Main Traits Of Mobile Jaw Crusher

Jaw Crusher an overview ScienceDirect Topics

crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual

进一步探索

Estimate Jaw Crusher Capacity Mineral ProcessingMeJaw Crusher ComponentsParts Mineral Processing根据热度为您推荐•反馈

Mobile Jaw Crusher RUBBLE MASTER

根据热度为您推荐•反馈

Characteristics and Comparison of Four Types of Jaw

2023年2月15日Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc). Thus, its price is higher than

Types of Crushers: What You Need to Know Machinery Partner

The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits. Primary crushing involves using a large object as the initial

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

Mobile Crushers Mineral ProcessingMetallurgy

2015年12月23日A mobile crusher is a completely self-contained unit mounted on a frame, which is moved, by means of a transport mechanism, along the wall of the mine pit as mining progresses. Excavated rock is

Mobile Crusher Plant For Mobile Crushing And Screening

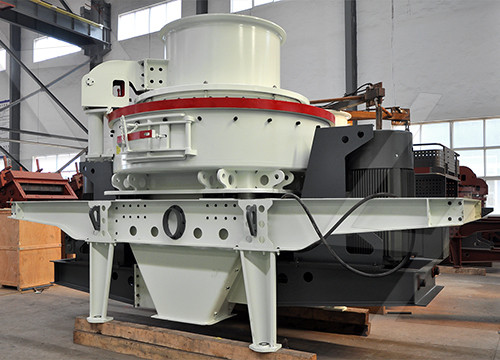

Characteristics of impact mobile crusher plants 1. The mobile crushing machine adopts intelligent, integrated, and modular configuration, with excellent site passability. The

Mobile Jaw Crusher

Mobile jaw crusher characteristics: The hydraulic drive of mobile jaw crusher is strong, featuring with high-performance single-elbow jaw crushing machine, large crushing ratio, and high output. The automatic

Main Traits of Mobile Jaw Crusher sanmechina

Mobile jaw crusher is entirely adjustable to all mobile crushing calls for. It arranged new assortment of company possibilities for contractors, quarry operators, recycling and

Mobile crushers Metso Outotec

Lokotrack® crushers are more customizable and the range is wider, covering mobile cone, impact and jaw crushers. Nordtrack™, on the other hand, is ideal if you work in short-term contracting jobs or are just starting your own operations. The family consists of two mobile jaw crusher models and one mobile impact crusher.

Lokotrack® LT116™ mobile jaw crusher Metso Outotec

High capacity with Lokotrack® LT116™ mobile jaw crusher. Lokotrack® LT116™ mobile crusher is a versatile primary jaw crushing plant. It's a perfect fit with other Metso mobile units in multistage crushing processes. Lokotrack® LT116™ is mounted on tracks so it can be easily moved inside a quarry or a construction site and transported

Jaw Crushers Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single

Types of Crushers: What You Need to Know Machinery Partner

The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits. Primary crushing involves using a large object as the initial force to break down very large and hard rocks and boulders into smaller pieces before they move onto the secondary stage.

Mobile Crushers Mineral ProcessingMetallurgy

2015年12月23日Gyratory Crushers. Hammer Mills. Impact Crushers. Roll Crushers. Better than 70% of mobile crushers are installed in limestone operations with around 15% being gyratory, 30% hammer,

Crawl Mobile Jaw Crusher Senya Crushers

CHARACTERISTICS Hydraulic drive, rugged, high-performance single toggle plate jaw crusher is with big crushing ratio and high yield. The feeder with powerful vibration can adjust the speed automatically, making the mainframe operating at full capacity, to achieve the desired productivity

Lokotrack LT3054 Mobile Jaw Plant Garriock Bros.

Main features of the Lokotrack LT110 are: Modern, modular design for easy use and service. Proven C3054 jaw crusher. Several feeder options. Newest process controlling with IC700 automation system. Wide range

Main Traits of Mobile Jaw Crusher sanmechina

Mobile jaw crusher is entirely adjustable to all mobile crushing calls for. It arranged new assortment of company possibilities for contractors, quarry operators, recycling and mining apps. This kind of crusher device can do aside with the obstacle of the crushing locations and scenarios, and provide you the large overall performance and minimal selling price

sbm/sbm five characteristics of mobile jaw crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Multiple Types of Mobile Crusher for Your Best

Mobile crusher can also be called mobile crushing station, which is inevitable product under the new era of high-tech crushing technology. Its main characteristics are a mobile operation, walking freely, more

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the...

