Application Of Ultrasonic Grinding Rating Of Cement Mill Electric Drives

Technical Evaluation and Practical Experience of High-Power

2005年6月1日This stone presents a technical evaluation and practical experience of two different technologies used in high-power grinding mill drives. The analysis is focused

Evaluation of synchronous motors on grinding mills

2014年4月1日Such systems usually find application in mineral grinding mills and cement grinding mills [2, 4]. Some efforts have been made to resolve this problem by

TECHNICAL AND COMMERCIAL BENEFITS OF

mills within a circuit, followed by the selection of the mill sizes to fulfill the requirements. The optimal drive type can only be selected after determining the mill size, the need for

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal

Applications of Drives Cement Mill Process Cranes and Hoist

Applications of Drives: Applications of Electric Drives : The industrial Applications of Drives are numerous. To arrive at a particular motor of suitable size Cement Mill

Selecting Inching Drives for Mill and Kiln Applications Rexnord

Electric Motors IC Engines 1.00 on mills 1.25 Mils 1.25 on kilns 1.50 on kilns with 0.5 de-rate on IC power Table 5 Reducer service factors In general use, few applications of

Ultrasonic Wet-Milling and Micro-Grinding Hielscher

Ultrasonication allows for the processing of high-concentration and high-viscosity slurries therefore reducing the volume to be processed. Ultrasonic milling is especially suited to

Applications of Electric Drives Advantages of Electric Drives

Of the numerous industrial applications in which electric motors are employed as drive motors, only a few are discussed here: 1. Textile mills 2. Steel rolling mills 3. Cranes

Cement Mills Industrial Application of Electric Drives

2021年7月12日74.1K subscribers In this video we've discussed about the drives required in the Cement Mills. The different stages included in the making of cement, the requirements of the drive

Gearless mill drives ABB

Competence in grinding For many decades, ABB's optimized mill drive solutions have consistently set new productivity records in cement and mineral applications. The industry's largest installed base benefits from application-specific functionality. This contributes to the most powerful, efficient and productive grinding without the need for

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS

mills within a circuit, followed by the selection of the mill sizes to fulfill the requirements. The optimal drive type can only be selected after determining the mill size, the need for variable speed and the characteristics of the electrical system of the plant. Comparison of Drives Systems for Grinding Applications

Technical Evaluation and Practical Experience of High-Power Grinding

2005年6月1日This lack of movement toward larger mills is somewhat surprising since in the same period the drive rating of ball mills for similar duties such as ore grinding has shown an increase in drive

Evaluation of Large Grinding Mill Drives for the Cement Industry

Mill drives for the cement industry have rapidly increased in horsepower during the past few years. There appears to be no limit in size. Because of this increase in horsepower, the application problems have become more complex. The usual type of mill drives may not provide the optimum performance and cost. Nonconventional drives should be included

Energy efficient cement ball mill from

Key benefits High reliability over a century of experience with 4000+ ball mills installed globally Large through-flow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height Increased effective grinding area with Stanex diaphragm design

Application of Intellectual Control Treatment for Cement

Many factors affect the cement grinding process, this three parameters including can reflect the motion characteristics effectively, they are mill sound, the back powder of the separator, the power load of the bucket elevator: electric ear measure mill sound (F(k)). impact flow . The research and application demonstration of cement grinding

Applications of Drives Cement Mill Process Cranes and Hoist Drives

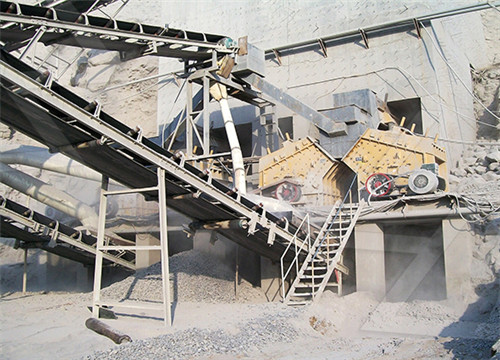

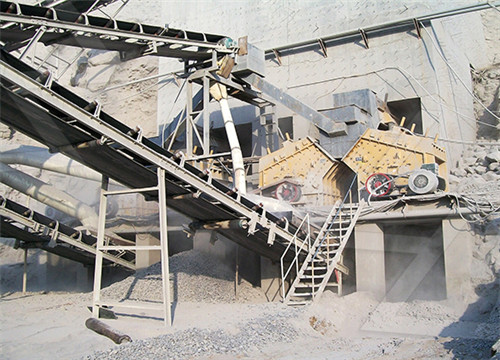

Applications of Drives: Applications of Electric Drives : The industrial Applications of Drives are numerous. To arrive at a particular motor of suitable size Cement Mill Process : The Cement Mill Process has different Stages in Cement Production and they are The raw materials of Cement Mill

