Potash Ore Processing

Sylvinite, Other Potash Ore Processing SpringerLink

Now, however, in most plants the ore is first ground to a size where the potash is liberated from the halite, it is “deslimed” to remove the

Mining Potash for Fertilizer Advancing Mining

2014年6月26日Today, potash comes from either underground or solution mining. Underground potash deposits come from evaporated sea beds.

Potash Wikipedia

OverviewHistory of productionTerminologyProductionOccupational hazardsConsumptionSee alsoFurther reading

Potash (especially potassium carbonate) has been used in bleaching textiles, making glass, ceramic, and making soap, since the Bronze Age. Potash was principally obtained by leaching the ashes of land and sea plants. Beginning in the 14th century potash was mined in Ethiopia. One of the world's largest deposits, 140 to 150 million tons, is located in the Dallol area of the Afa

进一步探索

What Is Potash and What Is It Used For? CG Lawn5 Things To Know About Potash Investopedia根据热度为您推荐•反馈

23. POTASH Europa

The processing of potash ores comprises four stages: (1) potash ore is crushed and ground to release the potash minerals from the ore, at this stage clay minerals are also

The Potash Drying Process: What You Need to Know

Mined potash requires processing in order to make the potassium readily available for plant consumption and to create a product suitable for

Potash Mining and Processing Infographic eKonomics

Potash is a general term used to describe a variety of potassium (K) containing fertilizers used in agriculture.; The term potash comes from an early production technique where

A General History of Potash Processing FEECO

FEECO has been processing potash for over 60 years, helping the agriculture industry to bring better products to market to meet growing demands. From potash dryers and compaction granulation circuits, to

Potash Processing in Saskatchewan CIM Bulletin

Liberation in the Esterhazy member ores is substantial at 9.5 mm, and for the Patience Lake member ores is 1.2 mm. Potash, like most industrial minerals, is sold based both on its

Potash Flotation Process Mineral ProcessingMetallurgy

2016年5月6日Potash occurs in soft deposits generally associated with sodium chloride and varying amounts of clay slime, which because of its colloidal character, complicates the beneficiation process. Potash ores

Potassium analyser for the potash industry Berthold

Potassium content measurement for the potash industry is one of the most difficult and challenging measurements in the mining industry. It is however essential in the potash

Potash: Deposits, Processing, Properties and Uses SpringerLink

Sylvinite, Other Potash Ore Processing. Donald E. Garrett; Pages 325-402. Brine Processing Operations. Donald E. Garrett; Pages 403-439. Non-Chloride Products. Donald E. Garrett; sulfate of potash, etc. When referring to ores, or in geology, all of the naturally found potassium salts are called "potash ores". However, originally potash

Engineering designs for potash processing facility

2022年12月31日Processing the potash, however, will require a change from commonly used methods. Ore in the Khemisset basin contains iron and magnesium, and removing those metals requires an extra processing step. In addition, the ore’s complex chemistry requires different approaches to managing brine.

Potash Ore Market Designing Africa's First Potash Processing

2022年12月13日Processing that potash, however, will require a change from commonly used methods due to its mineral content. Ore in the Khemisset basin contains iron and magnesium, and removing those metals will require an extra processing step. In addition, the ore’s complex chemistry requires different approaches to managing brine. A multi

Potash Data Sheet Mineral Commodity Summaries 2020

The fertilizer industry used about 85% of U.S. potash sales, and the remainder was used for chemical and industrial applications. About 80% of the potash produced was SOPM and SOP, which are required to fertilize certain chloride-sensitive crops. Muriate of potash accounted for the remaining 20% of production and was used for agricultural and

ITP Mining: Energy and Environmental Profile of the U.S.

3.1 Process Overview 3.1.1 Mining Methods Potash Mining Conventional, solution, and cut-and-fill stope mining are methods used in extracting ore for potash. Potash (rock) The ore is dry-crushed by rod and ball mills to free the KCL (potassium chloride, or potash) and put into a brine similar to salt water.

