Crushed Iron Ore Conveyor Slope

Conveyors Maximum Inclination vs. Product Engineering ToolBox

150 行Maximum conveyor slopes for various materials: Material Maximum Slope (degrees) Acid phosphate 13 Alum 22 Alumina sized or briquette 10 Aluminum sulphate

Conveyors Capacities Engineering ToolBox

134 行Conveyor capacity is determined by the belt speed, width and

Designing a Conveyor System Mineral Processing

2016年4月12日For the average short-centre horizontal conveyor belt, under 300-foot centers, a 4-ply, 28-oz. duck belt may be safely used up

Maximum Conveyor Angle of Inclination Mineral

2016年4月11日The intersection of a vertical line from the*90 ft. HORIZONTAL DISTANCE with a horizontal line from the 24 ft. LIFT

Iron Ore Conveyor Iron Ore Conveyor Products ASGCO

Iron ores are rocks from which metallic iron can be economically extracted. These rocks are usually found in the form of hematite (Fe2O3) or magnetite (Fe3O4). About 98% of world iron ore production is used to make iron

Conveyors in Mining International Mining

2013年10月1日Running at 6 m/sec, the 2 m wide belt conveyor system will carry the ore over almost 12 km. The three principal conveyors, one 9,000 m long tunnel conveyor

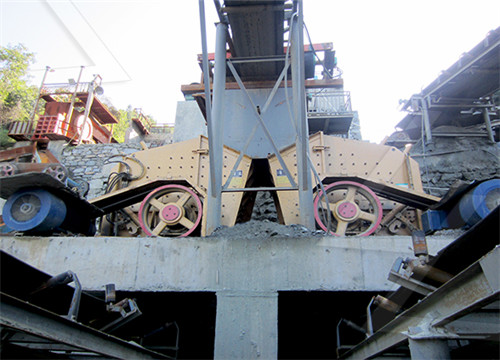

IRON ORE CRUSHING PLANT AND IT'S BELT CONVEYOR

2022年3月20日IRON ORE CRUSHING AND IT'S CONVEYOR LINE II IRON ORE CARRIED BY BELT CONVEYOR #technical_info_fe2o3#conveyor #beltconveyor #crusherplant

Belt conveyor carrying iron ore ll crushed iron ore carried

2022年3月9日crushed iron ore carried by belt conveyor#technical_info_fe2o3#conecrusher #crusherplant #ore #ironore #conveyor

Crushed iron ore conveyor slope Mining Mining Machinery

Crushed iron ore conveyor slope. Jun 30, 2020. Recommended max. conveyor slope (Degree) Material Description Applicable Standard Angle of Surcharge (Degree) Angle of

crushed iron ore conveyor slope

Conveyors Maximum Inclinations for typical Products. 150 行 Iron ore limonite: 28: Iron ore soft: 21: Kaolin pulverized: 32: ore: 20: Walnut shells, crushed: 20: Wheat: 12: Whole

Iron Ore Conveyor Iron Ore Conveyor Products

Sintering is a process used to agglomerate iron ore fines in preparation for blast-furnace smelting and is usually carried out at iron and steelmaking centers. It involves the incorporation of crushed limestone, coke and

Ore Chute Slope Limits and Material Velocity Control Crushing

I am working with a client to develop an ore diversion chute that would catch ore from the discharge of a conveyor that normally fills a coarse ore bin. The chute would redirect to a stacker. Material is 6" minus crushed ore delivered at 270 tonnes/hr, approx SG of 2.3. So the 50 ° suggested by DK is a good start as the slope must be

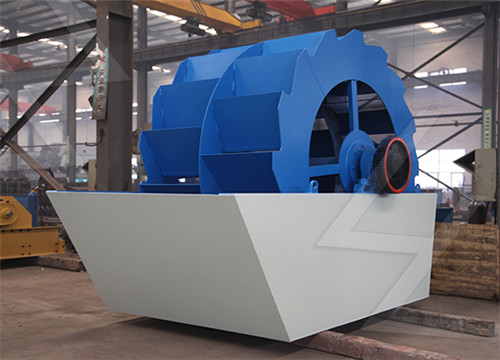

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Conveyors in Mining International Mining

2013年10月1日Crushed stone arrives on trucks and is loaded via a feed conveyor and a chute. The RopeCon system crosses the Nile with a single large rope span between two tower structures positioned on either side of the river. It is not necessary to have a support structure in the river.

Iron Ore: From Mining to Processing to Dust Control

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater than 60% iron is

Mineral Drying FEECO International Inc.

Drying is a critical aspect of mineral processing; throughout the journey from ore to end product, the ability to control moisture content helps to reduce shipping costs, streamline downstream processing, and produce a

Radial Stacker Telescopic Conveyor SKE Industries

SKE Industries KTB1020, KTB1024, KTB1030 Tracked Conveyors: lengths from 20 to 30m, tonnages of 50 to 500tph, feeding size up to 300mm, Fed by other equipment. SKE Industries is a portable stacker conveyor

IRON ORE CRUSHING PLANT AND IT'S BELT CONVEYOR LINE II IRON ORE

2022年3月20日IRON ORE CRUSHING AND IT'S CONVEYOR LINE II IRON ORE CARRIED BY BELT CONVEYOR #technical_info_fe2o3#conveyor #beltconveyor #crusherplant

Belt conveyor carrying iron ore ll crushed iron ore carried by belt

2022年3月9日crushed iron ore carried by belt conveyor#technical_info_fe2o3#conecrusher #crusherplant #ore #ironore #conveyor #beltconveyor #belt #conveyors#boulder

Ferrugination of biocrusts grown on crushed ferricrete: Potential

2021年8月1日The role of biocrusts in surface stabilisation of slopes comprised of crushed ferricrete was examined using three end-member systems: (i) a purely chemical treatment, subjected to periodical addition of ferrous iron; (ii) a purely biological treatment, inoculated with a phototrophic biofilm and fed with a cyanobacterial medium (i.e., BG-11

Feasibility project for implementation of conveyor belts in an iron ore

This article objectifies the implementation of a conveyor belt in an iron ore mine. The mine operational costs of the company Vale S.A. have a tendency to increase in coming years. high strapped slope. Semi-Mobile Crushing System, within the pit with conveyor belts; Mobile Crushing System, within the pit with conveyor belts.

