Designing Of Copper Processing Factory

Copper Mining and Processing: Processing Copper Ores Superfund

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling Copper

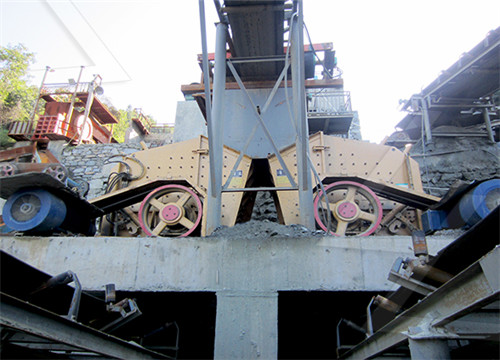

Sulfide ores are generally processed using pyrometallurgy, the extraction and purification of metals by processes involving the application of heat. This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) ele...

IsaKidd™ 2020 Compendium of Technical Papers

section. The design, specification and placement of all lectrode e handling equipment will allow MCM to expand its efinery r production to five tank houses without the need to

Copper Smelting and Refining Process Pan Pacific Copper

The copper concentrates are fed through the flash smelting furnace with oxygen-enriched air. In the furnace, the concentrates are instantly oxidized, after which they melt and separate by their own reaction heat into

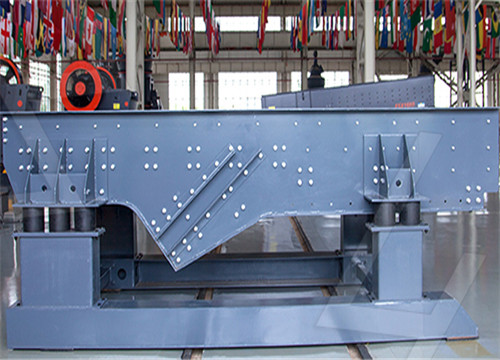

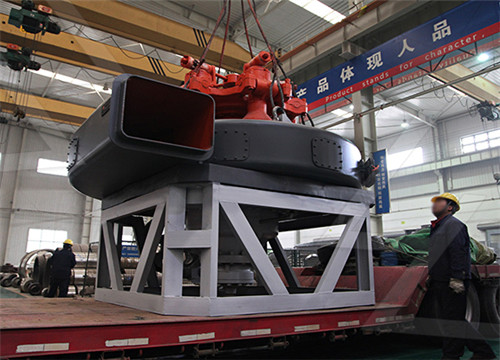

Copper Processing Equipment, Process Flow, Cases

2019年8月23日According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore,

Design for Manufacturing (DFM) Principles Explained

2021年12月1日It clearly defines the part’s design, final quality, manufacturing processes, component materials, ease of distribution, etc. which leads to an extremely well-managed production process that

A Look at the Largest Copper Smelters ThoughtCo

2019年11月20日The copper refinery was commissioned in 1974 by Asarco Inc. and is now owned and operated by Grupo Mexico. 11 of 11 Honorable Mentions Hamburg Refinery (Aurubis)—416kta El Paso

The Industrial Design Process Part 5: The Factory and

2014年7月6日The hands-on role of the designer in the Industrial Design Process is nearly coming to its end for the current year’s production cycle. However, there's still a lot

designing of copper processing factory github

designing of copper processing factory Printed circuit board Wikipedia Copper Processing Plant Design Articles hiaimpolymers How copper is made

steps in designing fish processing factory plant layout

2013年8月29日This is a typical sketch design drawing of a four storey fish processing factory. This drawing consists of the worked out processing plant drawings Fish

Copper processing Roasting, smelting, and

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries. Copper is typically extracted from oxide and sulfide ores that contain between 0.5 and 2.0% copper.

Copper Smelting and Refining Process Pan Pacific

The copper concentrates are fed through the flash smelting furnace with oxygen-enriched air. In the furnace, the concentrates are instantly oxidized, after which they melt and separate by their own reaction heat into

Copper Smelting International Finance Corporation

copper. A double-contact, double-absorption plant should emit no more than 0.2 kg of sulfur dioxide per ton of sulfuric acid produced (based on a conversion efficiency of 99.7%). Emissions Guidelines. Emissions levels for the design and operation of each project must be established through the en-vironmental assessment (EA) process on the ba-

Copper Smelting an overview ScienceDirect Topics

Copper Production. Hong Yong Sohn, Bart Blanpain, in Treatise on Process Metallurgy: Industrial Processes, 2014. 2.1.1.6.1 FeO–Fe 2 O 3 –SiO 2 Slags. It has been customary since early times in copper smelting, when acid refractories were used universally, to add SiO 2 to form a slag with the iron that has been oxidized. This is still the most common

Bund Wall an overview ScienceDirect Topics

Seán Moran, in Process Plant Layout (Second Edition), 2017. 10.8 Bund and Tank Construction. The design of a storage area layout should take account of ground slopes and contours. It is sometimes possible to provide a bund wall on only three sides of the tank if the slope of the ground is sufficient. Esthetically, it is desirable to group all

R8266 040507 Proposal for setting up a processing plant

• To design, improve and preserve the quality of products being endowed by tribal women through scientific processing and technology transfer for value addition. • To enhance the involvement of the tribal women in low cost preservation, processing and packaging of the finished horticulture produces linking them to the market. 3.

