Cone Crushers Manufacturer Wearing Parts Primary Crusher Malaysia Steel

Crusher Wear Parts Amsted Global Solutions

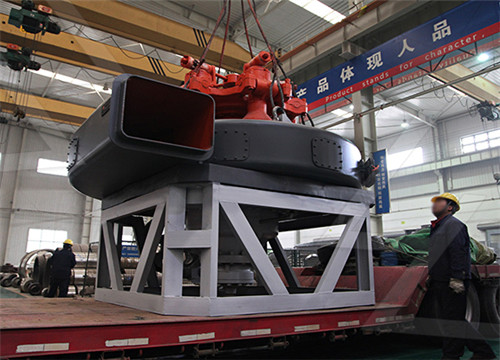

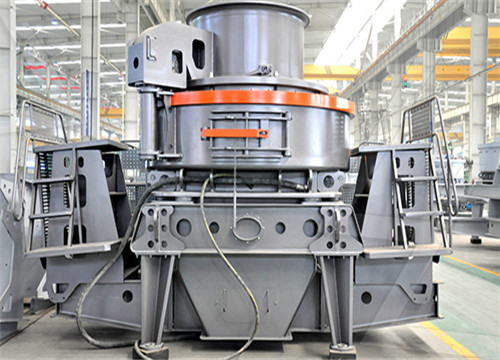

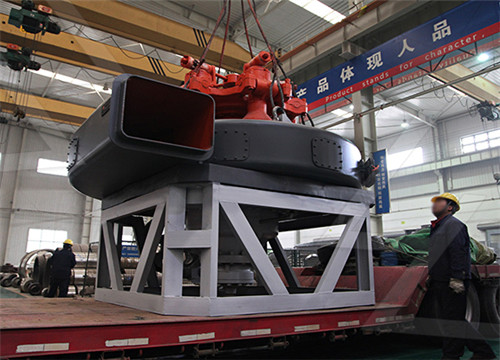

A cone crusher is a machine that reduces material size by compressing the feed material between a moving piece of steel and a stationary piece of steel. Mining and aggregate

Crushing Metso Outotec

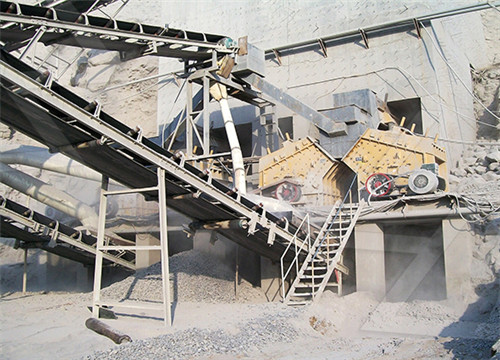

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso Outotec equipment is manufactured to meet your material

进一步探索

All Metso Corporation catalogs and technical brochures DirCrushing and Screening Handbook Metso Outotec根据热度为您推荐•反馈

Cone crusher parts Wear Parts For Industry Qiming Casting

A cone crusher is a type of rock-crushing equipment used in mining and aggregate industries. It is designed to crush a variety of materials such as hard and medium-hard

Cone Crusher Replacement Wear Parts Columbia Steel

Cone Crusher Parts Columbia Steel is a leading manufacturer of cone crusher wear parts with more design options than any other manufacturer in the world. heavy-duty,

Crusher Wear Parts for Popular Crushers Columbia Steel

of improved crusher replacement part designs. from a single manufacturer, anywhere. Our product engineers are problem-solving specialists, designing crushing surfaces to handle

Kue-Ken CT Cone Crusher SparesReplacements CMS

CMS Cepcor® is now the primary aftermarket supplier of crusher spare parts and crusher wear parts to suit Kue-Ken cone crushers (Brown Lenox). Manganese steel wear

Primary Crusher Components Crusher Mills, Cone Crusher, Jaw

Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher . The crushers components are of high strength design to accept high power draw. . Jaw Crusher is

Cone Crusher Explained saVRee

The cone crusher was first developed in United States in the 1920’s by Symons Brothers of Milwaukee. Symon Brothers are credited as the first designers and inventors of the

