Mining Mill Machine For Sinter

CEREC Dental Milling Machines Dentsply Sirona USA

The CEREC grinding and milling machines are equipped with a device to vacuum up the mill shavings. They can be used for both wet and dry processing, one straight after the

进一步探索

CEREC Machine Cost 2018 (Is A CEREC Machine Worth It?)CEREC MC XL milling units and burs Dental CAD CAM ShopThe Best Dental milling machines for 2022 Most People's What Is A Cerec Machine And What Are The Benefits?Top 5 Milling Machines In The Dental Industry根据热度为您推荐•反馈

CEREC MC X: Dental Milling Machine Dentsply Sirona USA

Advantages of CEREC MC X. Precise and fast, approximately 11 minutes for a crown, depending on material, design and process. Entire range of chairside treatment with up

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019年6月11日According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw materials, including iron

Sinter plant Wikipedia

Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux (limestone) fines. In addition to base mix, coke fines, flux fines, sinter fines, iron dust (collected from plant de-dusting systemESP) and plant waste are mixed in proportion (by weight) in a rotary drum, often called mixing and nodulizing drum. Calcined lime is used as binder of the mixed material al

Raw materials Sinter plant ArcelorMittal

Sinter is made by burning a mix of iron ore powder, fluxes and recycled substances from the steel plant to create an open-grained, consistent substance. The sinter is then crushed,

The Relationship Between Mining and Sintering

2019年8月15日The sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast

The Sintering Process of Iron Ore Fines IspatGuru

2013年3月9日Straight line machines are normally used for high capacity sinter plants. The sintering areas of such machines are generally 50 sqm and above. Present straight line machines are installed having widths

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size

Ceramill Therm DRS Amann Girrbach AG

5-axis milling and grinding unit, dry and wet processing. Ceramill Motion DRS. cera mill® motion drs. High-speed sintering so fast, so beautiful, so safe as well as

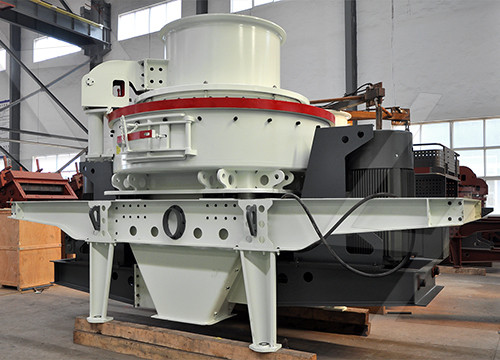

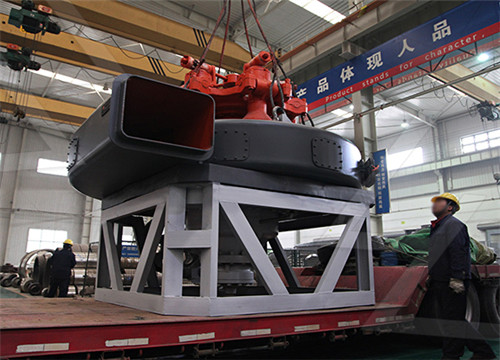

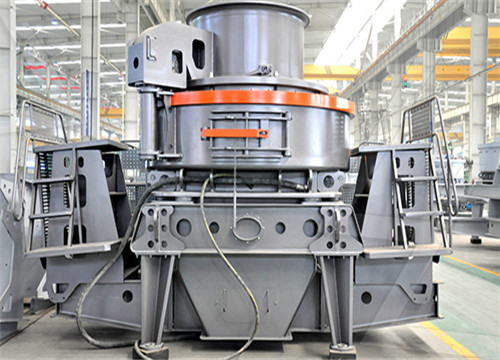

Zhengzhou Mega Industry Co., Ltd. mining machinery,ball mill

Zhengzhou Mega Industry Co., Ltd., Experts in Manufacturing and Exporting mining machinery,ball mill and 0 more Products. A Verified CN Gold Supplier on Alibaba.

CEREC MC X: Dental Milling Machine Dentsply Sirona USA

Advantages of CEREC MC X. Precise and fast, approximately 11 minutes for a crown, depending on material, design and process. Entire range of chairside treatment with up to 55 mm block size with small 6mm holder (from software 5.1.3) including bridges and abutments. Implant surgery with cost-effective surgical guides by Dentsply Sirona. 2 motors.

Raw materials Sinter plant ArcelorMittal

Sinter is made by burning a mix of iron ore powder, fluxes and recycled substances from the steel plant to create an open-grained, consistent substance. The sinter is then crushed, cooled and screened for dust. Sometimes, iron ore is supplied in the form of iron ore pellets.

How a Steel Plant Used Sinter Feed Analysis to Get

2020年9月15日T he U.S. Environmental Protection Agency explains that the sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated

The Relationship Between Mining and Sintering

2019年8月15日The Relationship Between Mining and Sintering. Sinter is the primary feed material for making iron in a blast furnace, and we have previously written about sintering and how it is a step between mining

Ceramill Therm DRS Amann Girrbach AG

5-axis milling and grinding unit, dry and wet processing. Ceramill Motion DRS. cera mill® motion drs. High-speed sintering so fast, so beautiful, so safe as well as combining the most important process steps in the fabrication of zirconia restorations in a single machine. The High-Speed Zirconia Kit offers every user an efficient

Manganese Ore Processing Mineral Processing

2016年4月27日The tailings from the Harz Jig are ground in a Steel Head Rod Mill after being dewatered by means of a Crossflow Classifier. The rod grate type mill, equipped with a 10 mesh spiral screen, grinds the jig

