Grinding Plant Maintenance

Mill maintenance 3 simple ways to keep your mill at its

keep your mill clean. This may sound obvious but a fundamental part of mill

Cement plant maintenance: 6 tips to reduce baghouse energy cost

Monitoring your dust collector. To avoid unplanned downtime, it is highly

Aerospace Industrial Maintenance Services ATS

Maintain reliability as demand soars. In light of the growth in demand for high-tech civilian, military and space equipment, the aerospace industry requires consistent reliability and

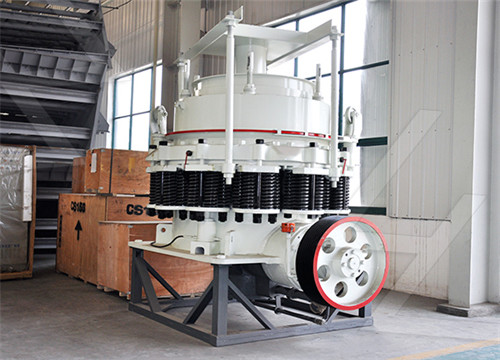

Grinding Maintenance Crusher Mills, Cone Crusher, Jaw Crushers

Grinding: Your #1 Source for CNC Grinding Solutions . Preventative Maintenance service is now available! Keep your machine in top conditionschedule PM today!

MAINTENANCE IN THE CEMENT INDUSTRY

Many companies have tried to use standard production methods to control maintenance cost. This is not effective. The maintenance can increase

Hazards during maintenance Safe maintenance HSE

Undertaking maintenance activities can potentially expose the workers involved (and others) to all sorts of hazards, but there are four issues that merit particular attention

Turnkey Project Solutions and Turnkey Plant Solutions

Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. KNOW MORE. Dynamic. Separators. Dynamic Separators. Plant Audit and Maintenance

Maize Milling Plant Ordinary Maintenance Corn Grinding Machine

2014年9月9日Therefore, maize milling plant ordinary maintenance is necessary! Maize milling plant ordinary maintenance content: 1. Key machines maintenance; 2. Maize

Cement Grinding Unit Cement Grinding Plant

The cement grinding unit has the advantages of simple structure, strong controllability, and easy to operate or maintain. The discharge concentration is less than 50mg/Nm3, lower than the discharge standard, and protect

Companies Fouad AlghanimSons Group of

Major supplier of high quality aggregates, specialized sand and gravel products to Kuwait’s construction industry. Own production plants in Kuwait. Supply a wide range of aggregates in varying sizes and

Training seminars and courses Institute

You can participate in our training courses online, on-site, or at one of our facilities throughout the world. Our highly skilled specialists offer unique, hands-on training designed to improve your knowledge and plant productivity, from general equipment maintenance and operations through process controls and system optimisation.

Cement plant maintenance: 6 tips to reduce

Here you can read 6 recommendations that are to be considered for your maintenance. 1. Monitoring your dust collector To avoid unplanned downtime, it is highly important to strictly monitor the effectivity of the Kiln

Grinding in Ball Mills: Modeling and Process

2012年6月1日The central purpose of grinding models is to obtain mathematical relationships between the size of the feed and the size of the product (Monov et al., 2012). Size reduction is a result of three...

Cement mills and raw mills for small to medium throughput rates

The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills. Optimum utilization of process heat The thermal energy of process gases can be used on MVR mills. Highest availability

Modular grinding plant Mill system ready2grind

Grinding on the ready2grind system. The ready2grind system is extraordinarily compact. The modules in standard container sizes are delivered preassembled. The grinding process is the same as that of

Aerospace Industrial Maintenance Services ATS

Maintain reliability as demand soars. In light of the growth in demand for high-tech civilian, military and space equipment, the aerospace industry requires consistent reliability and uptime to meet its lofty production goals. ATS can help you overcome the challenges preventing you from achieving optimal productivity.

(PDF) Preventive Maintenance Checklist towards

2013年8月1日PDF Preventive maintenance (PM) is the basic policy in maintenance system and widely used in companies all over the world. manufacturing plant [1]. Maintenance is considered a non-value

HPGR High Pressure Grinding Rolls Mineral

2016年7月13日Use of HPGR eliminates tertiary crushing in a conventional grinding plant. In some cases, it may even eliminate the need for a secondary crushing stage. As an energy-saving alternative to the SAG

Turnkey Project Solutions and Turnkey Plant Solutions

Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. KNOW MORE. Dynamic. Separators. Dynamic Separators. Plant Audit and Maintenance

Hoehn Plastics Inc hiring Grinding Operator in Poseyville, Indiana

Job Description Grinding Operator This job position is a full-time employment or temp to hire position on a fixed shift work schedule. 1.0 Start up, set up, operate, and tend to the grinding and