Crusher Wear Parts Casteel Foundry

Crusher Wear Parts. High Manganese jaw plate ,side plates,Jaw Wedges,Hardox cheek plates,Carbon Steel Toggle Plate and machining Toggle seat . Mantle, Concave rings

Laboratory and pilot plant Primary Jaw Crushers

EXCEL™ cone crusher parts for Omnicone® Cone Crushers; The jaw plates are made from hard-wearing BISALLOY ® Wear steel, The heavy-duty, general purpose Essa JC3000 Jaw Crusher is a well proven, highly productive primary crusher used in sample preparation and plant applications. More powerful than the JC2000, it is suitable for

Crushing Metso Outotec

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso Outotec equipment is manufactured to meet your material reduction requirements. The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and

Crusher wear parts Metso Outotec

Max Series crusher wear parts When crusher uptime and efficiency are critical When every percent makes a difference, you need expertise on many levels. With the holistic approach of the Max Series, we optimize each step of your process with custom parts to maximize your performance, economy, and sustainability.

Compression mining crushers Primary crushers

Compression mining crushers solutions for breaking down hard minerals and ores Enjoy optimum performance and reduced cost with compression crusher equipment and products. For over a century, has been renowned as the preferred crushing technology provider for mining and related industries. Stay updated on your industry

Industrial CastingsWear Parts Columbia Steel

Wear parts for the world’s toughest industries. longer wear life, and lower rigging weight. Read More. Ore and Aggregate Crushers. A broad range of crusher wear part designs for gyratory, cone, and jaw crushers. Read More. Crusher Wear Studies. When you’re ready to improve your crusher performance, get the facts first — get a wear

Crusher Wear Parts for Popular Crushers Columbia Steel

of improved crusher replacement part designs. from a single manufacturer, anywhere. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Kue-Ken CT Cone Crusher SparesReplacements CMS Cepcor Ltd

CMS Cepcor® is now the primary aftermarket supplier of crusher spare parts and crusher wear parts to suit Kue-Ken cone crushers (Brown Lenox). Manganese steel wear parts. CMS Cepcor® stocks a range of concaves, mantles, mantle retainers, mantle nuts and distributor plates to suit the CT range of cone crushers. Crusher parts Made in GB

Crusher Wear Parts For Jaw, Cone, Impact, VSI, and Gyratory Crusher

Crusher Wear Parts By Qiming Machinery®. Qiming Machinery is a leader crusher wear parts foundry in China, which manufactures jaw, cone, impact, VSI, and gyratory crusher wear parts for all popular brands. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material

Cone crusher, Cone crushing and screening plant All industrial

Cone Crusher Cone crushers are the crusher of the FTC-300 crawler 60-80 tph Maximum Feeding Size: 550 x 300 mm Feeding Height: 3.8 meters Main Configuration: Primary Jaw Crusher Compare this product Remove from Cone Crusher HP200 Crusher Wear Parts from China Manufacturer Manganese steel liner Suit for

WEAR SOLUTIONS H-E Parts

H-E Parts designs and manufactures gyratory concaves in manganese steel and liquid quenched Ni-Cr-Mo steels that have been proven to provide longer, more consistent life than most common air-quenched concaves, with far less risk of failure that can be encountered with white irons.

Crusher Liners World-Leading Crusher Liners CMS Cepcor

The crusher liners by CMS Cepcor® often exceed the performance of the original manufacturer parts. Contact us today to find out about our range of liners. +44 (0) 1530 817000

Crusher wear parts ᐈ Order accessories for crushers Mining

Crusher linings. Mining Element produces linings for the cone, bowl, arm, driveshaft, the frame, as well as distribution plates. Components for crushers from Mining Element have guaranteed compatibility with any type of crushing equipment. They are all made of high-quality materials and the customer keeps full control of the production cycle.

Crusher Wear Parts Columbia Steel Australia

2019年1月8日Columbia Steel’s product engineers are experts in designing crusher wear parts to increase production throughout the life of the part, and to increase overall wear life. We regularly improve crushing surfaces to handle oversize material, break slabbly material, and reduce recirculation, resulting in better overall plant performance.

