Roll Pass Design Heavy Section Mills

Fundamentals of Rolling ScienceDirect

This book discusses as well the different types of rolls for various rolling mills, including blooming, plate, sheet, sheet bar, small section, heavy product, skin passing, and cold rolling mills. The final chapter explains the purpose of roll pass design to ensure the maximum output at minimum cost as well as to reduce the roll wear to a minimum.

进一步探索

Fundamentals of Rolling 1st Edition ElsevierRolling Mills: 6 Different Types of Rolling Mills [ImagesP根据热度为您推荐•反馈

Roll Pass Design Methods for Three- and Four-Roll

2019年10月1日To complete the pass design model, elastic mill stand feedback is considered in terms of a fixed elastic modulus for each

Preet Group Preet Group

Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer. Medium Section Rolling Mills

IOM3 Practical Roll Pass Design

2021年6月1日In 2006 he was central to the Scunthorpe long rail rolling project with the development of the new Roll Pass Design for a seven stand continuous finishing mill. From 2009 to 2012 he was the Heavy

Fundamentals of Rolling ScienceDirect

This book discusses as well the different types of rolls for various rolling mills, including blooming, plate, sheet, sheet bar, small section, heavy product, skin passing, and cold rolling mills. The final chapter explains the purpose of roll pass design to ensure the maximum output at minimum cost as well as to reduce the roll wear to a minimum.

Roll Pass Design Methods for Three- and Four-Roll

2019年10月1日Abstract and Figures. In bar and wire rod mills, rolling procedures featuring three-and four-roll technologies are state-of-the-art to produce high-quality long products. While a rolling model for

Preet Group Preet Group

Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer. Medium Section Rolling Mills

(PDF) Wear of hot rolling mill rolls: an overview

1994年8月1日An overview of roll materials is given including adamites, high Cr materials, high speed tool steels and compound rolls. Non-uniform wear, recognised as the most detrimental phenomenon in section

Roll pass design of section mills link.springer

and V. A. Kurdyumova, "Roll Pass Design of Section Mills," which generalizes the vast experience of Soviet metal- lurgy in the field of designs, is timely and needed. The m aterial presented in the book is of great theoretical and practical

SJW Mill Consulting Ltd LinkedIn

Roll Pass Design services for Section Mills. Expertise in the rolling of Profiles, Rails, Sheet PilingHeavy Sections Quality improvement plans, feedstock development, is your feedstock optimal

Rolling of Steel in a Modern Long Product Rolling Mill

2017年6月19日Long product is a common name for (i) reinforcement steel bars, (ii) shaped steel bar products such as rounds, flats, squares, and hexagon etc., (iii) sectional products such as angles (equal and unequal),

Classification of Rolling Mills, Special Types Mill

Classification of mills particularly the division of large group of section mills into heavy, medium and light although is widely used but it is not clearly defined. In rolling of steel three types of intermediate mills are: Its advantage over 3 high is the flexibility of roll pass design avoiding common middle rolls of 3 high stands.

Dmitrii Kinzin Owner and Chief Roll Pass Designer Roll Pass Design

Roll Pass Design Bureau "KINZIN". июнь 2014 настоящее время8 лет 10 месяцев. Челябинская область, Россия. References: 1) R.S.INFRA-TRANSMISSION (India, 2021), Heavy Section Mill design of guide boxes for rolling channel 200; 2) NSS (Egypt, 2021), Heavy Section Mill Roll pass design of

Rollpass Design Solutions

Audit of Roll pass design of Heavy Structural Rolling steel: 36: Monnet Ispat, Raipur: Roll pass design of heavy structural mill: 37: GEC Steel Manufacturing PIC ,UGANDA: Appointed as an adviser/consultant for continuous Section Mill from 01/10/20 for long term. Flats (50-100mm) rolling was recently established with undersigned design.

About us Russula

Russula expands US operations to carry out roll pass design and guidance orientation projects. 2016. 2nd rolling mill supply . Russula supplied second turnkey 350,000 tons/yr merchant bar and section mill to Dojran

Effect of pass schedule and groove design on the metal

The roll grooves in a roller and the roll pass sequence in a hot rolling mill are usually designed based on the type of grades and dimensions of the products and the mill capacity. These have been established over the years based on ana-lytical methods. With modern capability of computer based simulation of the hot deformation process, it is

IOM3 Practical Roll Pass Design 8

2021年6月10日Simon has spent 25 years working in the field of hot rolling of sections, rails and sheet piles. In 2006 he was central to the Scunthorpe long rail rolling project with the development of the new Roll Pass Design for a seven stand continuous finishing mill. From 2009 to 2012 he was the Heavy Section Mill Process Director at Danieli and in

IOM3 Practical Roll Pass Design 4

2021年6月4日Simon has spent 25 years working in the field of hot rolling of sections, rails and sheet piles. In 2006 he was central to the Scunthorpe long rail rolling project with the development of the new Roll Pass Design for a seven stand continuous finishing mill. From 2009 to 2012 he was the Heavy Section Mill Process Director at Danieli and in 2012

Roll Pass Design Methods for Three- and Four-Roll

2019年10月1日Abstract and Figures. In bar and wire rod mills, rolling procedures featuring three-and four-roll technologies are state-of-the-art to produce high-quality long products. While a rolling model for

Preet Group Preet Group

Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer. Medium Section Rolling Mills