Iron processing Ores Britannica

Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size. Crushed ore is divided into various fractions

crushed iron ore conveyor slope

Conveyors Maximum Inclinations for typical Products. 150 行 Iron ore limonite: 28: Iron ore soft: 21: Kaolin pulverized: 32: ore: 20: Walnut shells, crushed: 20: Wheat: 12: Whole grain: 15: Inclination or Slope Chart. Inclination or Slope Calculator; Use this chart to estimate the inclination or slope angle of a conveyor.

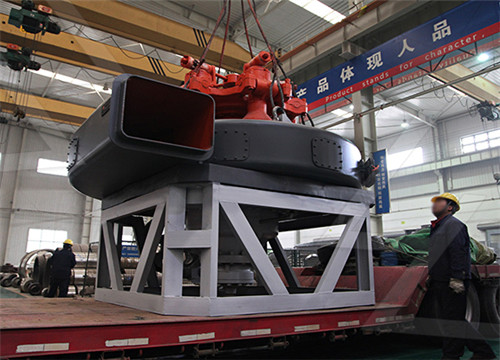

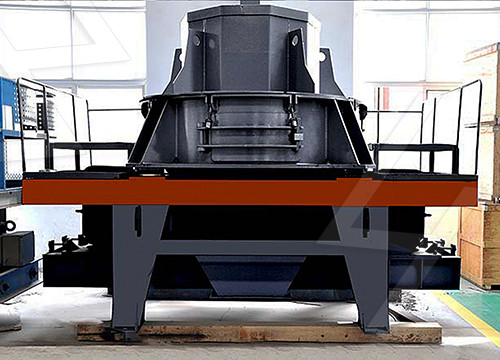

Primary Crusher an overview ScienceDirect Topics

A. Jankovic, in Iron Ore, 2015. 8.2.1. Crushers. Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks. Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw

Feasibility project for implementation of conveyor belts in an iron ore

This article objectifies the implementation of a conveyor belt in an iron ore mine. The mine operational costs of the company Vale S.A. have a tendency to increase in coming years. high strapped slope. Semi-Mobile Crushing System, within the pit with conveyor belts; Mobile Crushing System, within the pit with conveyor belts.

Iron processing Ores Britannica

Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size. Crushed ore is divided into various fractions

Ore Chute Slope Limits and Material Velocity Control Crushing

I am working with a client to develop an ore diversion chute that would catch ore from the discharge of a conveyor that normally fills a coarse ore bin. The chute would redirect to a stacker. Material is 6" minus crushed ore delivered at 270 tonnes/hr, approx SG of 2.3. So the 50 ° suggested by DK is a good start as the slope must be

Crushing in Mineral Processing

2015年12月26日In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Mineral Drying FEECO International Inc.

Iron ore Limestone Lithium Phosphorus Potash Pumice Magnesium Manganese Molybdenum Sand Silica Struvite Talc Vermiculite Zinc Drying Raw Minerals Extracted ore, no matter the mineral, is typically first

Radial Stacker Telescopic Conveyor SKE Industries

SKE Industries KTB1020, KTB1024, KTB1030 Tracked Conveyors: lengths from 20 to 30m, tonnages of 50 to 500tph, feeding size up to 300mm, Fed by other equipment. Request A Quote Read More SKE Industries is a

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Ferrugination of biocrusts grown on crushed ferricrete: Potential

2021年8月1日The role of biocrusts in surface stabilisation of slopes comprised of crushed ferricrete was examined using three end-member systems: (i) a purely chemical treatment, subjected to periodical addition of ferrous iron; (ii) a purely biological treatment, inoculated with a phototrophic biofilm and fed with a cyanobacterial medium (i.e., BG-11

crushed iron ore conveyor slope

crushed iron ore conveyor slope. Ver artículo. On the right is a two million ton heap of crushed, conveyor-stacked ore placed on a plastic-lined leach pad. Pregnant and barren solution storage ponds are located downslope from the heap. Buildings include process plant, laboratory, maintenance shop and administration offices.

Primary Crusher an overview ScienceDirect Topics

A. Jankovic, in Iron Ore, 2015 8.2.1 Crushers Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks. They come in many varieties, and a summary of different crusher types is provided in Table 8.1. Table 8.1. Comparison of different crusher types

How to design an iron ore conveyor? linkedin

2023年3月7日Here are the steps you can follow to design an iron ore conveyor: Determine the capacity requirements: The first step is to determine the amount of iron ore that needs to be transported over a

Iron Ore AnalysisProcess Optimization Solutions

2017年7月27日Our solutions monitor the complete iron making processes from the direct analysis on conveyor belts towards laboratory analysis and complete automated quality control of iron ore, iron sinter, direct reduced iron, pig iron and iron ore pellets. During the entire iron ore production process, we deliver tailored analytical solutions for

Underground hard-rock mining Wikipedia

Typically, long hole mining requires two excavations within the ore at different elevations below surface, (15 m 30 m apart). Holes are drilled between the two excavations and loaded with explosives. The holes are blasted and the ore is removed from the bottom excavation. Ventilation [ edit] Door for directing ventilation in an old lead mine.