Screening Rail Shoulder Ballast

Shoulder Ballast Cleaning Loram

The benefits of shoulder ballast cleaning include: Improved drainage that extends surfacing and undercutting cycles and reduces tamping needs up to 200% Enhanced lateral

进一步探索

Ballast maintenance update: Better, faster ballastMaintenance of way: Ballast maintenance practices ProBallast Maintenance, Delivered Railway AgeBallast Management Equipment Update 2019What is Ballasting And De-ballasting ? MethodsProc根据热度为您推荐•反馈

Impact of Shoulder Cleaning on Ballast Drainage FRA

2022年11月22日Shoulder Cleaning on Ballast Drainage.pdf (582.56 KB) The Federal Railroad Administration (FRA) and the Association of American Railroads (AAR) jointly

IMPACT OF SHOULDER CLEANING ON BALLAST

Testing (FAST) in Pueblo, CO. The test section is 20 feet long and has a Selig’s Fouling Index (FI) of 40, indicating most of the ballast voids are filled with fines. In addition, the

The contribution of base, crib and shoulder ballast to

Shoulder ballast The resistance to movement at the sleeper end might be estimated by considering the limiting equilibrium of a three-dimensional wedge of ballast, bounded by

Ballast Maintenance Railway Track and Structures

2013年8月5日Balfour Beatty Rail’s new ZRL200 20D high-speed LIDAR scanning system produces surface profiles of the ballast. This can be compared with customers’ trackbed

Maintaining ballast Railway Track and Structures

2014年3月19日Balfour Beatty Rail’s ZRL200 20D high-speed LIDAR scanning system produces surface profiles of the ballast, which can be compared with customers’

Track ballast Wikipedia

The ballast shoulder should be at least 150 mm (6 inches) wide, and may be as wide as 450 mm (18 inches). [9] Ballast must be irregularly shaped to work properly The shape of the ballast is also important. Stones must be

CHAPTER 3 BALLAST CLEANING AND HANDLING

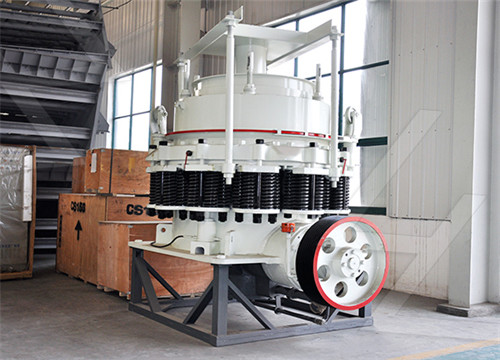

Shoulder Ballast Cleaning Machines are used for cleaning of only shoulder ballast (beyond sleeper edge) by excavating and screening of ballast and removal of muck for

Loram High Performance Shoulder Ballast Cleaner

2017年5月26日A firm foundation is paramount to proper track performance and proper drainage is key to maintaining that foundation. Trapped water in the ballast decreases

Impact of Shoulder Cleaning on Ballast Drainage FRA

2022年11月22日Testing was conducted between 2021 and 2022 at the “Rainy Section,” a degraded ballast test section at the Facility for Accelerated Service Testing (FAST) in Pueblo, CO. Research findings indicate better shoulder drainage resulting from shoulder cleaning can improve drainage capacity, reduce surface mud pumping, and reduce track

IMPACT OF SHOULDER CLEANING ON BALLAST DRAINAGE

Testing (FAST) in Pueblo, CO. The test section is 20 feet long and has a Selig’s Fouling Index (FI) of 40, indicating most of the ballast voids are filled with fines. In addition, the section uses an irrigation system to control the wetting of the ballast. Research findings indicate better shoulder drainage resulting from shoulder cleaningcan

Railroad Ballast Movements Pattern Recognition by Using

2021年8月5日This stone presents a series of ballast box tests to investigate ballast particle movement pattern inside railway ballast under different load frequency, load magnitude, moisture conditions and shoulder confinement.

Ballast Maintenance Loram

As a global leader in maintenance of way for over 50 years, Loram’s expansive equipment portfolio and highly-trained crews deliver best-in-class services with unmatched performance and safety standards. Call +1

Track ballast Wikipedia

The ballast shoulder should be at least 150 mm (6 inches) wide, and may be as wide as 450 mm (18 inches). [9] Ballast must be irregularly shaped to work properly The shape of the ballast is also important. Stones must be

Shoulder Ballast Cleaning Effectiveness Loram Maintenance

shoulder cleaning process was highly effective in removing fines and restoring desirable shoulder ballast support and drainage properties. Further periodic analysis also supports that the fines in the center of the track and along the shoulders tend to move outward and downward during the test with the percentage of fines in the cleaned

Railroad ballast maintenance equipment update Progressive

Progress Rail Services' newest shoulder ballast cleaner is the KSC2000, which features a single shaker screen design capable of cleaning 2,900 tons of ballast per hour.

