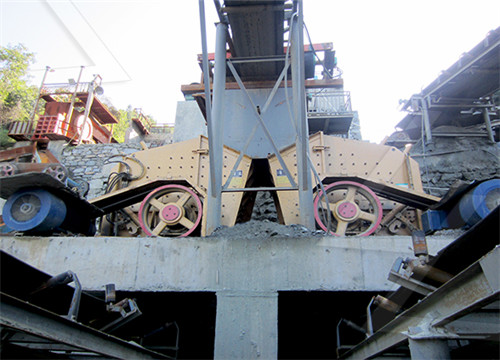

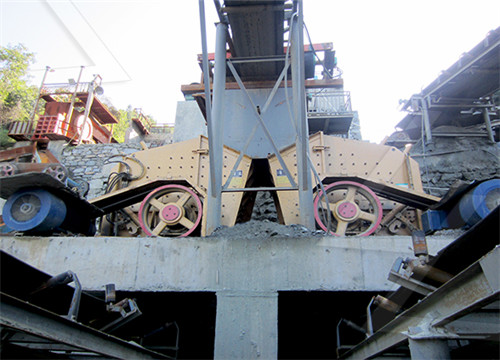

Ore Dressing Equipment Cu Pb Zn Flotation Machine

Cu-Pb-Zn, Copper-Lead-Zinc Ores, Copper Lead Zinc Flotation

Yantai Cu-Pb-Zn Ore Dressing Process It is reported that more than 90% of non-ferrous metal ores (copper, lead, zinc, etc.) adopt flotation process, especially for those with fine grain and complex symbiosis. Flotation process can achieve ideal separation effect, and separately recover low-grade ore then enrich multiple high-grade concentrates.

Cu-Pb-Zn Dressing Process Xinhai

Case 1Case 2Case 3Other CasesThere are many cases of Xinhai Cu-Pb-Zn Dressing Process. Welcome to visit our company! A copper-lead-zinc dressing plant in northwest of China, Xinhai adopted parts preferential flotation based on technology advantages of preferential and mixed flotation and combined with the ore characteristics. This plant obtained good beneficiation indexes: lea...

Pb-Zn Mineral Processing JXSC Mineral

Pb-Zn ores divide into sulfide Pb-Zn ore and oxide Pb-Zn ore. The most widely used in separating sulfide Pb-Zn ore is flotation. The sulfide Pb-Zn ore process divides into priority flotation processes, mix-separating

Cu-Pb-Zn Dressing Process

2015年7月17日A lead-zinc dressing plant in Yunnan,,due to the mining depth increasing, ore properties had changed and the grade of lead and zinc concentrate decreased, so the original flotation is not suitable.

Cu, Pb, Zn Separation Froth Flotation (SulphideOxide

Cu, Pb, Zn Separation Froth Flotation (SulphideOxide) MetallurgistMineral Processing Engineer To participate in the 911Metallurgist Forums, be sure to JOINLOGIN Use Add New Topic to ask a New Question/Discussion about Flotation. OR Select a Topic that Interests you.

Cu-Pb-Zn Dressing Process

2015年9月29日The Yunnan Cu-Pb-Zn project adopts the mixed flotation, preferential flotation of copper and lead concentration, regrinding and re-floatation of copper lead concentration due to the increasing

Cu-Pb-Zn Production Line uwas

A copper-lead-zinc ore dressing plant in Sweden with the daily output of 1000t, copper content of 0.58%, lead content of 2.85% and zinc content 4.90%; Xinhai adopted copper-lead mixed flotation. Final copper concentrate contains copper 20.25% and lead 6.75%, and the lead concentrate contains lead 58.73% and copper 3.40%.

pH Ranges for Sequential Cu Pb Zn Flotation Separation

2015年12月6日Float Metals One-by-One Selectively: Since our objective is to sequentially float Copper, then Lead, than Zinc while rejecting Pyrite, let us explore how we can separate Cu/Pb/Zn from Fe: pH 6-6.5 is where

Mineralogy and Innovative Flash Flotation Separation of Cu-Pb-Zn

2022年8月19日The results of the preliminary tests demonstrated that the Cu-Pb-Zn bulk flotation and partial Cu-Pb bulk flotation, followed by separation deal with a complex process flowsheet and reagent scheme, were difficult to realize the purposes of “discarding gangue minerals as soon as possible” as well as the Cu-Pb-Zn separation, due to good

Cu-Pb-Zn, Copper-Lead-Zinc Ores, Copper Lead Zinc Flotation

Yantai Cu-Pb-Zn Ore Dressing Process It is reported that more than 90% of non-ferrous metal ores (copper, lead, zinc, etc.) adopt flotation process, especially for those with fine grain and complex symbiosis. Flotation process can achieve ideal separation effect, and separately recover low-grade ore then enrich multiple high-grade concentrates.

