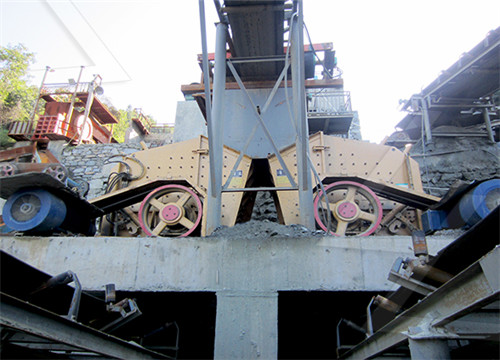

Single Toggle Jaw Crusher Applied In Grinding Lines

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

根据热度为您推荐•反馈

High-performance crushing with TST Jaw Crusher

根据热度为您推荐•反馈

Laboratory and pilot plant Primary Jaw Crushers

High productivity: these machines are capable of fast and efficient crushing; Simple operation: designed with a mechanically simple single toggle, the jaw crushers are reliable and easy to maintain and repair.; Safe to

Different types of crushers for distinctive needs Metso

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher.

Laboratory Jaw Crusher 911Metallurgist

A jaw crusher robustly constructed single-toggle type with one fixed jaw plate and one moving jaw plate. Designed for the smaller laboratory, or use by prospectors. It is capable of quickly crushing materials up to 85% of

(PDF) Analysis of the Single Toggle Jaw Crusher

2015年4月1日Show abstract. Oduori et al. [19] analysed the kinematics of the single toggle jaw crusher, as modelled in Figure 1, and found the following expression: Cao et al. [20] used the dimensional

Difference Between SingleDouble Toggle Jaw Crusher

2014年9月20日Double Toggle Jaw Crusher In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the

What Is a Jaw Crusher? Here's How It Works Cutting

2021年2月18日A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and

Jaw Crusher for Primary Crushing Fote Machinery

Jaw crusher, invented by Whitney Blake in 1858, is a primary stone crushing machine for reducing minerals or stones into smaller sizes. It is a must-have machine in wide range of fields like mining, quarrying, and

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

Laboratory and pilot plant Primary Jaw Crushers

High productivity: these machines are capable of fast and efficient crushing; Simple operation: designed with a mechanically simple single toggle, the jaw crushers are reliable and easy to maintain and repair.; Safe to

High-performance crushing with TST Jaw Crusher

Technical specifications and features of our TST Jaw Crushers include: Efficient crushing motion, modular frame and a simple, low maintenance design ; Single toggle jaw crusher ; Chamber design that enables the

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Different types of crushers for distinctive needs Metso Outotec

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates.

Study on Liner wear in Single Toggle Jaw Crushers: A Review

The Blake jaw crusher was originally designed by Eli Whit-ney Blake in 1857 [3]. The Blake jaw crushers are of two types: double toggle Blake and single toggle Blake as shown in Fig-ure 2. The double toggle machine, though robust and power consuming, can crush very hard rocks without abrasive wear.

What Is a Jaw Crusher? Here's How It Works

2021年2月18日A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and

Characteristics and Comparison of Four Types of Jaw

2023年2月15日Single toggle jaw crusher An eccentric shaft is positioned on the top of the crusher. The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which

Single Toggle Jaw Crusher Premur Impex No.1 Crushers

Application. Primary and Secondary Crushing of Hard rocks, ores and Minerals including Lime Stone, Dolomite, Granite, Iron Ore, Chromite Ore, Ferro-alloy slag etc., with a normal Crushing ratio of 6:1. The crushing action take place by impact of

Single Toggle Jaw Crusher Manufacturer Exporter Supplier

Single Toggle Jaw crushers are used for primary crushing. Single Toggle Jaw Crusher is designed for exceptionally heavy and continuous applications. Single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of high-grade