Meeting the needs of an exacting market Eriez

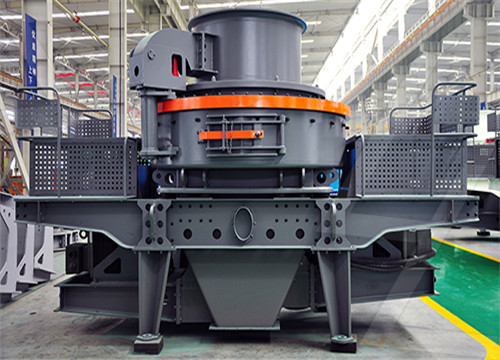

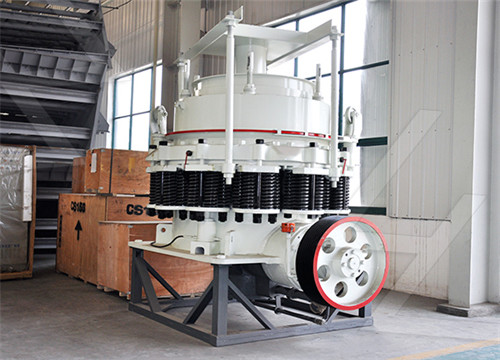

POTASH ORE PROCESSING Meeting the needs of an exacting market The production of marketable potash from the basic ore may comprise a series of processes, including crushing and pre-screening, milling, flotation, salt leaching from the flotation concentrate, drying, granulation and refining. Developments in potash processing technology are

Potash Processing in Saskatchewan CIM Bulletin

Liberation in the Esterhazy member ores is substantial at 9.5 mm, and for the Patience Lake member ores is 1.2 mm. Potash, like most industrial minerals, is sold based both on its chemical composition as well as its size distribution. Fertilizer grade potash is marketed with a chemical composition of 60% K 2O minimum. Various potash fertilizer

Processing of potash ore

The processing of potash ores by hot leaching with further crystallization of potash salt from saturated salt brines (halurgical method) began in XIX century in Strasburg. The primary methods of potash ore processing are flotation (mechanical method) and hot leaching (chemical method).

Potassium analyser for the potash industry Berthold

Potassium content measurement for the potash industry is one of the most difficult and challenging measurements in the mining industry. It is however essential in the potash production process. Potassium contains the radioactive isotope K-40. This isotope is only found in extremely small quantities in the ore itself.

Three geologists killed in Spanish potash mine collapse

1 Three geologists have been killed in a mine collapse in northern Spain. The incident occurred at Cabanasses de Súria mine just before 9am local time on Thursday. The mine is located in the town of Suria, around 80km north of Barcelona. It is operated by Iberpotash, a subsidiary of the Israel-based ICL group.

Optimizing potash processing using the OLI Software

2021年3月10日Potash ores are typically obtained by conventional shaft mining with the extracted ore ground into a powder. Other methods include dissolution mining and evaporation methods from brines. In the above-ground processing plants, KCl is separated from crude (rock) salt (mostly NaCl or MgCl2 or MgSO4.H2O (kieserite)) by thermal

Potash Production ArrMaz

The extracted potash ore is then milled the ore is crushed into small pieces to release potash and salt crystals, and agitated to separate the crystals from clay particles which are then removed using size separators. The next step in the process is flotation whereby flotation reagents are added to the mixture of potash, salt and brine.

Heavy Media Separation an overview ScienceDirect Topics

36.5. Other potash ore processing methodsA number of studies were carried out to examine beneficiation of potash ores using alternative methods. These include: In this process, lithium ores are concentrated with respect to lithium oxide from 1–3% Li 2 O to 4–6% Li 2 O through heavy medium separation using dense nonaqueous liquids in a

[PDF] Potash processing in Saskatchewan: a review of process

Potash processing in Saskatchewan: a review of process technologies. C. F. Perucca. Published 2003. Geology. Cim Bulletin. Potassium is one of the three basic plant nutrients along with nitrogen and phosphorus. There is no substitute for potassium compounds in agriculture; they are essential to maintain and expand production.