Cu-Pb-Zn Dressing Process Xinhai

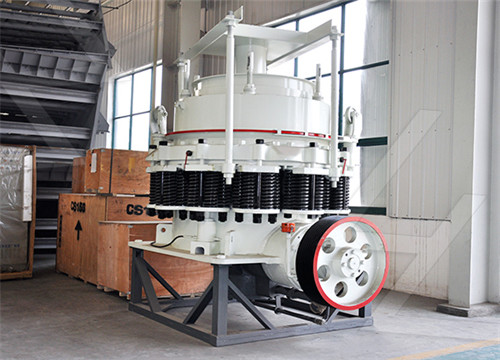

Cu-Pb-Zn Dressing Process 【Process Advantages】 Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic flotation reagents is

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

With Class B design qualifications in the metallurgical industry, rich in ore mining, beneficiation, smelting technology and experience, completed more than 2,000 mine design and research, not only can provide customers with a reasonable process, but also can provide customized equipment configuration. PROCESS New Energy Mineral

Flowsheet development for selective Cu-Pb-Zn recovery at Rosh

2018年6月15日This would enable the Pb circuit to produce a grade of 65% Pb at 81% recovery, and the Zn circuit, a grade of 57% Zn at 97% recovery. Mineralogical analysis of the final Pb and Zn products confirmed the need for the re-grinds. For the high-Cu ore, the challenge was to produce three distinct Cu, Pb, and Zn concentrates.

Cu-Pb-Zn, Copper-Lead-Zinc Ores, Copper Lead Zinc Flotation

Process. With the principle of " easiness to hardness ", Yantai divides the recovered minerals into two parts: easy-to-float and difficult-to-float according to the difference of natural floatability, and then separate the copper,

Cu-Pb-Zn Dressing Process

2015年7月17日【Process Advantages】Cu-Pb-Zn Dressing Process Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic

Cu-Pb-Zn Production Line uwas

A copper-lead-zinc ore dressing plant in Sweden with the daily output of 1000t, copper content of 0.58%, lead content of 2.85% and zinc content 4.90%; Xinhai adopted copper-lead mixed flotation. Final copper concentrate contains copper 20.25% and lead 6.75%, and the lead concentrate contains lead 58.73% and copper 3.40%.

Cu-Pb-Zn Dressing Process

2015年9月29日The Yunnan Cu-Pb-Zn project adopts the mixed flotation, preferential flotation of copper and lead concentration, regrinding and re-floatation of copper lead concentration due to the increasing

Flowsheet development for selective Cu-Pb-Zn recovery at

2018年6月15日For treating such a new ore, bulk Cu-Pb flotation followed by Zn flotation has been recommended (Sehlotho et al., 2018). Lime use and functionality in sulphide mineral flotation: A review Article

The Ultimate Guide to 4 Ilmenite Processing Methods

The beneficiation methods of ilmenite mainly include gravity separation, magnetic separation, flotation, combined beneficiation and so on. +86 ; If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements! The gravity separation method is to

EPC/Turnkey Service-ball mills-flotation cells-mineral dressing

Cu-Pb-Zn Dressing Process; Chrome Ore Processing Plants; Price War of Molybdenum Ore Dressing Equipment—Xinhai, the Winner; Xinhai is your best choice! Phosphorite Dressing Method Flow Charts; Aspects Needed Attention in Flotation Machines Maintenance and Repair; Efficient Improved Thickener Sludge Flow Analysis;

How to Select the Froth Flotation Method Used in the Extraction

2020年2月26日Here are 5 commonly used froth flotation methods for Pb-Zn sulfide ore extraction: Priority froth flotation method. Mixed froth flotation method. Iso-flotation method. Differential branching flotation method. Potential-controlled flotation method. The Pb-Zn sulfide ore is often associated with a variety of valuable components, such as lead

Features and Flotation of Complex Cu-Pb-Zn Sulphides

Problems arising during flotation of complex Cu-Pb-Zn sulphide ores are in general of geological origin. The features of these ores are reviewed, stressing that mineralogical studies extending to process mineralogy are prerequisite for a consistent flotation process. Some examples affecting flotation are given.

