Chrome Washing Spiral

Spiral Concentrator Multotec

Spiral concentrators manufactured by Multotec are used in coal, gold, iron ore, mineral sands, platinum and chrome processing for ore between 382 000 µm. Ultrafine chrome spiral (UX7) Coarse (-3 mm) particle spiral

Spiral Concentrators Washing Chrome Gravity Separation

Spiral Concentrators Washing Chrome (4 replies and 4 comments) terrence 6 years ago i am using spirals to recover chrome fines size (-1mm) to (+100microns) from ore. l have

Gravity Spiral Concentrator Working Principle

2016年3月26日Wash water is supplied from a small wash-water channel paralleling the main channel. The Humphreys Spiral has been

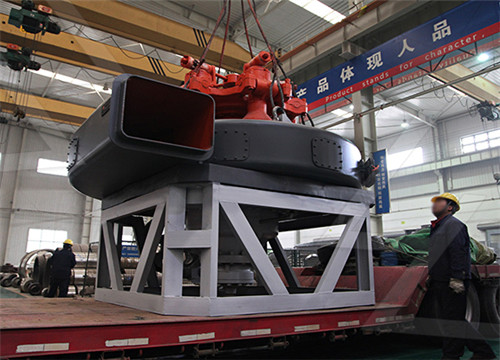

CHROME WASH PLANT Pineer Mining Machinery

The principle of chrome ore washing plant is to maximize the recovery rate of chrome and the associated heavy minerals from the Ganges firstly and then separate chrome ore from the associated heavy minerals by joint

chrome washing plant, chrome processing plant, chrome spiral

Chrome Processing Plant. Chrome is rare strategy resource in the world. With the development of mining amount, Chrome is to be exhausted as a non-renewable

chrome washing plant, chrome processing plant, chrome

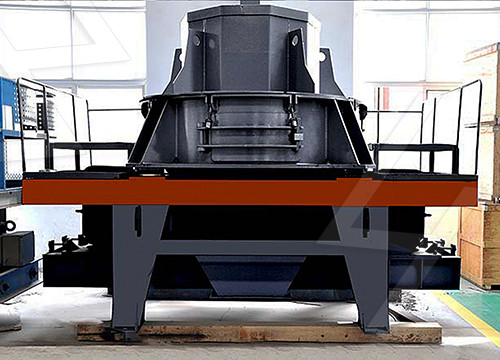

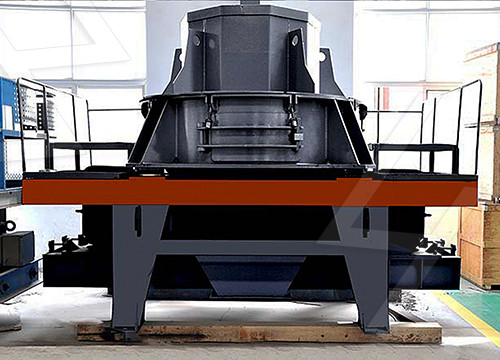

It uses spiral helix chute and shaking table as processing equipment, spiral helix chute as roughing equipment, and shaking table as concentrating equipment. Shaking table has a better effect on concentrating. Merits

Chrome Wash Plant, Chrome Spiral Wash Plant,

2.The smaller crushed chrome ore is fed to ball mill for grinding. Inside the ball mill, the crushed chrome ore will grind the ore to about 0.2 mm with 3-inch steel balls. 3. Screened products are transported to the jig for rough

How to clean chrome and remove rust and tarnish

2020年11月6日Apply a high quality chrome cleaner ( Cif PowerShine Bathroom or Cif PowerShine Kitchen are both good choices) to a clean cotton cloth, and wipe over the chrome. Leave as per the product’s

Chrome Industry Flow Sheet Multotec

Multotec's Chrome Industry Flow Sheet. We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

chrome washing plant, chrome processing plant,

It uses spiral helix chute and shaking table as processing equipment, spiral helix chute as roughing equipment, and shaking table as concentrating equipment. Shaking table has a better effect on concentrating. Merits

Spiral Concentrators Washing Chrome Gravity Separation

Spiral Concentrators Washing Chrome (4 replies and 4 comments) terrence 6 years ago i am using spirals to recover chrome fines size (-1mm) to (+100microns) from ore. l have noticed a high grade and reasonable amount of values in the tailings and after size analysis a majority of these fines are in the range of (-75microns).

New spiral chrome wash plant for chrome concentrate

chrome washing line Production Capacity: 98% Place of Origin: Shaanxi, China Brand Name: Desen Voltage: 220v/380v Dimension (L*W*H): 1560*1560*5230mm Weight: 0.8t, 0.04-0.8t Warranty: 2 Years Local Service Location: Philippines, Pakistan, Thailand, Kenya, Colombia Certification: ISO9001: 2008 CE BV SGS After-sales Service Provided:

Bauba awards chrome spiral circuit wash plant contract in South

2018年2月19日Bauba Platinum has awarded a contract for a chrome spiral circuit wash plant and the primary crushing circuit at its Moeijelijk mine in Limpopo province, South Africa. The R18.4m ($1.57m) contract was awarded to an undisclosed company and covers the plant’s design, construction, and commission. Scheduled to be commissioned by

chrome washing plant, chrome processing plant, chrome spiral wash

Chrome Processing Plant. Chrome is rare strategy resource in the world. With the development of mining amount, Chrome is to be exhausted as a non-renewable resource. The suitable mineral processing technology is required to increase the recovery rate.

sbm/sbm wanshuntong spiral chrome wash plant.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

lumpy chrome wash plant in South Africa --complete

Scope of Supply for lumpy chrome wash plant We can supply the whole line of lumpy chrome mining plant, including: 1. crushing machine, milling machine, ore feeder, etc 2. spiral chutes 3. hydrocyclones 4. slurry

How to clean chrome and remove rust and tarnish

2020年11月6日Wash the chrome Soak part of the sponge or cloth in your cleaning solution and apply it directly to the chrome, rubbing it in smooth, circular movements and removing as much surface dirt as possible.

