Metso Outotec making a concerted effort to get into the bulk ore sorting space bodes well for the rising throughputs of projects.

Fixed and Semi-mobile Primary Gyratory Stations

Semi-mobile primary gyratory stations Semi-mobile solutions for in-pit crushing Metso capitalizes on decades of experience in the design and manufacturing of crushers and complete systems. We offer you an in-pit crushing solution with the goal of increasing productivity and profitability.

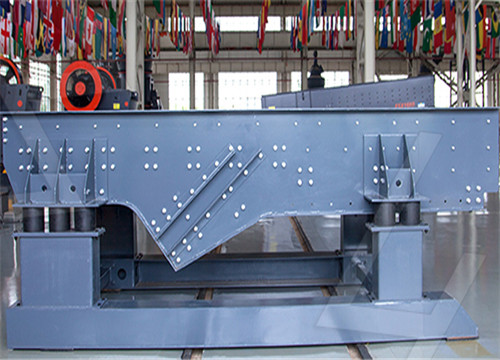

Mobile Feeder and Hopper Industrial Hopper Feeders Pilot

The Metso Modular feed and hopper range consists of a complete range of ready to use semi-mobile, skid mounted grizzly and vibrating feed hoppers, designed for rapid installation and ideal for removing oversize rock and ore from feed material before the primary crushing process. Our modular range is versatile and in-stock; ready for your

- 破碎锤多少小时换新液压油

- 边齿版\FP50AM

- 干式制砂可行性分析报告

- 仿瓷墙体起泡是什么原因

- Cone Crushers Manufacturer Wearing Parts Primary Crusher Malaysia Steel

- 什么地方用碎沙机

- Best Beneficiation Equipment For Long Stone Jambi?Indonesia

- Screening Rail Shoulder Ballast

- 云母水力旋流器

- 绿色环保餐盒生产线

- 冲击破路机

- 石骨料破碎机是液压

- Adamson Lehi Roller Mills

- 湖南湘潭褐铁鄂式破碎设备

- 砂石料计量控制