steps in designing fish processing factory plant layout

2013年8月29日This is a typical sketch design drawing of a four storey fish processing factory. This drawing consists of the worked out processing plant drawings Fish Processing Plants Cretel Food Processing Equipment Fish processing plant, fish processing equipment, fish plant. meine Beschreibung. Design and installation of

12.3 Primary Copper Smelting US EPA

Copper is produced in the U. S. primarily by pyrometallurgical smelting methods. Pyrometallurgical techniques use heat to separate copper from copper sulfide ore concentrates. Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. 12.3.2 Process Description2-4

TENORM: Copper Mining and Production Wastes US EPA

2023年2月16日The production of copper typically includes the following processes: Leaching Solvent Extraction Smelting Leaching There are two main leaching methods: heap leaching and in-situ leaching. Heap leaching is the most common method used in the U.S. When processing copper through heap leaching, vast quantities of ore and overburden

Designing a resilient and sustainable closed-loop supply chain

2022年1月27日Due to industrialization, copper demand has increased over the last decades. Recycling rate of copper is high and its scrap requires less energy than primary production, so sustainable closed-loop supply chain network design is considered a primary decision. Besides, the uneven distribution of copper has exaggerated the destructive

Materials of construction processdesign Northwestern

2016年2月21日Metals. Carbon steel and stainless steels are some of the most common metals used in construction. Carbon steel is an alloy between carbon and iron. Also known as mild steel, carbon steel is one of the most commonly used engineering materials. It is favored because it is relatively cheap and widely available.

Copper processing Roasting, smelting, and

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and

Materials of construction processdesign

2016年2月21日2 Process Considerations 2.1 Process Temperature and Pressure 2.2 Corrosion 2.2.1 Types of Corrosion 2.3 Cycling 3 Common Materials 3.1 Metals 3.1.1 Material Costs 3.1.2 Stainless Steels 3.1.3

Copper Smelting and Refining Process Pan Pacific

The copper concentrates are fed through the flash smelting furnace with oxygen-enriched air. In the furnace, the concentrates are instantly oxidized, after which they melt and separate by their own reaction heat into

Copper Smelting an overview ScienceDirect Topics

Copper Production. Hong Yong Sohn, Bart Blanpain, in Treatise on Process Metallurgy: Industrial Processes, 2014. 2.1.1.6.1 FeO–Fe 2 O 3 –SiO 2 Slags. It has been customary since early times in copper smelting, when acid refractories were used universally, to add SiO 2 to form a slag with the iron that has been oxidized. This is still the most common

Designing a resilient and sustainable closed-loop supply chain

2022年1月27日Due to industrialization, copper demand has increased over the last decades. Recycling rate of copper is high and its scrap requires less energy than primary production, so sustainable closed-loop supply chain network design is considered a primary decision. Besides, the uneven distribution of copper has exaggerated the destructive

Bund Wall an overview ScienceDirect Topics

Earthen walls are designed such that in cross-section ( Fig. C.1 ), the two sides have a 1 in 1.5 slope, consistent with the angle of repose of the material of which the wall is constructed. Such walls 1 m or more in height should have a flat section at the top not less than 1 m wide.

12.3 Primary Copper Smelting US EPA

Copper is produced in the U. S. primarily by pyrometallurgical smelting methods. Pyrometallurgical techniques use heat to separate copper from copper sulfide ore concentrates. Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. 12.3.2 Process Description2-4

R8266 040507 Proposal for setting up a processing plant

• To design, improve and preserve the quality of products being endowed by tribal women through scientific processing and technology transfer for value addition. • To enhance the involvement of the tribal women in low cost preservation, processing and packaging of the finished horticulture produces linking them to the market. 3.

Estimation of production cost and revenue

2016年3月11日1 Variable Cost of Production 1.1 Raw Materials Cost 1.2 Utilities Cost 1.3 Waste Disposal Costs 2 Fixed Cost of Production 2.1 Labor Costs 2.2 Maintenance Costs 2.3 Research and Development 2.4 Taxes

What is Annealing? A Complete Process Guide TWI

A Complete Process Guide. Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable. The annealing process requires the material above its recrystallization temperature for a set amount of time before cooling.

The List of the Steps to DesignImplement a New Network for

Collect your existing physical and logical network diagrams to support the current state design. Identify routers, switches, LAN uplink bandwidth, network equipment cabinets, power and...

Design Codes Pipework HSE

Design Implementation of Pipework standards Pipes and piping components are normally manufactured to meet the requirements of national standards such as ASME B31 Code for Pressure Piping or BS...

- Granite Edge Wet Grinding Machine

- Hard Rocks Crusher In Jos Plateau State Pakistan

- 办石料厂需要那些机械

- 山东济宁tpb

- 立磨都有什么母材

- Aluminum Processing Plant For Sale Apr

- 生产膨润土机器需要多少钱

- 二手鄂齿破碎齿板

- Crushers To Crushed Rock Into Various Aggregate Sizes

- China High Reputation Sand Making Machine Trader With Iso

- 合作开办采石场

- 活性石灰生产线 价格

- 机头料锤破碎机

- 双辊式破碎机生产图纸

- intitle 圆锥破碎机主轴