Crushed Calcium Carbonate Size For Power Plant

Carbon mineralization pathways for carbon capture,

2021年2月26日CO 2 generated from power plants or industrial sources can be captured, Calcium carbonate is heated at 900–950 °C to

Ground Calcium Carbonate (GCC) Minerals

Specialty Minerals Inc. (SMI) manufactures crushed and ground limestone products at two of the Performance Minerals plants. At Adams, MA and Lucerne Valley, CA, high brightness limestone from adjacent SMI mines

Wet-limestone scrubber enhancement chemistry

2020年11月19日The limestone for the CWLP scrubbers contains greater than 95% calcium carbonate (CaCO 3) content. SO 2 in the flue gas first transfers to the liquid

Calcium carbonate Imerys

In paints and coatings, Imerys calcium carbonates are cost-effective multifunctional fillers that improve whiteness, opacity and matting. They make ideal replacements for titanium dioxide. In , Imerys

Facts about Soil Acidity and Lime (E1566) MSU Extension

2015年11月9日Calcium carbonate equivalent (CCE) refers to the equivalent amount (pounds) of pure calcium carbonate in a ton or cubic yard of lime material. If a lime material has a NV of 85, it will have a CCE

Agricultural lime Wikipedia

By combining the chemistry of a particular product (CCE) and its particle size the Effective Calcium Carbonate Equivalent (ECCE) is determined. The ECCE is percentage

Precipitated Calcium Carbonate Minerals Technologies Inc.

Mine high purity calcium carbonate rock. Crush the rocks to the particle size needed for processing small stones or powder. Separate some of the impurities from the crushed rock. Calcine (heat) in a kiln to 1850° F,

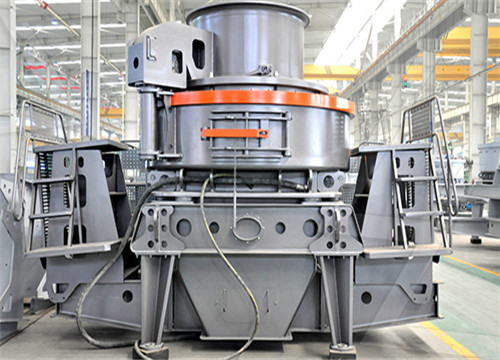

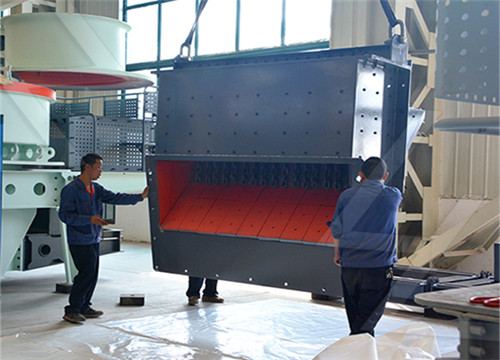

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

Ground Calcium Carbonate Manufacturing Process. Ground calcium carbonate is acquired by grinding raw materials such as limestone or marble. The whole ground

Limestone and Crushed Rock Energy

54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone. The average for the 20 plants was 33,500 Btu per ton. 1 Very few studies similar to the

Researchers: Power Plant Carbon-Capturing Calcium

2017年7月1日“In the first fluidized bed reactor, the absorber, a powder of burnt lime or calcium oxide (CaO), is contacted with the CO 2 in the power station exhaust to form calcium carbonate (CaCO 3).

(PDF) Techno-economic and Environmental Analysis of

2017年12月1日Techno-economic and Environmental Analysis of Calcium Carbonate Looping for CO 2 Capture from a Pulverised Coal-Fired Power Plant December 2017 Energy Procedia 142:3447-3453

Calcium carbonate Imerys

Calcium carbonate is one of the most abundant minerals on Earth and accounts for about 4% of the Earth’s crust. It can be found in nature in three principal rock types: chalk, limestone, and marble. Ground Calcium

Precipitated Calcium Carbonate Minerals

Mine high purity calcium carbonate rock. Crush the rocks to the particle size needed for processing small stones or powder. Separate some of the impurities from the crushed rock. Calcine (heat) in a kiln to 1850° F,

SCARLET Scale-up of Calcium Carbonate Looping

The calcium carbonate looping (CaL) process is a promising post-combustion technology for CO2 capture from fossil-fired power plants and carbon intense industries like steel and cement manufacturing.

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

Ground Calcium Carbonate Manufacturing Process. Ground calcium carbonate is acquired by grinding raw materials such as limestone or marble. The whole ground calcium carbonate production process consist of crushing, grinding and coating. After the raw material is quarried, the limestone or marble is crushed to smaller sizes.

Which liming material is best? Department of Primary Industries

Made from crushed magnesium carbonate rock, good quality magnesite has 25–28% magnesium, virtually no calcium, and NV of 95–105. Burnt magnesite (magnesium oxide) This is derived by heating magnesite, and contains about 50% magnesium. It is sold in granulated form and its NV is 180–220.

Crushed Calcium Vitamins for a Vegetable Garden

2017年9月21日A ratio of 68 to 12 is ideal. In all cases it's best to perform a soil test before adding supplements that might alter pH levels or the calcium/magnesium ratio. Note that blossom end rot may not indicate a lack of calcium in the soil at all, but instead an inability of the plant to transport calcium to its cells.

