Linner Plate Of Impect Mining Mill

Mill liners Metso Outotec

Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, charge, expected service life, and ore properties. With

进一步探索

Mill Liners MultotecAll Metso Corporation catalogs and technical brochures Dir根据热度为您推荐•反馈

Magnetic Wear Liners: MagLiners™ MiningMinerals

MagPatch is a magnetic patch liner that is a simple yet powerful solution for quick, temporary repairs to holed or damaged material handling equipment. CorroCube® The

进一步探索

Frequently Asked Questions About Magnetic Wear LinersKryptane® Urethane Magnetic Wear Liners • BulkInside根据热度为您推荐•反馈

SAG Mill Liner Design Mineral ProcessingMetallurgy

2016年6月6日The shell liner lift is usually 125-175 mm (5-7 in.) over a 63-75 mm (2.5-3 in.) plate. This amount of lift gives adequate cascade

Poly-Met mill liners Mill linings from rubber and steel

Low weight with long wear life. Metso Outotec's Skega Poly-Met™ mill linings combine the most desirable properties of rubber and steel to maximum advantage. This combination allows the use of more wear

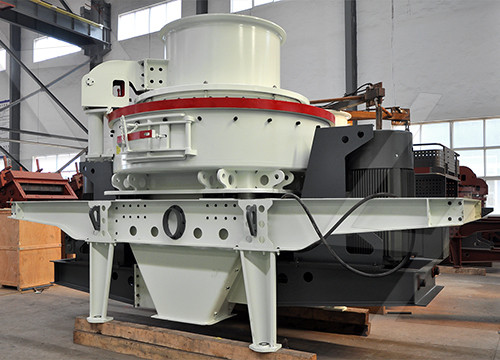

Impact Liner Plate China Manufacturers, Suppliers, Factory

Impact Liner Plate; Impact Liner Plate China Manufacturers, Suppliers, Factory. All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over

Grinding Mill Liners Mineral ProcessingMetallurgy

2015年8月6日The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball

Mining Mill Liner Ceresist Materials Co., Ltd.

The liner is an important part of the grinding machine. The lifting liner lifts the material to a certain height, the impact of the free fall, and the friction effect between the friction

China Wear risistant ball mill liners plate impact liner

Overview: Type Bowl bar Origin China HS Code Condition New Applicable Industries EnergyMining Machine Type Impact Crusher Certification ISO 9001:2008

Mill Lining Systems FluidHandling Trelleborg

Shell Plate Liners Trelleborg shell plate liners are designed to complement the lifter bar operation for ball mills, rod mills and drum scrubbers. The thickness of the shell plate may be varied and optimized to match the

Impact Resistant Linings I Wear Liners Multotec

Available globally, our Impact Resistant Linings feature: High-velocity impact and sliding wear Tailored shape, size and thickness for your application Steel, rubber and polyurethane composite assemblies

Ceramic Wear Liners: CorroCeramic™ Mining

With over 35 years of expert experience designing and producing ceramic linings, Corrosion Engineering’s ceramic liners are well-known and trusted for their ability to reduce costs, achieve longer service life, improve

Magnetic Wear Liners: MagLiners™ MiningMinerals Processing

MagPatch is a magnetic patch liner that is a simple yet powerful solution for quick, temporary repairs to holed or damaged material handling equipment. CorroCube® The CorroCube range of ceramic cube wear liners offers unrivaled wear and abrasion resistance for applications exposed to large materials and extreme impact velocities. CorroTile®

CCONIHARD WEAR LINERS RexLine Engineering

As a genuine mining and quarrying wear liner support service, REXLINE™ have excellent quality CCO plate and weld wires. The microstructure of Cr7C3 carbide volume fraction is 50% or more which makes it one of the

Simple Ore Extraction: Choose A Wholesale impact mill liner plate

Explore our mining equipment to find the ideal wholesale impact mill liner plate model and mills for any mining challenge.; MENU MENU Alibaba Alibaba Categories Sign in. Join for free. Messages. Orders. Cart. Categories. Ready to Ship Impact Mill Liner Plate (75 products available) 1/6.

Ball Mill Liner Design Mineral ProcessingMetallurgy

2016年1月5日For 60 mm (2.5″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately 13.1 D in meters (for D in feet, divide 13.1 D by 3.3).

Impact Liner Plate China Manufacturers, Suppliers, Factory

Getting started; Impact Liner Plate; Impact Liner Plate China Manufacturers, Suppliers, Factory. All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the stuff packaging and environmental defense for Impact Liner Plate, Gold Grinding Mill, Cone Crusher Concave, Mining Machinery Parts,relining.We would

Mining Mill Liner Ceresist Materials Co., Ltd.

However, the impact toughness of high-chromium cast iron is still relatively low (usually 5~7 J/cm2), so high-chromium cast iron is only suitable for the mining of small-size liners and large-size liners in cement mills Wet small-diameter mills (diameters below 2.5 m) are not suitable for large-diameter mills with large impact strength

Semi-autogenous grinding (SAG) mill liner design and

the impact of shell liners on the grinding action and of grates and pulp lifters on pulp discharge. In recent years, the trend in large SAG mills has been to use wide-spaced shell lifters with large lifter face angles, primarily to reduce packing and ball/liner damage, and to use larger, hence fewer, mill liner parts to reduce downtime at liner

Mining Fundiciones Estanda

ESTANDA offers services and products in the MINING sector through a comprehensive offer of steels and alloys for the processes to break up and pulverise rocks and minerals in mines.. Wide choice of selected own Steels resistant to wear, impact, and abrasion:; High chromium (white iron steels); Chrome-Molybdenum steels: perlitic and martensitic.