A fundamental model of an industrial-scale jaw

2017年5月1日The gangue crushing equipment used in the experiment is a jaw crusher which is also traditional ore-crushing equipment commonly used in mines. Due to its simple structure and reliable...

single toggle jaw crusher 英中 Linguee词典

大量翻译例句关于"single toggle jaw crusher" 英中词典以及8百万条中文译文例句搜索。 single toggle jaw crusher 英中 Linguee词典 在Linguee网站寻找

TST jaw crusher Dorr-Oliver Eimco DirectIndustry

These crushers have continuously withstood the harshest duties found in the world. With constant and continual improvements to the designs, the TDT has been solidified as a preferred crusher throughout the industry. is proud to add their new line of single toggle jaw crushers, the TST, to the heritage the double toggle crushers

Static Materials Processing Technology Corporation

protection and reset, ® TC Cone Crushers provide excellent reduction and product cubicity for the production of high-grade aggregate and sub-base materials. Plus, our simple wear part change design keeps downtime to a minimum. Cone Crushers Jaques ST Series Durable. Dependable. Adaptable. Our Jaques Single Toggle jaw crushers feature

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

High-performance crushing with TST Jaw Crusher

Technical specifications and features of our TST Jaw Crushers include: Efficient crushing motion, modular frame and a simple, low maintenance design ; Single toggle jaw crusher ; Chamber design that enables the

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Fine Jaw Crushers

Unlike ordinary toggle jaw crushers. Our JC2501 uses an oscillating motion to rapidly reduce near jaw size lumps to 2 mm in a single step. Its other highly valued features include easy and precise jaw gap adjustment to give you excellent control of product sizing. It also has roller bearings for reliability at high load capability.

Analysis of the Single Toggle Jaw Crusher Force

2016年12月7日The force transmission characteristics can be used as criteria for the comparison of different jaw crusher mechanism designs in order to select the most suitable design for a given application

A fundamental model of an industrial-scale jaw

2017年5月1日The gangue crushing equipment used in the experiment is a jaw crusher which is also traditional ore-crushing equipment commonly used in mines. Due to its simple structure and reliable...

Different types of crushers for distinctive needs Metso Outotec

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates.

What Is a Jaw Crusher? Here's How It Works

2021年2月18日A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and

Study on Liner wear in Single Toggle Jaw Crushers: A Review

The Blake jaw crusher was originally designed by Eli Whit-ney Blake in 1857 [3]. The Blake jaw crushers are of two types: double toggle Blake and single toggle Blake as shown in Fig-ure 2. The double toggle machine, though robust and power consuming, can crush very hard rocks without abrasive wear.

Used single toggle jaw crushers Machinio

2020 Tesab 700i. USED. Manufacturer: Tesab. Model: 700I. -28 in. X 44 in. single toggle jaw -Remote control -Twin feeder w/ vibrating grizzly feeder -CAT C7.1 tier 4 engine -Magnet and dust suppression Please call with any questions, (410) 216-3949, Se Habla Español. $291,750 USD.

Single Toggle Jaw Crusher Premur Impex No.1 Crushers

Application. Primary and Secondary Crushing of Hard rocks, ores and Minerals including Lime Stone, Dolomite, Granite, Iron Ore, Chromite Ore, Ferro-alloy slag etc., with a normal Crushing ratio of 6:1. The crushing action take place by impact of

Single Toggle Jaw Crusher Manufacturer Exporter Supplier

Single Toggle Jaw crushers are used for primary crushing. Single Toggle Jaw Crusher is designed for exceptionally heavy and continuous applications. Single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of high-grade

TST jaw crusher Dorr-Oliver Eimco DirectIndustry

An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic design. The chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout.

Static Materials Processing Technology Corporation

Our Jaques Single Toggle jaw crushers feature large gape feed openings, and combine high production capacity and low operating costs. Built to withstand the rigors of working in ores, rock gravel and recycled concrete, they are manufactured with durable, heavy-duty components for consistent performance and long life.