How to Add Calcium to Soil The Spruce

2021年6月29日Lime. (Calcium carbonate and other forms of mined limestone) Adding lime to your soil is the biggest calcium booster you can give your soil but it also raises your soil pH, making it less acidic. Garden

Garden Plot: Tums can help tomatoes, even when

2019年5月3日Then add calcium to prevent blossom end rot: a dozen crushed eggshells, a dozen crushed calcium carbonate tablets or a half- cup of a calcium-rich organic plant specifically...

Specialty Minerals Minerals Technologies Inc.

Talcs protect your car bumpers from damage and your house paints from weathering. Ground calcium carbonates (GCCs) make stuccos bright, roof shingles durable, and chewing gums chewy. PCCs and GCCs come

Calcium Carbonate (Limestone) Mosaic Crop Nutrition

Calcium carbonate, the chief component of limestone, is a widely used amendment to neutralize soil acidity and to supply calcium (Ca) for plant nutrition. The term “lime” can refer to several products, but for agricultural use it generally refers to ground limestone. Limestone of a smaller particle size reacts quickly because of the

Cement from CO 2 : A Concrete Cure for Global

2008年8月7日And attaching the Calera process to the nation's more than 600 coal-fired power plants or even steel mills and other industrial sources is even more attractive as burning coal results in flue gas

IJMS Free Full-Text Calcium-Based Antimicrobial Peptide

2022年9月26日Font Size: Aa Aa Aa. The shells for preparation of CAPCS were crushed and placed under vacuum conditions and 600 °C for 3 h, calcinated under mixed gas (40% air and 60% CO) and 1000 °C for 2 h, and then crushed with a micro nano pulverizer to obtain shell nano powders characterized with calcium carbonate porous

Researchers: Power Plant Carbon-Capturing Calcium

2017年7月1日Please contact [email protected] or call 888-707-5814 (M Th 9 am 5:30 pm and F 9 am 3 pm. ET),to start a free trial, get pricing information, order a reprint, or post an article link

(PDF) Techno-economic and Environmental Analysis of

2017年12月1日Techno-economic and Environmental Analysis of Calcium Carbonate Looping for CO 2 Capture from a Pulverised Coal-Fired Power Plant December 2017 Energy Procedia 142:3447-3453

SCARLET Scale-up of Calcium Carbonate Looping

The calcium carbonate looping (CaL) process is a promising post-combustion technology for CO2 capture from fossil-fired power plants and carbon intense industries like steel and cement manufacturing.

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

Ground Calcium Carbonate Manufacturing Process. Ground calcium carbonate is acquired by grinding raw materials such as limestone or marble. The whole ground calcium carbonate production process consist of crushing, grinding and coating. After the raw material is quarried, the limestone or marble is crushed to smaller sizes.

Which liming material is best? Department of Primary Industries

Made from crushed magnesium carbonate rock, good quality magnesite has 25–28% magnesium, virtually no calcium, and NV of 95–105. Burnt magnesite (magnesium oxide) This is derived by heating magnesite, and contains about 50% magnesium. It is sold in granulated form and its NV is 180–220.

Specialty Minerals Minerals Technologies Inc.

Talcs protect your car bumpers from damage and your house paints from weathering. Ground calcium carbonates (GCCs) make stuccos bright, roof shingles durable, and chewing gums chewy. PCCs and GCCs come

Calcium Carbonate (Limestone) Mosaic Crop Nutrition

Calcium carbonate, the chief component of limestone, is a widely used amendment to neutralize soil acidity and to supply calcium (Ca) for plant nutrition. The term “lime” can refer to several products, but for

Crushed Calcium Vitamins for a Vegetable Garden

2017年9月21日As you might expect, crushed calcium carbonate tablets will have a similar effect to adding agricultural lime. It may have an unwanted additional effect on your budget, however; calcium supplements aren't cheap. But if you stop taking calcium supplements and find yourself with a lot of leftover tablets, try feeding them to your plants.

Make Water Soluble Calcium At Home Growing

Water soluble calcium is ideal for farmers and gardeners who wish to give their plants and crops a quick calcium boost. It prevents crops and certain plants from overgrowing, increases the longevity and hardness of fruits,

How to Add Calcium to Soil The Spruce

2021年6月29日Lime. (Calcium carbonate and other forms of mined limestone) Adding lime to your soil is the biggest calcium booster you can give your soil but it also raises your soil pH, making it less acidic. Garden

Cement from CO 2 : A Concrete Cure for Global

2008年8月7日Calera's process takes the idea a step forward by storing the CO 2 in a useful product. The U.S. used more than 122 million metric tons of Portland cement in 2006, according to the Portland Cement...

Garden Plot: Tums can help tomatoes, even when they don’t

2019年5月3日Then add calcium to prevent blossom end rot: a dozen crushed eggshells, a dozen crushed calcium carbonate tablets or a half- cup of a calcium-rich organic plant specifically...

TEIR, S., ELONEVA, S., ZEVENHOVEN, R., 2005 Production of

a carbonate free calcium silicate rock, e.g. wollastonite (CaSiO 3), 200 kt of CO 2 emissions from lime kilns per year would be prevented. This reduction in CO 2 emissions would save 5.2 M€ per year of CO 2 emission allowances. 2. Precipitated calcium carbonate (PCC) Calcium carbonate occurs abundantly in several natural minerals. It

IJMS Free Full-Text Calcium-Based Antimicrobial Peptide

2022年9月26日Font Size: Aa Aa Aa. The shells for preparation of CAPCS were crushed and placed under vacuum conditions and 600 °C for 3 h, calcinated under mixed gas (40% air and 60% CO) and 1000 °C for 2 h, and then crushed with a micro nano pulverizer to obtain shell nano powders characterized with calcium carbonate porous