Zhengzhou Mega Industry Co., Ltd. mining machinery,ball mill

mining machinery,ball mill,cement production line,jaw crusher,act Mid East, Central America, Western Europe, Southeast Asia, Easter Learn more about us Main Categories > Production Lines Coal Washing Plant with capacity 200,000-3,000,000TPY Coal jigging machine, jigger, jig 300TPD professional Cement factory

CEREC Speedfire Dentsply Sirona USA

CEREC SpeedFire is the smallest and fastest sintering furnace on the market and can typically sinter a crown in approximately 14 minutes 1. The advantages of full-contour zirconia can thus also be used for chairside treatment. CEREC SpeedFire can process the Dentsply Sirona ceramic block materials as well as partner materials from Ivoclar, VITA

Hybrid Metal Laser SinteringMilling Machine YouTube

2017年3月21日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

hyperDENT FOLLOW-ME! Technology Group

Loads the milling program directly onto the machine and is activated in hyperDENT® (dependent on milling machine). x. x. Engraving. Engraves parts for identification. x. x. Blank milling. Mills all types of blanks and

Ball Mill RETSCH powerful grinding and homogenization

The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. CoolingHeating Mixer Mill MM 500 control Material feed size*: <= 10 mm Final fineness*: ~ 0.1 µm Vibrational frequency: 3 30 Hz (180 -1800 min-1) Product details Nanoscale Grinding

Gold Processing Plant Prominer (Shanghai) Mining Technology

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and

mining mill machine for sinter

Mining > Crusher Mill > sinter and pellet making in jsw Print sinter and pellet making in jsw Posted at:June 2, 2013[ 4.9 2049 Ratings] Chapter 4: Agglomeration. Indian Bureau of Mines mix of sinter, pellets and lumps would govern the future scenario.

mill/sbm parts of sinter crusher ussr.md at master mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long. 1 Commit. 1 Branch. 0 Tags mill / sbm parts of sinter crusher...

CEREC MC X: Dental Milling Machine Dentsply Sirona USA

Advantages of CEREC MC X. Precise and fast, approximately 11 minutes for a crown, depending on material, design and process. Entire range of chairside treatment with up to 55 mm block size with small 6mm holder (from software 5.1.3) including bridges and abutments. Implant surgery with cost-effective surgical guides by Dentsply Sirona. 2 motors.

Raw materials Sinter plant ArcelorMittal

Sinter is made by burning a mix of iron ore powder, fluxes and recycled substances from the steel plant to create an open-grained, consistent substance. The sinter is then crushed, cooled and screened for dust. Sometimes, iron ore is supplied in the form of iron ore pellets.

How a Steel Plant Used Sinter Feed Analysis to Get

2020年9月15日T he U.S. Environmental Protection Agency explains that the sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated

Home Amann Girrbach AG

Intelligent 5-axis milling and grinding unit, wet and dry processing. Ceramill Motion 2. cera mill® motion 2. 5-axis milling and grinding unit, dry and wet processing. Sintering furnace for sinter metal. Ceramill Therm S.

The Relationship Between Mining and Sintering

2019年8月15日The sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast

MiningMineral Processing Equipment FEECO International Inc.

Equipment FEECO offers a variety of equipment to support the mining industry, including: Bulk Material Handling Belt feeder Belt conveyor Belt tripper Steep incline conveyor Stack out conveyor Bucket Elevators Agglomeration Pin Mixer Pug Mills Agglomeration Drums (Ore Agglomerators) Disc Pelletizers Thermal Processing Rotary Dryers Rotary Kilns

Manganese Ore Processing Mineral Processing

2016年4月27日The tailings from the Harz Jig are ground in a Steel Head Rod Mill after being dewatered by means of a Crossflow Classifier. The rod grate type mill, equipped with a 10 mesh spiral screen, grinds the jig

Zhengzhou Mega Industry Co., Ltd. mining machinery,ball mill

mining machinery,ball mill,cement production line,jaw crusher,act Mid East, Central America, Western Europe, Southeast Asia, Easter Learn more about us Main Categories > Production Lines Coal Washing Plant with capacity 200,000-3,000,000TPY Coal jigging machine, jigger, jig 300TPD professional Cement factory

CEREC Speedfire Dentsply Sirona USA

CEREC SpeedFire is the smallest and fastest sintering furnace on the market and can typically sinter a crown in approximately 14 minutes 1. The advantages of full-contour zirconia can thus also be used for chairside treatment. CEREC SpeedFire can process the Dentsply Sirona ceramic block materials as well as partner materials from Ivoclar, VITA

Hybrid Metal Laser SinteringMilling Machine YouTube

2017年3月21日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

hyperDENT FOLLOW-ME! Technology Group

Loads the milling program directly onto the machine and is activated in hyperDENT® (dependent on milling machine). x. x. Engraving. Engraves parts for identification. x. x. Blank milling. Mills all types of blanks and

(PDF) Bed Permeability State Prediction Model of Sintering

2016年12月15日The bed permeability state prediction model of sintering process based on data mining technology was proposed in this study. Firstly, the sintering production data were analyzed by fuzzy

mining mill machine for sinter

Mining > Crusher Mill > sinter and pellet making in jsw Print sinter and pellet making in jsw Posted at:June 2, 2013[ 4.9 2049 Ratings] Chapter 4: Agglomeration. Indian Bureau of Mines mix of sinter, pellets and lumps would govern the future scenario.

Gold Processing Plant Prominer (Shanghai) Mining Technology

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and