MC 100i EVO Mobile jaw crushers mpl Wirtgen Group

Properties. The smallest mobile jaw crusher of the EVO line impresses with its compactness and reliability. It can be used for a huge variety of materials, offering wide-ranging possibilities for both demolition companies and contract crushers. Thanks to the diesel direct drive, the MC 100i EVO is economical in consumption.

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Mobile Jaw Crusher For Sale Mobile Jaw Crusher Plant AGICO

The mobile jaw crusher adopts a mobile frame as the carrier of the entire crushing unit, and the equipment is pulled in and out of the work site by the front car, which is simple to install, convenient and flexible. Main conveyor belt model: B800×8.5M: B1000×9.5M: B1000×11M: B1200×11M: Side conveyor belt model (optional) B500×3M: B650

Mobile crushers Metso Outotec

Lokotrack® crushers are more customizable and the range is wider, covering mobile cone, impact and jaw crushers. Nordtrack™, on the other hand, is ideal if you work in short-term contracting jobs or are just starting your own operations. The family consists of two mobile jaw crusher models and one mobile impact crusher.

MC 120i PRO Mobile jaw crushers mpl Wirtgen Group

The jaw crusher MOBICAT MC 120 PRO is extremely robust and impresses with its low-maintenance operation. The machine also guarantees high production outputs. 1 / 2 Intuitive control concept SPECTIVE for simple operation The easy-to-operate control concept SPECTIVE allows the machines to be operated at a touch panel.

MC 100i EVO Mobile jaw crushers mpl Wirtgen Group

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft. The material is crushed by the elliptic course of movement and falls down due to gravity.

Jaw Crushers Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single

Mobile Crushers Mineral ProcessingMetallurgy

2015年12月23日Gyratory Crushers. Hammer Mills. Impact Crushers. Roll Crushers. Better than 70% of mobile crushers are installed in limestone operations with around 15% being gyratory, 30% hammer,

Lokotrack LT3054 Mobile Jaw Plant Garriock Bros.

The crusher has unique characteristics enabling it to crush even the hardest rock at a small, closed-side setting at high capacity. To meet your exact application requirement, the Lokotrack LT3054 can be equipped

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the...

sbm/sbm five characteristics of mobile jaw crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Mobile Crushing Plant Mobile Crusher Plant For Sale

CONSTMACH “mobile jaw and impact crushers” are used for crushing wide range of rocks from limestone to basalt. Presence of primary jaw crusher enables to crush big and hard rocks. On the other hand, thanks

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Lokotrack® LT116™ mobile jaw crusher Metso Outotec

High capacity with Lokotrack® LT116™ mobile jaw crusher. Lokotrack® LT116™ mobile crusher is a versatile primary jaw crushing plant. It's a perfect fit with other Metso mobile units in multistage crushing processes. Lokotrack® LT116™ is mounted on tracks so it can be easily moved inside a quarry or a construction site and transported

Mobile Jaw Crusher For Sale Mobile Jaw Crusher Plant AGICO

The mobile jaw crusher adopts a mobile frame as the carrier of the entire crushing unit, and the equipment is pulled in and out of the work site by the front car, which is simple to install, convenient and flexible. Main conveyor belt model: B800×8.5M: B1000×9.5M: B1000×11M: B1200×11M: Side conveyor belt model (optional) B500×3M: B650

In- depth Components of a Jaw Crusher PROPEL INDUSTRIES

2021年6月14日The fixed jaw face is opposite to the pitman face and is statically mounted. It is also covered with a manganese jaw plate. Manganese liners (Jaw plate) protects the frame from wear. These include the main jaw plates covering the frame opposite the moving jaw and the cheek plates which line the sides of the crusher body within the crushing

Mobile Jaw Plants Astec

Overview. Our mobile jaw plants are built for maximum jaw crushing mobility. Featuring Pioneer ® Series Jaw Crushers, these plants offer up to 25 percent more capacity than competitive models and are equally effective in aggregate or recycling applications. These plants allow stationary and portable producers to benefit from on-site mobility.