Vertical Roller Mill Mohs Hardness

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard materials. They can also be used to prepare feed for systems producing ultra-fine

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic

Vertical Roller Mill mpl Ultrafine Powder Technology

2021年11月5日Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, can grind stones with a Mohs hardness below 7 +

Vertical Roller Mills

Vertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal,

How to choose between ball mill and vertical roller mill?

2022年6月24日The vertical roller grinding mill is mainly suitable for superfine powder processing of non-flammable and explosive brittle materials with medium and low

Mohs scale Wikipedia

The Mohs scale of mineral hardness (/ m oʊ z /) is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to

Mineral’s Hardness and Mohs Scale of Mineral Hardness

Mohs hardness is often mentioned Mill Machinery. It is a kind of relative hardness, proposed by the German mineralogist Mohs (Frederich Mohs) in 1824. ,vertical roller

Vertical Roller Mill for Phosphorite Grinding

2020年4月10日〖Pulverizing field〗: For various non-metallic mineral materials with Mohs hardness below 7 and humidity within 6%, this mill is widely used in power, metallurgy,

Moh’s Hardness Of Clinker Crusher Mills

The Mohs hardness is 3.5 to 4 and the specific gravity is 2.85. and non-explosive mineral materials with Mohs white lime, cement clinker, activated carbon, Cone

Vertical roller mills: The new leader in grinding technology

2019年10月11日The Loesche VRM has adaptable grinding modules which are already proven to be the way forward in other mining industries, allowing for variant mineral ores

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard materials. They can also be used to prepare feed for systems producing ultra-fine materials, such as a Raymond® Vertical mill, ball mill or Jet-Stream™ Classifier system.

IOP 287 Praveen Purshottaaim Parieek Institute of Physics

Increase productivity of vertical roller mill using seven QC tools Praveen Pareek1 and Dr. Vijayendra Singh Sankhla1 1 Department of Mechanical Engineering, GITS, Udaipur, Clinker's parameters plays a vital role in productivity of mill, viz it's hardness, size, composition. If clinker size is too small (Too fine like powder) it will not

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

Atlas. Vertical Roller Mill. NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to medium-hard materials. ProductsSolutions Dry Grinding Atlas Vertical Roller Mill. The Atlas is a roller air-swept mill designed for continuous operation with minimum maintenance.

Advantages and disadvantages of vertical roller mill

Vertical roller mill (vertical grinding mill) is mainly suitable for ultra-fine powder processing of non-inflammable and non-explosive brittle materials with medium and low hardness and Moh’s hardness of 6. The main disadvantages of vertical roller mills are: (1) Since the finished product is sent by the wind, the composition of the finished product composition

mpl Automatic mills All the products on DirectIndustry

Raymond vertical for limestone Final grain size: 45 µm 1,600 µm Rotational speed: 83 rpm Output: 10 t/h 35 t/h Based on traditional MTW European type Trapezium Mill, this Heavy type grinding mill is launched to the market by adopting European innovation concept and international advanced technology. It is a new Raymond grinding mill 4R3216

Best HLM Vertical Roller Mill Manufacturer and Factory

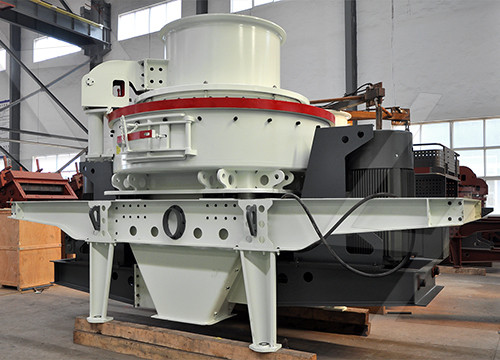

HLM series vertical roller mill machine has the advantages of higher grinding efficiency, lower consumption, larger feeding size, ease of fineness adjustment, lower operating cost, space saving, low noise, wear-resisting, environmental protection, and etc.

Chapter Six: Some Operating Guidelines Vertical Roller Mill

2022年4月6日This setting is mainly important when the material hardness varies a lot. In the VRM, you will see that the differential pressure (ΔP) is perhaps the most important operational parameter after...

Mineral’s Hardness and Mohs Scale of Mineral Hardness

Mohs hardness is often mentioned Mill Machinery. It is a kind of relative hardness, proposed by the German mineralogist Mohs (Frederich Mohs) in 1824. ,vertical roller mill,vertical grinding machine,vertical grinding mill,vertical mill machine,vertical mill product line,vertical roller grinding mill and so on. They are widely used in the

sbmchina/sbm verticl impact mica powder grinding mill.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

China Environmentally Friendly Desulfurization Limestone Vertical Mill

China Environmentally Friendly Desulfurization Limestone Vertical Mill ISO Certificati, Find details about China Limestone Vertical Mill from Environmentally Friendly Desulfurization Limestone Vertical Mill ISO Certificati Hefei Hengcheng

What is the difference between a ball mill and a Raymond mill?