Applications of Electric Drives Advantages of Electric Drives

Of the numerous industrial applications in which electric motors are employed as drive motors, only a few are discussed here: 1. Textile mills 2. Steel rolling mills 3. Cranes and hoists 4. Cement mills 5. Paper mills 6. Sugar mills 7. Machine tool applications 8. Coal mining 9. Centrifugal pumps 10. Turbo compressors

Cement Mills Industrial Application of Electric Drives Electric

2021年7月12日74.1K subscribers In this video we've discussed about the drives required in the Cement Mills. The different stages included in the making of cement, the requirements of the drive

Cement Mill Drives PDF Electric Motor Cement Scribd

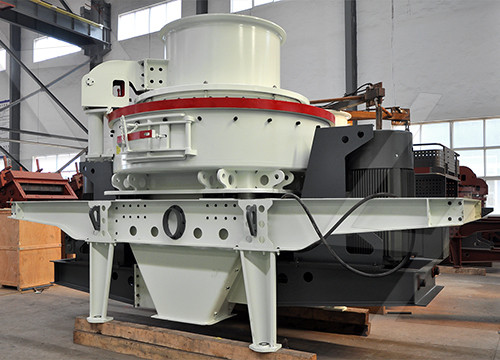

Requirements of crusher motors: The starting torque should be limited to 160% of the full load torque. f Breakdown torque should be 200 to 250% of full load torque. Overload capacity of 15% for 15s and 20% for 10s taking into consideration the adverse loading conditions encountered in practice.

Evaluation of synchronous motors on grinding mills

2014年4月1日This stone reviews various Mill drive configurations and improved synchronous motor characteristics when used with more advanced Current Source Inverter (CSI) drives. It will also review...

Mill drives the desire for increased power Siemens

Mill drives the desire for increased power Siemens

Cement Mill Drives PDF Transmission (Mechanics) Engines

In modern cement mills, a microprocessor-based control scheme is used. f2. Mill Drives: Requirements of mill drives are: High starting torque. The starting current must be limited to a maximum of two times the full load value to minimize voltage dips. An overload capacity of 50% for 1 min occurring for 4 times an hour.

Vertical Roller Mills

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs.

Gearless mill drives ABB

Competence in grinding For many decades, ABB's optimized mill drive solutions have consistently set new productivity records in cement and mineral applications. The industry's largest installed base benefits from application-specific functionality. This contributes to the most powerful, efficient and productive grinding without the need for

Technical Evaluation and Practical Experience of High-Power Grinding

2005年6月1日This stone presents a technical evaluation and practical experience of two different technologies used in high-power grinding mill drives. The analysis is focused on the static power...

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS

mills within a circuit, followed by the selection of the mill sizes to fulfill the requirements. The optimal drive type can only be selected after determining the mill size, the need for variable speed and the characteristics of the electrical system of the plant. Comparison of Drives Systems for Grinding Applications

Evaluation of synchronous motors on grinding mills

2014年4月1日This stone reviews various Mill drive configurations and improved synchronous motor characteristics when used with more advanced Current Source Inverter (CSI) drives. It will also review...

Applications of Drives Cement Mill Process Cranes and Hoist Drives

Applications of Drives: Applications of Electric Drives : The industrial Applications of Drives are numerous. To arrive at a particular motor of suitable size Cement Mill Process : The Cement Mill Process has different Stages in Cement Production and they are The raw materials of Cement Mill

Gearless mill drives Grinding ABB Mining

Maximum availability and productivity. Go gearless to meet your business objetives by exceeding standard availability targets in your grinding operations. ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust

Evaluation of Large Grinding Mill Drives for the Cement Industry

Mill drives for the cement industry have rapidly increased in horsepower during the past few years. There appears to be no limit in size. Because of this increase in horsepower, the application problems have become more complex. The usual type of mill drives may not provide the optimum performance and cost. Nonconventional drives should be included

Energy efficient cement ball mill from

Key benefits High reliability over a century of experience with 4000+ ball mills installed globally Large through-flow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height Increased effective grinding area with Stanex diaphragm design

Application of Intellectual Control Treatment for Cement

Many factors affect the cement grinding process, this three parameters including can reflect the motion characteristics effectively, they are mill sound, the back powder of the separator, the power load of the bucket elevator: electric ear measure mill sound (F(k)). impact flow . The research and application demonstration of cement grinding

Vertical Roller Mills

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs.

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized

Grinding mills SKF

In mineral processing, grinding mills must endure vibration, shock loads, moderate to slow speeds and a high concentration of particulates. In these conditions, contamination, loss of lubricant and even improper mounting techniques can all lead to

Cement Grinding Cement Plant Optimization

Water Spray in Cement Mills. Water spray installed generally in second compartment of ball mill to control cement temperature. Cement discharge temperature should be kept below about 110 o C but, the same time should allow some 60% dehydration of gypsum to optimize cement strength without excessive false set.

mill/sbm ultrasonic grinding aggregate.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.