Potash: Deposits, Processing, Properties and Uses SpringerLink

Sylvinite, Other Potash Ore Processing. Donald E. Garrett; Pages 325-402. Brine Processing Operations. Donald E. Garrett; Pages 403-439. Non-Chloride Products. Donald E. Garrett; sulfate of potash, etc. When referring to ores, or in geology, all of the naturally found potassium salts are called "potash ores". However, originally potash

Engineering designs for potash processing facility

2022年12月31日Processing the potash, however, will require a change from commonly used methods. Ore in the Khemisset basin contains iron and magnesium, and removing those metals requires an extra processing step. In addition, the ore’s complex chemistry requires different approaches to managing brine.

Potash Ore Market Designing Africa's First Potash Processing

2022年12月13日Processing that potash, however, will require a change from commonly used methods due to its mineral content. Ore in the Khemisset basin contains iron and magnesium, and removing those metals will require an extra processing step. In addition, the ore’s complex chemistry requires different approaches to managing brine. A multi

Heavy Media Separation an overview ScienceDirect Topics

Some of the processes include: • Attrition scrubbing washing • Magnetic separation • Heavy media separation • Reverse gangue flotation • Acid leaching A combination of the above methods may be used to beneficiate sand with complete impurities. For many applications, clean sand to over 99% silica with low impurities is required.

Optimizing potash processing using the OLI Software

2021年3月10日Potash ores are typically obtained by conventional shaft mining with the extracted ore ground into a powder. Other methods include dissolution mining and evaporation methods from brines. In the above-ground processing plants, KCl is separated from crude (rock) salt (mostly NaCl or MgCl2 or MgSO4.H2O (kieserite)) by thermal

Meeting the needs of an exacting market Eriez

POTASH ORE PROCESSING Meeting the needs of an exacting market The production of marketable potash from the basic ore may comprise a series of processes, including crushing and pre-screening, milling, flotation, salt leaching from the flotation concentrate, drying, granulation and refining. Developments in potash processing technology are

Potash Processing in Saskatchewan CIM Bulletin

Liberation in the Esterhazy member ores is substantial at 9.5 mm, and for the Patience Lake member ores is 1.2 mm. Potash, like most industrial minerals, is sold based both on its chemical composition as well as its size distribution. Fertilizer grade potash is marketed with a chemical composition of 60% K 2O minimum. Various potash fertilizer

[PDF] Potash processing in Saskatchewan: a review of process

Potash processing in Saskatchewan: a review of process technologies. C. F. Perucca. Published 2003. Geology. Cim Bulletin. Potassium is one of the three basic plant nutrients along with nitrogen and phosphorus. There is no substitute for potassium compounds in agriculture; they are essential to maintain and expand production.

Potassium analyser for the potash industry Berthold

Potassium content measurement for the potash industry is one of the most difficult and challenging measurements in the mining industry. It is however essential in the potash production process. Potassium contains the radioactive isotope K-40. This isotope is only found in extremely small quantities in the ore itself.

Three geologists killed in Spanish potash mine collapse

1 Three geologists have been killed in a mine collapse in northern Spain. The incident occurred at Cabanasses de Súria mine just before 9am local time on Thursday. The mine is located in the town of Suria, around 80km north of Barcelona. It is operated by Iberpotash, a subsidiary of the Israel-based ICL group.

Intensification of the flotation separation of potash ore using

2021年9月1日Potash ores are a mixture of sylvite (KCl), halite (NaCl), and other complex double salts, such as carnallite Microwave pre-treatment can be used to convert the serpentine gangue to olivine, which should improve ore processing. However, the fundamental microwave properties and heating behaviour of ultramafic ores must be

Mechanical Properties and Mineralogical Composition of Potash Ore

2021年2月1日The correct selection of technology for processing potash ore depends on its mineralogical composition, the natural size and shape of grains, as well as on the amount and size of halite grains

(PDF) Investigation of the Destruction Process of Potash Ore

2021年1月5日Potash ore cutting with a single cutter is a complex multifactorial cycle process of alternation of phases of contact crushing and the formation of large cleavages. The sep-

Sustainable Process for the Extraction of Potassium from Feldspar

2020年6月16日The order of the roasting process was found to be 2.158 and activation energy calculated to be 155.3 kJ/mol. Apart from potassium, sodium and excess calcium also got co-leached. To recover potassium from the leach liquor selectively, sodium perchlorate was added to precipitate potassium as KClO 4.