(PDF) Wear of hot rolling mill rolls: an overview

1994年8月1日An overview of roll materials is given including adamites, high Cr materials, high speed tool steels and compound rolls. Non-uniform wear, recognised as the most detrimental phenomenon in section

Roll-pass design of structural shapes

ROLL-PASS DESIGN OF STRUCTURAL SHAPES At our works structural shapes are roiled in a 500 mill of-the tandem type, which consists of four stands, three of which (one break-down and two section stands) are three-high mill stands and one is a two-high mill stand. The roils of the break-down stand 500 mm in diameter and with a length of the barrel

Roll pass design of section mills link.springer

and V. A. Kurdyumova, "Roll Pass Design of Section Mills," which generalizes the vast experience of Soviet metal- lurgy in the field of designs, is timely and needed. The m aterial presented in the book is of great theoretical and practical

SJW Mill Consulting Ltd LinkedIn

Roll Pass Design services for Section Mills. Expertise in the rolling of Profiles, Rails, Sheet PilingHeavy Sections Quality improvement plans, feedstock development, is your...

About us Russula

Russula expands US operations to carry out roll pass design and guidance orientation projects. 2016. 2nd rolling mill supply . Russula supplied second turnkey 350,000 tons/yr merchant bar and section mill to Dojran

Dmitrii Kinzin Owner and Chief Roll Pass Designer Roll Pass Design

2) NSS (Egypt, 2021), Heavy Section Mill Roll pass design of beams IPE 300, IPE 400, HE200A, channels UPN 160-280; 3) Emirates Steel (UAE, 2020), Heavy Section Mill Roll...

Rollpass Design Solutions

Rollpass Design Solutions PROJECTS Though our consultancy firm is in nascent stage, from 2014 onwards, but we have given successful consultancy to number of leading industries, like Rastriya Ispat Nigam, Vishakapatnam, Electro steel Steel Ltd. Etc. Our client list is appended below-

Effect of pass schedule and groove design on the metal

The roll grooves in a roller and the roll pass sequence in a hot rolling mill are usually designed based on the type of grades and dimensions of the products and the mill capacity. These have been established over the years based on ana-lytical methods. With modern capability of computer based simulation of the hot deformation process, it is

Classification of Rolling Mills, Special Types Mill

Classification of mills particularly the division of large group of section mills into heavy, medium and light although is widely used but it is not clearly defined. In rolling of steel three types of intermediate mills are: Its advantage over 3 high is the flexibility of roll pass design avoiding common middle rolls of 3 high stands.

IOM3 Practical Roll Pass Design 8

2021年6月10日This included responsibility for the Heavy Section Mill rolls procurement and performance and development of the mill’s product range, including of particular note the Roll Pass Design and commissioning of 700 wide Zed Sheet Piles rolled from beam blank in the tandem mill configuration.

Solving problems on the tube mill The Fabricator

2001年8月16日A good maintenance program, as well as rebuilds or upgrades when necessary, is essential. 6. Mill in misalignment. Tube mill misalignment, poor mill condition, and inaccurate setup account for 95 percent of all problems in tube production. Most mills should be aligned at least once a year. 7. Tooling in poor condition.

Roll Pass Design

ROLL PASS DESIGN OF UNIVERSAL SHAPED SECTION (EQUAL SIDED ANGLE AND CHANNEL) DURATION: 2 to 4 weeks. REQUIRED RAW DATA: Emirates Steel, Heavy Section Mill. Roll Pass Design Specialist. 08.2015 07.2018. 08.2015 07.2018. The engineering company METALLURGMASH Engineering.

- Dls500 High Gradient Magnetic Separator Machine

- 花岗岩熟料鄂破

- Mineral Processing Conveyor Weight Scale

- 石子粉碎机厂家

- 不用炸药可以开采石头的机子

- 矿石粉咋石机器

- Mining Mill That Mounts On Excvator Bucket

- 石灰在铁矿浮选中作用

- What Is Quarrying Of Limestone

- 易拉罐金属粉碎机月饼盒

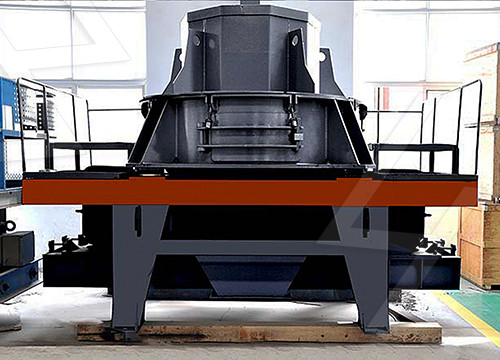

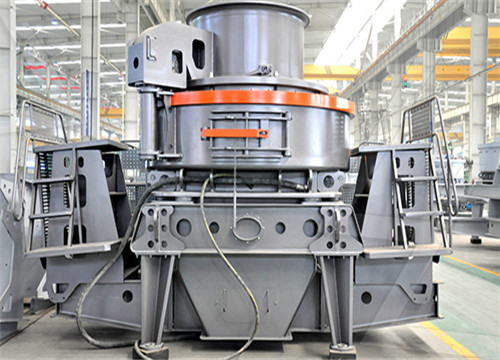

- Sandmax Vertical Shaft Impact Mining Mill

- 博兴付桥杀人案

- 粉煤灰磁珠

- www沈阳破碎机能磨吗?

- 石灰矿锤头破碎机