Iron Ore Processes Flow Charts

Iron processing Definition, History, Steps, Uses,Facts

Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the fourth most abundant element after oxygen,

The six main steps of iron ore processing Multotec

Screening. We recommend that you begin by screening the iron ore to separate fine

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore

DRI production International Iron Metallics Association

DRI production. Direct reduction of iron is the removal of oxygen from iron ore or other iron bearing materials in the solid state, i.e. without melting, as in the blast furnace. The reducing agents are carbon monoxide and

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate

Iron Ore Processing Flowsheet Multotec

Typical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you

Flowchart of iron and steelmaking processes [8]

Iron is converted into steel in the BOF steel making process while EAF process recycles mainly steel scraps. The steel from BOF and EAF can be processed into high grade steels, by passing...

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日The Iron Ore Process Flowsheet The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations. Multi-parallel circuits are necessary, but for

Iron Ore production in the Pilbara Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control are fundamental to the process.

DRI production International Iron Metallics Association

Iron ore is used mostly in pellet and/or lumpy form. The chemical reactions involved in the direct reduction of iron are the following: With H2 3Fe 2 O 3 + H 2 → 2Fe 3 O 4 + H 2 O Fe 3 O 4 + H 2 → 3 FeO + H 2 O FeO + H 2

Iron ore mining and dressing tec-science

2018年6月21日The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From

Iron ore BHP

Iron ore is mixed with coke (from super-heated metallurgical coal) in a blast furnace. Heating Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag.

1A Manufacturing Process for Iron and Steel

The smelting and refining process for iron and steel in the BF-BOF process involves the carbon reduction of iron ore (Fe 2 O 3) in the BF to make molten iron, and decarburization of molten iron in the BOF to

Iron Ore Processing Flowsheet Multotec

Typical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

Flow chart of the mineral processing of hematite

Flow chart of the mineral processing of hematite iron ore. Source publication An intelligent factory-wide optimal operation system for continuous production process Article Full-text...

Iron Ore Processing Flow Sheet multotec

We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Fulltext 01 13 More details on chem Development of a Process

Crude ore Additives Sorted ore Iron ore pellet Slurry Water Bi-products Iron ore pellet sections handling the magnetite flow and one section handle the hematite flow. Together with the hematite flow, a small amount of magnetite is included, so before further processing, the magnetite needs to be separated from the hematite.

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Steel Making Process Complete Overview with Flowchart

Steel Making Process 1. The Bessemer Process 2. The L-D Process 3. The Open Hearth Process 4. The Crucible Steel Making Process 5. The Electric Process 6. Duplex Processes Steel Making Process Flowchart Frequently Asked Questions What is steel process? Which gas is used for manufacture of steel? What did the steel process do?

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which

Blast furnace Definition, Temperature, Diagrams,

2023年1月31日The furnace charge, or burden, of iron-bearing materials (e.g., iron ore pellets and sinter), coke, and flux (e.g., limestone) descends through the shaft, where it is preheated and reacts with ascending

Iron Ore production in the Pilbara Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control are fundamental to the process.

DRI production International Iron Metallics Association

Iron ore is used mostly in pellet and/or lumpy form. The chemical reactions involved in the direct reduction of iron are the following: With H2 3Fe 2 O 3 + H 2 → 2Fe 3 O 4 + H 2 O Fe 3 O 4 + H 2 → 3 FeO + H 2 O FeO + H 2

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Iron ore mining and dressing tec-science

2018年6月21日The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From

1A Manufacturing Process for Iron and Steel

The smelting and refining process for iron and steel in the BF-BOF process involves the carbon reduction of iron ore (Fe 2 O 3) in the BF to make molten iron, and decarburization of molten iron in the BOF to

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日Iron ore pellets are one of the significant sources of iron for iron and steel making due to their superior metallurgical performance, low energy consumption, and less emission of...

Iron Ore Processing Flowsheet Multotec

Typical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you

Iron Ore Processing Flow Sheet multotec

We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Fulltext 01 13 More details on chem Development of a Process

Crude ore Additives Sorted ore Iron ore pellet Slurry Water Bi-products Iron ore pellet sections handling the magnetite flow and one section handle the hematite flow. Together with the hematite flow, a small amount of magnetite is included, so before further processing, the magnetite needs to be separated from the hematite.