Laboratory and pilot plant Primary Jaw Crushers

EXCEL™ cone crusher parts for Omnicone® Cone Crushers; The jaw plates are made from hard-wearing BISALLOY ® Wear steel, The heavy-duty, general purpose Essa JC3000 Jaw Crusher is a well proven, highly productive primary crusher used in sample preparation and plant applications. More powerful than the JC2000, it is suitable for

Crushing Metso Outotec

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso Outotec equipment is manufactured to meet your material reduction requirements. The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and

Industrial CastingsWear Parts Columbia Steel

Wear parts for the world’s toughest industries. longer wear life, and lower rigging weight. Read More. Ore and Aggregate Crushers. A broad range of crusher wear part designs for gyratory, cone, and jaw crushers. Read More. Crusher Wear Studies. When you’re ready to improve your crusher performance, get the facts first — get a wear

Crusher Wear Parts for Popular Crushers Columbia Steel

Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter, resulting in better overall plant performance.

Cone crusher parts Wear Parts For Industry Qiming Casting

A cone crusher is a type of rock-crushing equipment used in mining and aggregate industries. It is designed to crush a variety of materials such as hard and medium-hard rocks, ores, and minerals. Cone crushers are commonly used in the secondary, tertiary, and quaternary stages of crushing. They work by compressing the material between a

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Applications Aggregates Coal Concrete Crushing Frac Sand Mining Jump To: How Cone Crushers Work Resources Why McLanahan FAQs FeaturesBenefits

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日Cone Crusher MANTLE. The Mantalloy head mantle of this cone crusher is a replaceable wearing surface. It is made of alloyed manganese steel, and is held in place with a self-tightening head nut. On the 51-in. Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion

Kue-Ken CT Cone Crusher SparesReplacements CMS Cepcor Ltd

CMS Cepcor® is now the primary aftermarket supplier of crusher spare parts and crusher wear parts to suit Kue-Ken cone crushers (Brown Lenox). Manganese steel wear parts. CMS Cepcor® stocks a range of concaves, mantles, mantle retainers, mantle nuts and distributor plates to suit the CT range of cone crushers. Crusher parts Made in GB

Cone Crusher Liners: How to Select and When to Change

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

Crusher Wear Parts For Jaw, Cone, Impact, VSI, and Gyratory Crusher

Our cone crusher wear parts are produced at our own foundry and manufacturing facilities. As a result, we have complete control over quality at every step of the process, from the selection of raw materials to final production. Common cone wear parts include: Mantles Bowl liners Concaves Feed cones View More HSI Crusher Wear Parts

Cone crusher, Cone crushing and screening plant All industrial

Cone Crusher Cone crushers are the crusher of the FTC-300 crawler 60-80 tph Maximum Feeding Size: 550 x 300 mm Feeding Height: 3.8 meters Main Configuration: Primary Jaw Crusher Compare this product Remove from Cone Crusher HP200 Crusher Wear Parts from China Manufacturer Manganese steel liner Suit for

WEAR SOLUTIONS H-E Parts

H-E Parts designs and manufactures gyratory concaves in manganese steel and liquid quenched Ni-Cr-Mo steels that have been proven to provide longer, more consistent life than most common air-quenched concaves, with far less risk of failure that can be encountered with white irons.

Crusher Liners World-Leading Crusher Liners CMS Cepcor

The crusher liners by CMS Cepcor® often exceed the performance of the original manufacturer parts. Contact us today to find out about our range of liners. +44 (0) 1530 817000

Primary Impact Crushers MEKA CrushingScreening Plants

MEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration. This helps the crusher to operate safely and boosts productivity. MEKA primary impact crushers are equipped with a hydraulic lifter, which allows the user to open the crusher’s Upper body

- 石灰石矿山开采专用钻机

- Belt Conveyer For Dolomite Bandar?Lampung?

- 尿素水生产设备多少钱

- 国外常用粉末冶金材料牌号对照表

- 花岗岩石头多少钱

- 德国 破碎机 800目

- 锅炉脱硫工艺流程

- Tanaman Khas Untuk Tambang Uranium

- Chiles Largest Rock Crushing Equipment

- 石料研磨机械工作原理

- Surface Crusher Machine Joen Lih

- Pef Copper Ball Mill Ball Mill Pe With Casting Tec

- Portable Wash Up Sinks In Cape Town

- 万吨立磨价格年产

- Seafight Dot Web Mining Mill 2 5 Keygen