Qiming Machinery Wear Parts For Mining, QuarryingCement

Qiming Machinery manufactures replacement wear parts for Mining, QuarryingCement Industry plants, includes crusher wear parts, mill liner. Skip to content. 0086 which products include impact crusher blow bars, impact plates, feed tube, VSI wear parts, mill liners, distributor plate, and other wear parts.

Ball Mill Liner Plate Luoyang Yujie IndustryTrade Co.,Ltd

Ball Mill Liner Plate is used for protecting ball mill cylinder against the impact of grinding medium and ore. At the same time, taking advantage of different forms of high manganese steel liner to adjust the motion state of the grinding media to enhance the crushing effect of grinding materials, which help to improve mill grinding efficiency, increase productivity,

Jan Lux tee, trusted suppliers of wear resistant liners for the mining

teeindustries.co.za : The Engineering Establishment (tee) is a trusted supplier of custom components for mining mills. Jan Lux heads up tee. His 20+ years of experience in the field is unmatched in sub-Saharan Africa. Suppliers of: Liner plates, Rubber liners, Chute liners, liner plate for rollers, liner plate for crushers, Flotation spares, Ceramic

How to Replace the Ball Mill Liner? linkedin

2019年7月4日The hoisting ball mill liner is responsible for the hoisting work, and the lifting process needs to pay attention to the operation of the wire rope and the hook. The new liner of the ball...

Ceramic Wear Liners: CorroCeramic™ Mining

Ceramic liners from Corrosion Engineering have a proven history of being highly effective and long-lasting in mining equipment such as chutes, hoppers, transfer points, and conveyors with extreme operating

Qiming Machinery Wear Parts For Mining, QuarryingCement

Qiming Machinery manufactures ASTM A532M standard chromium steel wear parts over 4,000 tons per year, which products include impact crusher blow bars, impact plates, feed tube, VSI wear parts, mill liners, distributor plate, and

Simple Ore Extraction: Choose A Wholesale impact mill liner plate

Explore our mining equipment to find the ideal wholesale impact mill liner plate model and mills for any mining challenge.; MENU MENU Alibaba Alibaba Categories Sign in. Join for free. Messages. Orders. Cart. Categories. Ready to Ship Impact Mill Liner Plate (75 products available) 1/6.

Poly-Met mill liners Mill linings from rubber and

Low weight with long wear life. Metso Outotec's Skega Poly-Met™ mill linings combine the most desirable properties of rubber and steel to maximum advantage. This combination allows the use of more wear

Ball Mill Liner Design Mineral ProcessingMetallurgy

2016年1月5日For 60 mm (2.5″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately 13.1 D in meters (for D in feet, divide 13.1 D by 3.3).

Impact Liner Plate China Manufacturers, Suppliers, Factory

Getting started; Impact Liner Plate; Impact Liner Plate China Manufacturers, Suppliers, Factory. All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the stuff packaging and environmental defense for Impact Liner Plate, Gold Grinding Mill, Cone Crusher Concave, Mining Machinery Parts,relining.We would

Mining Mill Liner Ceresist Materials Co., Ltd.

The liner is an important part of the grinding machine. The lifting liner lifts the material to a certain height, the impact of the free fall, and the friction effect between the friction between the materials, so that the materials are crushed and finely ground. The shape of the end cover lining board is relatively special.

Semi-autogenous grinding (SAG) mill liner design and

the impact of shell liners on the grinding action and of grates and pulp lifters on pulp discharge. In recent years, the trend in large SAG mills has been to use wide-spaced shell lifters with large lifter face angles, primarily to reduce packing and ball/liner damage, and to use larger, hence fewer, mill liner parts to reduce downtime at liner

Ball Mill Liner Plate Luoyang Yujie IndustryTrade

Ball Mill Liner Plate is used for protecting ball mill cylinder against the impact of grinding medium and ore. At the same time, taking advantage of different forms of high manganese steel liner to adjust the motion state

Mining Fundiciones Estanda

MILLING Process: Liners and grate plates for SAG mills, AG, ball mills, rod mills CRUSHING Process: Components for crushers, hammers, blowbars, wear plates Mill Liners Metallic liners for all kind of SAG mills, AG, ball mills and rod mills present in the grinding processes of minerals.

Jan Lux tee, trusted suppliers of wear resistant liners

teeindustries.co.za : The Engineering Establishment (tee) is a trusted supplier of custom components for mining mills. Jan Lux heads up tee. His 20+ years of experience in the field is unmatched in sub-Saharan Africa.

DEPARTMENT OF MINING ENGINEERING UNIVERSITY OF

III-135 Profile Gauge: A quantitative technique is the physical measurement of the mill liners using a profile gauge. It appears that the rubber liner manufacturers were

Wear Plates Cutting Edges

Wear plates are expendable items that are used to prevent excessive wear or damage to expensive equipment. Cutting Edges provides all of its wear plates with utmost focus on exceeding the industry’s most stringent standards. If you’re looking for dependable steel overlay plates from a customer-oriented manufacturer who will work one-on-one

(PDF) A structured approach to modelling SAG mill liner wear

2011年1月1日The reduced work efficiency caused by the wear and deformation of the liner, and the system shutdown caused by the replacement of the liner, greatly affect production efficiency. According to...