Flow chart of the mineral processing of hematite

Flow chart of the mineral processing of hematite iron ore. Source publication An intelligent factory-wide optimal operation system for continuous production process Article Full-text...

How is Steel Made? Steel Production Process (With

Steel manufacturing Principle of the Bessemer Process. The main raw materials for Steel production in a blast furnace are Iron ore, limestone, coke, and some scrap steel. These materials are charged into the blast

Direct reduced iron process tec-science

2018年6月21日The reduction of iron oxides takes place according to the following chemical equations: (1) F e 2 O 3 + 3 C O → 2 F e + 3 C O 2 (2) F e 2 O 3 + 3 H 2 → 2 F e + 3 H 2 O. In contrast to the blast furnace process, the direct-reduced iron process operates at temperatures of up to 1000 °C. The iron ores are therefore not melted!

Seed Planting Flow Chart hldm4.lambdageneration

iron ore processing flow chart Archives Mineral May 9th, 2018 Complete Process Plants Used Buy Sell iron ore beneficiation process flow diagram iron hldm4.lambdageneration 2 / 5. Seed Planting Flow Chart ore processing flow chart BUY Laboratory amp Small Plant Process Equipment

Mineral Processing an overview ScienceDirect Topics

A complete flow diagram, including crushing, grinding, density media separation, froth flotation, and pyrometallurgical and hydrometallurgical process route to achieve the highest purity of metals. PGE, platinum-group elements. Sign in

- 叶腊石粉怎么加工

- Cmaa Class E Mill Duty Limestone Wet Mills For Ore

- 产圆锤破碎机

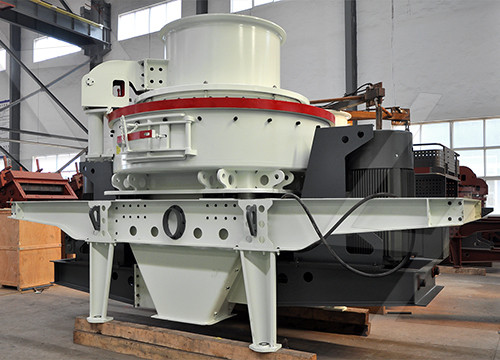

- 制造石打石制砂机

- 查75破石机生产线全套价格

- Supply Quarry Gerik

- 钢渣

- 烟气流速对脱硫系统影响

- 关于h3800圆锥破碎机的文档

- 煤矿磨煤机生产线

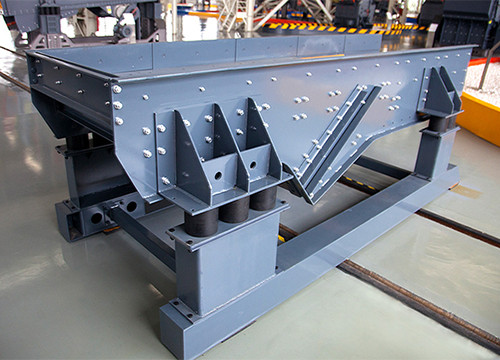

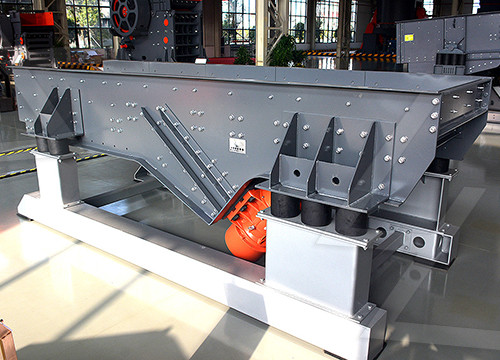

- 河砂筛分机

- Used Closed Circuit Crushing Plant

- Mineral Magnetico Maquina Separadora Seca

- 漳州高岭土在建项目信息

- Proposal Pertambangan Pengolahan Pada Primery Mining Mill