Secondary Standard Crushing Equipment

Downstream Crushing Options for Secondary, Tertiary and

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances downward thro在mclanahan上查看更多信息What is secondary crushing?查看关于此结果的此主题和其他主题

Types of Crushers: What You Need to Know Machinery Partner

The main kinds of crushing machines for secondary processing are discussed below. Cone crushers Cone crushers are one of the main choices for secondary crushing. A

进一步探索

5 Types Of Stone Crushers Application and MaintenanceUnderstanding the Different Types of Crushers Agg-Net根据热度为您推荐•反馈

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers,

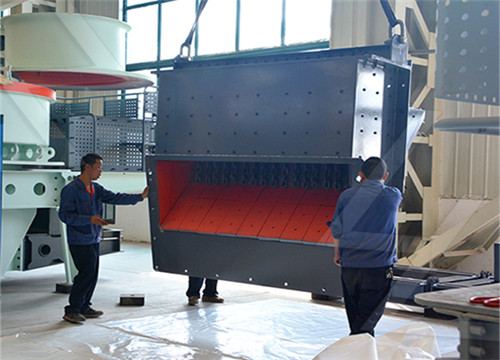

Secondary Crushing Equipment Mineral Processing

2016年2月28日The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone

Crushing Metso Outotec

Metso Outotec in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC

Secondary Impact Crushers StoneGranite Crushing

The Stedman Grand-Slam secondary impact crushers are built to handle thousands of materials, ores, and chemicals in wet and dry applications. The crushing action of the

Different types of crushing equipments Constro Facilitator

2020年5月6日A secondary crusher comes into action and further reduces the size. In secondary crushers some sizes of stones may pass directly from sieve number At the

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日Open Circuit Crushing. In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating

CS430 Cone Crusher For Secondary Crushing Applications

This crusher is suitable for a high-capacity secondary crushing application. CS430 cone crusher is characterized by the large intake capability and the high capacity in relation to size, proving to be a versatile and efficient option for many applications. The Automatic Setting Regulation control system (ASRi™) enables real-time

Cone Crusher an overview ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers.

Types of Rock Crushers Quarry Crushing Equipment

Here at Kemper Equipment, we offer the best performing crushing equipment that will work hard to make any finished products you plan to produce—including sand, gravel, fertilizer, specialty mineral products,

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone

Crushing Metso Outotec

The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations. The Foresight™ Stations are focused on smart controls and automation for optimal productivity.

Secondary Impact Crushers StoneGranite Crushing Equipment

The Stedman Grand-Slam secondary impact crushers are built to handle thousands of materials, ores, and chemicals in wet and dry applications. The crushing action of the Grand-Slam HSI delivers properly sized material the first time through. The field-proven, Stedman Grand Slam secondary impact crushers will give you years of dependable and

Symons Cone Crusher 911Metallurgist

For finer crushing or reduction a Symons cone crusher the norm. Symons are commonly used for secondary, tertiary or quaternary crushing. They do this by a different chamber design which is flatter and by operating at

Crushers and Their Types IspatGuru

2015年4月3日Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and tertiary crushing circuit there are three main types of machinery,

Cone Crusher For Sale Secondary Crushing Equipment

1. Single-cylinder type is suitable for secondary crushing, multi-cylinder is suitable for fine crushing. 2. If you need more aggregate than fine, you can choose a single cone crusher plant. 3. It is recommended to use a multi-cylinder

Two vs three-stage crushing Australian Mining

Three-stage crushing system: Feeder breaker, secondary sizer, screen and tertiary sizer The three-stage crushing system will be more expensive to purchase than a two-stage system. However, it results in a better quality of coal because the

Equipment Mellott

Looking for rock crushing equipment for your aggregate production or construction needs? Contact the professionals at Mellott to learn more. Contact. Email Form. Support. 855.554.1606. Sales. while a secondary gyratory crusher is used to further reduce the size of rock particles.

Premier Equipment CS440 Cone Crusher

CS440 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary crushing application. This equipment is designed to be easy to maintain and service, allowing

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In secondary stages, a standard-head cone is usually specified. A short-head cone is typically used in tertiary and quaternary stages. Cone crushers can crush stone of medium to very hard compressive strength as well as abrasive stone. VERTICAL-SHAFT IMPACT CRUSHER Photo by Kevin Yanik

CS430 Cone Crusher For Secondary Crushing Applications

This crusher is suitable for a high-capacity secondary crushing application. CS430 cone crusher is characterized by the large intake capability and the high capacity in relation to size, proving to be a versatile and efficient option for many applications. The Automatic Setting Regulation control system (ASRi™) enables real-time

Types of Rock Crushers Quarry Crushing Equipment

Here at Kemper Equipment, we offer the best performing crushing equipment that will work hard to make any finished products you plan to produce—including sand, gravel, fertilizer, specialty mineral products,

Crushing Metso Outotec

The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations. The Foresight™ Stations are focused on smart controls and automation for optimal productivity.

Secondary Impact Crushers StoneGranite Crushing Equipment

The Stedman Grand-Slam secondary impact crushers are built to handle thousands of materials, ores, and chemicals in wet and dry applications. The crushing action of the Grand-Slam HSI delivers properly sized material the first time through.

Symons Cone Crusher 911Metallurgist

Studies have shown that converting the second stage gyratory crusher to a 10 Ft. Standard crusher shows most potential because the major auxiliaries required for the crusher, such as crane, conveyors, etc., are

New and used Crushers for sale Ritchie Bros.

Search our inventory to find jaw crushers, impact crushers, cone crushers, cone crushing plants, jaw crushing plants, roll crushers, roll crushing plants, and hammermills. More crushers added daily from manufacturers

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and tertiary crushing circuit there are three main types of machinery,

Equipment Mellott

Looking for rock crushing equipment for your aggregate production or construction needs? Contact the professionals at Mellott to learn more. Contact. Email Form. Support. 855.554.1606. Sales. while a

Cone Crusher For Sale Secondary Crushing Equipment

1. Single-cylinder type is suitable for secondary crushing, multi-cylinder is suitable for fine crushing. 2. If you need more aggregate than fine, you can choose a single cone crusher plant. 3. It is recommended to use a multi-cylinder

30 CFR Part 56 -- Safety and Health Standards eCFR :: Home

This part 56 sets forth mandatory safety and health standards for each surface metal or nonmetal mine, including open pit mines, subject to the Federal Mine Safety and Health Act of 1977. The purpose of these standards is the protection of life, the promotion of health and safety, and the prevention of accidents.

Hydraulic Cone Crusher AF Minerals Equipment

Several standard crushing chambers are available for each model. The crushers can easily be matched to changes in production through the proper selection of crushing chamber and eccentric throw. AF cone crushers are an excellent choice as secondary crushers in combination with a jaw or primary gyratory crusher or in the third or fourth crushing

Premier Equipment CS440 Cone Crusher

CS440 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary crushing application. This equipment is designed to be easy to maintain and service, allowing

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not comprehensive.

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In secondary stages, a standard-head cone is usually specified. A short-head cone is typically used in tertiary and quaternary stages. Cone crushers can crush stone of medium to very hard compressive strength as well as abrasive stone. VERTICAL-SHAFT IMPACT CRUSHER Photo by Kevin Yanik