2023年3月2日Raymond mill adopts a roller grinding ring for grinding, which is suitable for processing non-metallic minerals with Mohs hardness below 7, such as gypsum, limestone, calcite, talc, kaolin, coal, etc.

Vertical Roller Mills

Vertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

Mohs Scale In Machine Tool Crusher Mills

On the Mohs scale it does show hardened . Fused Silica can be machined with diamond tools but it will chip . Soapstone Countertop. A Great Choice For Many Reasons. Talc is 1 on the Mohs scale, diamonds are 10 on this scale. Therefore it's relatively soft, when compared to granite or marble, and easy to machine and tool.

quadropol® vertical roller mill thyssenkrupp-polysius

Vertical roller mill gearbox forces only in vertical direction due to arrangement, vibration level < 0.5 mm/s No extensive scaffolding necessary for maintenance work, considering OSH regulation Changing roller tyre within two shifts on pylon Highest mill compound availability and reliability Efficient grinding low specific power consumption

IOP 287 Praveen Purshottaaim Parieek Institute of Physics

Increase productivity of vertical roller mill using seven QC tools Praveen Pareek1 and Dr. Vijayendra Singh Sankhla1 1 Department of Mechanical Engineering, GITS, Udaipur, Clinker's parameters plays a vital role in productivity of mill, viz it's hardness, size, composition. If clinker size is too small (Too fine like powder) it will not

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

Atlas. Vertical Roller Mill. NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to medium-hard materials. ProductsSolutions Dry Grinding Atlas Vertical Roller Mill. The Atlas is a roller air-swept mill designed for continuous operation with minimum maintenance.

Advantages and disadvantages of vertical roller mill

Vertical roller mill (vertical grinding mill) is mainly suitable for ultra-fine powder processing of non-inflammable and non-explosive brittle materials with medium and low hardness and Moh’s hardness of 6. The main disadvantages of vertical roller mills are: (1) Since the finished product is sent by the wind, the composition of the finished product composition

mpl Automatic mills All the products on DirectIndustry

Raymond vertical for limestone Final grain size: 45 µm 1,600 µm Rotational speed: 83 rpm Output: 10 t/h 35 t/h Based on traditional MTW European type Trapezium Mill, this Heavy type grinding mill is launched to the market by adopting European innovation concept and international advanced technology. It is a new Raymond grinding mill 4R3216

Mineral’s Hardness and Mohs Scale of Mineral Hardness

2020年6月23日Division standards of all kinds of mineral hardness in Mill machinery: Hardness: Because this test is destructive to materials, it can only be made on the Mohs hardness is often mentioned Mill Machinery. It is a kind of relative hardness, proposed by the German mineralogist Mohs (Frederich Mohs) in 1824. Vertical Roller Mill (600

Chapter Six: Some Operating Guidelines Vertical Roller Mill

2022年4月6日This setting is mainly important when the material hardness varies a lot. In the VRM, you will see that the differential pressure (ΔP) is perhaps the most important operational parameter after...

Mineral’s Hardness and Mohs Scale of Mineral Hardness

Mohs hardness is often mentioned Mill Machinery. It is a kind of relative hardness, proposed by the German mineralogist Mohs (Frederich Mohs) in 1824. ,vertical roller mill,vertical grinding machine,vertical grinding mill,vertical mill machine,vertical mill product line,vertical roller grinding mill and so on. They are widely used in the

sbmchina/sbm verticl impact mica powder grinding mill.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Vertical Roller Grinding Machine Roller Assembly

Vertical mill grinding roller is the main component for rolling and grinding machine.The number of grinding rollers in vertical grinding is mainly 3-6 because of different production capacity. Each grinding roller is m ounted on the same shaft and rotates at different speeds to achieve a good grinding effect.

China Environmentally Friendly Desulfurization Limestone Vertical Mill

Leave a Message. we will call you back quickly!

3 rollers calcium carbonate grinding mill Popular 3 rollers

3 rollers calcium carbonate grinding mill Manufacturers Directory find 42 3 rollers calcium carbonate grinding mill from 3 rollers calcium carbonate grinding mill online Wholesalers for your sourcing needs from China. This kind of roller mill is mainly used to grind any non-metal minerals with Moh’s hardness less than 7, for example

brinal hardness of the roller use for mixing in las

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

quadropol® vertical roller mill thyssenkrupp-polysius

Vertical roller mill gearbox forces only in vertical direction due to arrangement, vibration level < 0.5 mm/s No extensive scaffolding necessary for maintenance work, considering OSH regulation Changing roller tyre within two shifts on pylon Highest mill compound availability and reliability Efficient grinding low specific power consumption

What is the difference between a ball mill and a Raymond mill?

2023年3月2日Raymond mill adopts a roller grinding ring for grinding, which is suitable for processing non-metallic minerals with Mohs hardness below 7, such as gypsum, limestone, calcite, talc, kaolin, coal, etc.