Chrome Ore Beneficiation Process Chromite Processing JXSC

2019年5月15日Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator. 3 Experimental results and discussion 3.1 Chrome magnetic separation process The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering

Bauba’s chrome wash plant spot on African Mining

2019年3月12日JSE listed Bauba Platinum’s new wash plant at its Moeijelijk chrome mine in the Limpopo province of South Africa has been producing a spiral feed of about 35 000 tonnes per month (tpm) since

Chrome Washing Plant Spiral Concentrator in Jiangxi, China

Voltage: 380V, Weight: <1T, Material: Fiber Glass, Material feature: Corrosion Resistant, Certification: ISO9001:2008, SGS, Energy...

Chrome Washing Machine Xi'an Desen Mining Machinery

As roughing equipment, spiral chute can make the chrome ore grade increasing higher, but if want to get the better grade product, the final concentrator, shaking table is needed. Flow: Procedure: 1.The ore is first sent to the jaw crusher for primary crushing.

South Africa’s chrome sector, like its coal counterpart...

2021年3月7日It reveals at least 20 spiral or wash plants that are not located on any legitimate or regulated mine. The suspicions are that illicit ore is processed in some of these plants. The industry...

sbm/sbm chrome washing plant design.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

chrome washing plant, chrome processing plant,

It uses spiral helix chute and shaking table as processing equipment, spiral helix chute as roughing equipment, and shaking table as concentrating equipment. Shaking table has a better effect on concentrating. Merits

New spiral chrome wash plant for chrome concentrate

chrome washing line Production Capacity: 98% Place of Origin: Shaanxi, China Brand Name: Desen Voltage: 220v/380v Dimension (L*W*H): 1560*1560*5230mm Weight: 0.8t, 0.04-0.8t Warranty: 2 Years Local Service Location: Philippines, Pakistan, Thailand, Kenya, Colombia Certification: ISO9001: 2008 CE BV SGS After-sales Service Provided:

Bauba awards chrome spiral circuit wash plant contract in South

2018年2月19日Bauba Platinum has awarded a contract for a chrome spiral circuit wash plant and the primary crushing circuit at its Moeijelijk mine in Limpopo province, South Africa. The R18.4m ($1.57m) contract was awarded to an undisclosed company and covers the plant’s design, construction, and commission.

Spiral Concentrators Washing Chrome Gravity Separation

Spiral Concentrators Washing Chrome (4 replies and 4 comments) terrence 6 years ago i am using spirals to recover chrome fines size (-1mm) to (+100microns) from ore. l have noticed a high grade and reasonable amount of values in the tailings and after size analysis a majority of these fines are in the range of (-75microns).

chrome washing plant, chrome processing plant, chrome spiral wash

Chrome Processing Plant. Chrome is rare strategy resource in the world. With the development of mining amount, Chrome is to be exhausted as a non-renewable resource. The suitable mineral processing technology is required to increase the recovery rate.

Chrome Washing Plant Spiral Concentrator in Jiangxi, China

Voltage: 380V, Weight: <1T, Material: Fiber Glass, Material feature: Corrosion Resistant, Certification: ISO9001:2008, SGS, Energy...

sbm/sbm chrome washing plant design.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Find A Wholesale chrome ore spiral washing Online Alibaba

Make separation simple with a wholesale mineral separator. Alibaba is the place to look for chrome ore spiral washing tools, with options for ore extraction, precious metal mining and much more.

Bauba’s chrome wash plant spot on African Mining

2019年3月12日JSE listed Bauba Platinum’s new wash plant at its Moeijelijk chrome mine in the Limpopo province of South Africa has been producing a spiral feed of about 35 000 tonnes per month (tpm) since

Chrome Processing Plants North West Bond Equipment

We supply a range of plants for Chrome recovery. From pre-concentration of ROM ore, tailing's dump treatment and chrome wash-plants. Your business plan is dependent on the quality and efficiency of the chrome wash-plant. We understand this and build plants that are cost effective, however are robust and engineered to withstand the abrasive

Chrome Washing Machine Xi'an Desen Mining Machinery

As roughing equipment, spiral chute can make the chrome ore grade increasing higher, but if want to get the better grade product, the final concentrator, shaking table is needed. Flow: Procedure: 1.The ore is first sent to the jaw crusher for primary crushing.

Ad Categories Chrome Washing and Beneficiation Plants

R75 000. MAB014 40 Only Flat Bottom Spirals. Chrome Washing and Beneficiation Plants admin 07/04/2015. MAB014 40 Only Flat Bottom Spirals, Mineral Technologies HG 10F, as new, 760 mm diameter, 3 tph capacity, Vredendal area, R22 500 each, with 10% discount for a 1200 total views, 0 today.

Spiral Concentrator Jiangxi Hengchang Mining Machinery

China Spiral Concentrator catalog of Gold, Chrome, Coal, Tin Gravity Concentrator Separator Mineral Gravity Separator Spiral Chute Washing Plant, Gold Mining Equipment High Recovery Gravity Separator 1500 1200 Spiral Chute for Gold Mining Separation provided by China manufacturer Jiangxi Hengchang Mining Machinery Manufacturing

Spiral (Concentrators) an overview ScienceDirect Topics

The device has a wash water channel and a series of concentrate removal ports placed at regular intervals. The spiral concentrator first appeared as a production unit in 1943 in the form of the Humphrey Spiral, for the separation of chrome-bearing sands in Oregon. By the 1950’s, spirals were the standard primary wet gravity separation