Primary Crushing Equipments Used In Power Plant

All crusher types for your reduction needs Metso Outotec

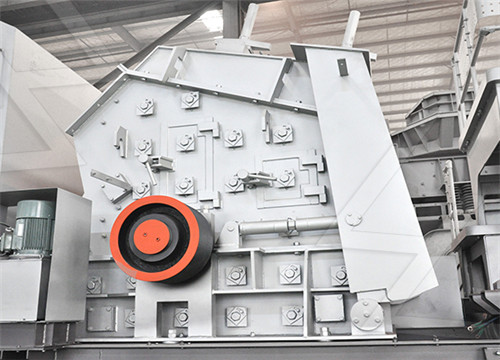

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers

Primary Crusher an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary

What Is Primary, Secondary, and Tertiary Crushing?

根据热度为您推荐•反馈

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers,

Primary Crushing Mineral ProcessingMetallurgy

2016年2月26日The primary crushing setup is closely linked to the quarrying or mining operation, and it is only by careful adjustment of all

Different types of crushing equipments Constro Facilitator

2020年5月6日A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or

Crushing Equipment For Sale IronPlanet

Buy used Crushing Equipment from Metso, mpl, Cedarapids, , Eagle, MEM and more. Generators and Power Equipment. Heating and Cooling

Crusher Aggregate Equipment For Sale

2023年3月9日TractorEquipment Company. Birmingham, Alabama 35202. Phone: (205) 708-7059. Email Seller Video Chat. Adding to “Used Equipment” inventory, this low hour mpl Cone Crusher, Year

Used Mobile Primary Crushing Plant for sale. Metso equipment

Search for used mobile primary crushing plant. Find Metso, mpl Reiner, Minyu, Baioni Nardi, Cedarapids, and Keestrack for sale on Machinio.

Primary Crusher/ Rotary breaker/ Mazor equipment/ Coal

2021年7月6日Primary Crusher/ Rotary breaker/ Mazor equipment/ Coal handling plant/ CHP/ Thermal power plant 4,063 views Jul 6, 2021 60 Dislike Share AG _EDITS 306

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

How to choose the right primary crusher for your plant?

2023年2月1日 group. Choosing the right primary crusher for your plant requires careful consideration of several factors, including: Capacity: Determine the capacity required for your plant and select a

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日Eagle Crusher offers a comprehensive portfolio of closed-circuit and open-circuit portable crusher plants alike, manufacturing powerful equipment like horizontal-shaft impactors, jaw crushers, and

Primary crusher, Primary crushing and screening plant All

hydraulic impact crusher R1000S mobile compact fine Capacity: 280 t/h Motor power: 235 kW 250 kW Weight: 31 t 35.5 t R1000S Track-Mounted Impact Crusher HIGH OPERATING COMFORT MANY TECHNICAL REFINEMENTS OPTIMUM EFFICIENCY! Rocksters new impact crusher R1000S is especially designed to increase operating and

Crushing Equipment For Sale IronPlanet

Whether looking for a Cone Crusher, Impact Crusher, Jaw Crusher or other various type, IronPlanet offers several makes and models that can help efficiently and effectively complete your task. Browse popular models from top manufacturers including Cedarapids Crushers, Metso Crushers and others.

What type of crushing machinery to choose for coal grinding?

2023年3月9日Here are some of the most common types of crushing machinery used for coal grinding: Jaw Crushers: Jaw crushers are a popular choice for primary crushing of coal. They are designed to...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. The reason for inspection depends on the component and its effect on plant operation. But one of the main systems of thermal power plant is coal-handling system.

Used Mobile Primary Crushing Plant for sale. Metso equipment

Search for used mobile primary crushing plant. Find Metso, mpl Reiner, Minyu, Baioni Nardi, Cedarapids, and Keestrack for sale on Machinio.

Crushing in Mineral Processing

2015年12月26日Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a

Crusher Direct Sale/Quarry Machine Complete Production

hengtong Model PE200x300 jaw crusher feeding size is 170 mm, output size is 15-40mm, capacity is 3-9 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries.

Used Le Pont for sale. Polygonmach equipmentmore Machinio

2015 Leopard 39 Powercat. USED. Manufacturer: Leopard. ROBERTSONCAINE Leopard 39 PC Extended Hull (2015) 319 000 Euros VAT Incl ! A RARE OPPORTUNITY OF MODERN, COMPACT AND ATTRACTIVE POWERCAT : The Leopard 39 PC features a roomy saloon and galley plus 4 cabin Dania Beach, FL, USA.

DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold

The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in the software

Crushing Equipment for Sale and Rent ing

Mobile or portable jaw rock crushers are used as primary rock crushers because they accept large and highly variable material inputs. jaw rock crushers are designed to provide aggressive rock crushing action and high production even at

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

Primary Crusher an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher.

How to choose the right primary crusher for your plant?

2023年2月1日Choosing the right primary crusher for your plant requires careful consideration of several factors, including: Capacity: Determine the capacity required for your plant and select a...

Gyratory VS Jaw Crushers: Advantages

2016年2月28日Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for

National Renewable Energy Laboratory (NREL) Home Page NREL

National Renewable Energy Laboratory (NREL) Home Page NREL

What type of crushing machinery to choose for coal grinding?

2023年3月9日Here are some of the most common types of crushing machinery used for coal grinding: Jaw Crushers: Jaw crushers are a popular choice for primary crushing of coal. They are designed to...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. The reason for inspection depends on the component and its effect on plant operation. But one of the main systems of thermal power plant is coal-handling system.

Used Mobile Primary Crushing Plant for sale. Metso equipment

Search for used mobile primary crushing plant. Find Metso, mpl Reiner, Minyu, Baioni Nardi, Cedarapids, and Keestrack for sale on Machinio.

Crusher Direct Sale/Quarry Machine Complete Production

hengtong Model PE200x300 jaw crusher feeding size is 170 mm, output size is 15-40mm, capacity is 3-9 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries.

Used Le Pont for sale. Polygonmach equipmentmore Machinio

2015 Leopard 39 Powercat. USED. Manufacturer: Leopard. ROBERTSONCAINE Leopard 39 PC Extended Hull (2015) 319 000 Euros VAT Incl ! A RARE OPPORTUNITY OF MODERN, COMPACT AND ATTRACTIVE POWERCAT : The Leopard 39 PC features a roomy saloon and galley plus 4 cabin Dania Beach, FL, USA.

® C Series™ jaw crushers Metso Outotec

® C Series™ jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs. Contact our sales experts Uncompromised reliability

Crushing Equipment for Sale and Rent ing

Mobile or portable jaw rock crushers are used as primary rock crushers because they accept large and highly variable material inputs. jaw rock crushers are designed to provide aggressive rock crushing action and high production even at

Mineral Processing Plant Design University of Technology, Iraq

The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million. It’s necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects: • Earthworks • Mechanical • oncrete

DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold

The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in the software