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Land cement grinding. The cement grinding and drying system be dovetail of a large array of obsolete incompetent equipment and was completely replaced by a single VRM, it improves the fineness and diminish the maintenance and power consumption [1, 34, 36]. Optimization of cement grinding using standard bond grinding calculations based

Analysis of garden plant configuration and maintenance

With the rapid development of society and economy, people's cultural levels is improving, and the demand for green space is increasing year by year. The construction of gardens and green spaces has become an important way to improve the quality of life. As a crucial part of landscaping, garden plant configuration and maintenance have been paid more and

NAICS Code: 561730 Landscaping Services NAICS Association

This industry comprises (1) establishments primarily engaged in providing landscape care and maintenance services and/or installing trees, shrubs, plants, lawns, or gardens and (2) establishments primarily engaged in providing these services along with the design of landscape plans and/or the construction (i.e., installation) of walkways, retaining walls,

Spice Processing Plant RIECO Industries

Grinding: Chilli being heat sensitive are meticulously grounded in 3 stages 1st Stage: Cleaned chillies are cut into flakes or pizza cut size in Hammer Mill. They are separated in High efficiency cyclone. They can be taken out as end product or grounded further. 2nd Stage: Chilli flakes are grounded to coarse powder

Training seminars and courses Institute

You can participate in our training courses online, on-site, or at one of our facilities throughout the world. Our highly skilled specialists offer unique, hands-on training designed to improve your knowledge and plant productivity, from general equipment maintenance and operations through process controls and system optimisation.

Cement mills and raw mills for small to medium throughput rates

The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills. Optimum utilization of process heat The thermal energy of process gases can be used on MVR mills. Highest availability

Aerospace Industrial Maintenance Services ATS

Maintain reliability as demand soars. In light of the growth in demand for high-tech civilian, military and space equipment, the aerospace industry requires consistent reliability and uptime to meet its lofty production goals. ATS can help you overcome the challenges preventing you from achieving optimal productivity.

Modular grinding plant Mill system ready2grind

Grinding on the ready2grind system. The ready2grind system is extraordinarily compact. The modules in standard container sizes are delivered preassembled. The grinding process is the same as that of

Hot works procedure: Here's what's required

You hot works permit format should include: Basic record keeping information The issue and expiry data, instruction for permit applicants and a description or the type of hot works being performed. Hot works safety

Hazards during maintenance Safe maintenance HSE

Undertaking maintenance activities can potentially expose the workers involved (and others) to all sorts of hazards, but there are four issues that merit particular attention because of the severity of the harm that could be involved, and because they are commonly encountered during plant and building maintenance. Disturbing asbestos.

(PDF) Preventive Maintenance Checklist towards

2013年8月1日PDF Preventive maintenance (PM) is the basic policy in maintenance system and widely used in companies all over the world. manufacturing plant [1]. Maintenance is considered a non-value

Turnkey Project Solutions and Turnkey Plant Solutions

Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. KNOW MORE. Dynamic. Separators. Dynamic Separators. Plant Audit and Maintenance

Wastewater Treatment Plant Operations and Maintenance

Wastewater Treatment Plant Operations and Maintenance Manual Checklist for New Plants or Upgrades Directions for the Preparation of T reatment Plant O&M Manuals Any upgrades or new facility construction require that an Operation and Maintenance Manual be provided as part Sludge grinding mechanisms

NAICS Code: 561730 Landscaping Services NAICS Association

This industry comprises (1) establishments primarily engaged in providing landscape care and maintenance services and/or installing trees, shrubs, plants, lawns, or gardens and (2) establishments primarily engaged in providing these services along with the design of landscape plans and/or the construction (i.e., installation) of walkways,

Companies Fouad AlghanimSons Group of

EPC&C services Enhanced Oil Recovery Coil Tubing and well stimulation Drilling and Work Over Services Soil remediation Plant maintenance services Industrial cleaning solution New technology exploration R&D

Mineral Processing Design and Operations ScienceDirect

Key Features. Outlines the theory and practice in the design of flow sheets and operation of an integrated mineral processing plant. Introduces the basic magnetism, electrostatic, conductivity, and dielectrophoresis properties of minerals and related separation techniques.

Spice Processing Plant RIECO Industries

Grinding: Chilli being heat sensitive are meticulously grounded in 3 stages 1st Stage: Cleaned chillies are cut into flakes or pizza cut size in Hammer Mill. They are separated in High efficiency cyclone. They can be taken out as end product or grounded further. 2nd Stage: Chilli flakes are grounded to coarse powder