METHODS OF CLEANING STONE BALLAST AREMA

Hand cleaning of ballast is done with both forks and screens. In cleaning ballast with forks, the ballast is dug out with picks and shovels and thrown upon the roadbed shoulder. If wet or damp, it is first allowed to dry and is then shaken clean with the aid of forks and cast back into the track. Another method of cleaning ballast in the

Screening rail shoulder ballast Manufacturer Of High-end

Ballast Maintenance Railway Track and Structures. Ballast cleaning and ballast reclamation is another area where Kershaw has been actively working with customers Kershaw recently delivered a new KSC2000 High Speed Shoulder Cleaner that is capable of cleaning the shoulder ballast screening and spoiling the waste and returning the

3. 1 Tie Tamping Machines Indian Railways

i) A minimum cushion of 150 mm of clean ballast is recommended for the proper functioning of the machine. Adequate ballast should be available in shoulders and cribs to allow for required lift ( about 20 mm in each tamping operation) and retention of

Numerical investigation into the effect of ballast properties on

2020年11月5日In this , the effect of ballast properties including ballast depth, shoulder width, shoulder height, inter particle friction angle and ballast porosity on track buckling capacity...

Ballast cleaner Wikipedia

A ballast cleaner (also known as an undercutter, a shoulder ballast cleaning machine) is a machine that specialises in cleaning the railway track ballast (gravel, blue stone or other aggregate) of impurities. [1]

(PDF) Developing Track Ballast Characteristic Guideline In

2016年12月31日As the main component of ballast track, ballast has a decisive influence on the stability, durability and toughness of the whole ballasted track structure. The ballast layer has the following

Impact of Shoulder Cleaning on Ballast Drainage FRA

2022年11月22日Shoulder Cleaning on Ballast Drainage.pdf (582.56 KB) The Federal Railroad Administration (FRA) and the Association of American Railroads (AAR) jointly supported Transportation Technology Center, Inc., (TTCI) to investigate the influence of shoulder ballast cleaning (SBC) on the performance of fine-filled ballast.

Shoulder Ballast Cleaning Loram

A Loram shoulder ballast cleaning program ensures a healthy, robust railroad infrastructure maintained to deliver maximum ROI. Shoulder ballast cleaning consists of removing ballast at the end of the ties, screening the ballast and discarding fines and fouling material and restoring the good ballast to the shoulder.

IMPACT OF SHOULDER CLEANING ON BALLAST DRAINAGE

Testing (FAST) in Pueblo, CO. The test section is 20 feet long and has a Selig’s Fouling Index (FI) of 40, indicating most of the ballast voids are filled with fines. In addition, the section uses an irrigation system to control the wetting of the ballast. Research findings indicate better shoulder drainage resulting from shoulder cleaningcan

(PDF) Contribution of Base, Crib, and Shoulder Ballast

2011年3月1日shoulder size within the test data reported by ERRI for “ just tamped ” track has a “ 50% less than ” lateral sliding resistance of 8.3 kN (Table 1). If the resistance of 8.3 kN is taken to

Maintaining ballast Railway Track and Structures

2014年3月19日Balfour Beatty Rail’s ZRL200 20D high-speed LIDAR scanning system produces surface profiles of the ballast, which can be compared with customers’ trackbed templates for both tangent and curved track to identify areas of noncompliance. The system also allows detailed structural clearance measurements to be obtained during routine

Ballast Maintenance Loram

Shoulder Ballast Cleaning Ditching Specialty Excavating Undercutting Loram Rail Grinding Services and Equipment Portfolio Learn How We Can Help As a global leader in maintenance of way for over 50 years,

Track ballast Wikipedia

The ballast shoulder should be at least 150 mm (6 inches) wide, and may be as wide as 450 mm (18 inches). [9] Ballast must be irregularly shaped to work properly The shape of the ballast is also important. Stones must be

Railroad ballast maintenance equipment update Progressive

Progress Rail Services' newest shoulder ballast cleaner is the KSC2000, which features a single shaker screen design capable of cleaning 2,900 tons of ballast per hour.

Screening rail shoulder ballast Manufacturer Of High-end

Ballast Maintenance Railway Track and Structures. Ballast cleaning and ballast reclamation is another area where Kershaw has been actively working with customers Kershaw recently delivered a new KSC2000 High Speed Shoulder Cleaner that is capable of cleaning the shoulder ballast screening and spoiling the waste and returning the

Ballast cleaner Wikipedia

A ballast cleaner (also known as an undercutter, a shoulder ballast cleaning machine) is a machine that specialises in cleaning the railway track ballast (gravel, blue stone or other aggregate) of impurities. [1]

(PDF) Developing Track Ballast Characteristic Guideline In

2016年12月31日As the main component of ballast track, ballast has a decisive influence on the stability, durability and toughness of the whole ballasted track structure. The ballast layer has the following

Shoulder Ballast Cleaner Work Method Statement

Shoulder Ballast Cleaner Work Method Statement This document is uncontrolled when printed Version Number: 1.0 Date Reviewed: 13 May 2016 Page 1 of 14 Shoulder Ballast Cleaner Specific to SBC34 Warning You cannot undertake this activity in the rail corridor unless you have completed a pre work brief and work site protection plan.

The Effect of Fouling Materials on Permeability SpringerLink

2021年10月25日Ballast is a well-known granular type material used in ballasted railway track which is widely used and traditional track system in most countries including Sri Lanka. The ballast layer supports dynamic stresses transmitted from faster and heavy trains and distributes safely to the underlying layers.