Mineralogy and Innovative Flash Flotation Separation of Cu-Pb-Zn

2022年8月19日The results of the preliminary tests demonstrated that the Cu-Pb-Zn bulk flotation and partial Cu-Pb bulk flotation, followed by separation deal with a complex process flowsheet and reagent scheme, were difficult to realize the purposes of “discarding gangue minerals as soon as possible” as well as the Cu-Pb-Zn separation, due to good

Cu-Pb-Zn Dressing Process Xinhai

Cu-Pb-Zn Dressing Process 【Process Advantages】 Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic flotation reagents is

Flowsheet development for selective Cu-Pb-Zn recovery at Rosh

2018年6月15日This would enable the Pb circuit to produce a grade of 65% Pb at 81% recovery, and the Zn circuit, a grade of 57% Zn at 97% recovery. Mineralogical analysis of the final Pb and Zn products confirmed the need for the re-grinds. For the high-Cu ore, the challenge was to produce three distinct Cu, Pb, and Zn concentrates.

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

With Class B design qualifications in the metallurgical industry, rich in ore mining, beneficiation, smelting technology and experience, completed more than 2,000 mine design and research, not only can provide customers with a reasonable process, but also can provide customized equipment configuration. PROCESS New Energy Mineral

Cu-Pb-Zn, Copper-Lead-Zinc Ores, Copper Lead Zinc Flotation

Process. With the principle of " easiness to hardness ", Yantai divides the recovered minerals into two parts: easy-to-float and difficult-to-float according to the difference of natural floatability, and then separate the copper,

Cu-Pb-Zn Dressing Process

2015年7月17日【Process Advantages】Cu-Pb-Zn Dressing Process Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic

Cu-Pb-Zn Dressing Process

2015年9月29日The Yunnan Cu-Pb-Zn project adopts the mixed flotation, preferential flotation of copper and lead concentration, regrinding and re-floatation of copper lead concentration due to the increasing

Flowsheet development for selective Cu-Pb-Zn recovery at

2018年6月15日For treating such a new ore, bulk Cu-Pb flotation followed by Zn flotation has been recommended (Sehlotho et al., 2018). Lime use and functionality in sulphide mineral flotation: A review Article

How to Select the Froth Flotation Method Used in the

2020年2月26日Here are 5 commonly used froth flotation methods for Pb-Zn sulfide ore extraction: Priority froth flotation method. Mixed froth flotation method. Iso-flotation method. Differential branching flotation

Cu-Pb-Zn Production Line uwas

A copper-lead-zinc ore dressing plant in Sweden with the daily output of 1000t, copper content of 0.58%, lead content of 2.85% and zinc content 4.90%; Xinhai adopted copper-lead mixed flotation. Final copper concentrate contains copper 20.25% and lead 6.75%, and the lead concentrate contains lead 58.73% and copper 3.40%.

The Ultimate Guide to 4 Ilmenite Processing Methods

The beneficiation methods of ilmenite mainly include gravity separation, magnetic separation, flotation, combined beneficiation and so on. +86 ; If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements! The gravity separation method is to

EPC/Turnkey Service-ball mills-flotation cells-mineral dressing

Cu-Pb-Zn Dressing Process; Chrome Ore Processing Plants; Price War of Molybdenum Ore Dressing Equipment—Xinhai, the Winner; Xinhai is your best choice! Phosphorite Dressing Method Flow Charts; Aspects Needed Attention in Flotation Machines Maintenance and Repair; Efficient Improved Thickener Sludge Flow Analysis;

Lime use and functionality in sulphide mineral flotation: A review

2019年11月1日For treating such a new ore, bulk Cu-Pb flotation followed by Zn flotation has been recommended (Sehlotho et al., 2018). An example of a sequential Cu-Pb-Zn flowsheet is given in Fig. 14 . A first flotation stage is carried out at low pH (pH 6), in which the copper sulphide is floated while both galena and sphalerite are depressed.

mill/sbm cu zn pb machinery mineral processing.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.