Heat Balance For Vertical Mill

A case study on energy and exergy analyses for an

2021年2月1日Another cement plant in Indiana energy balance revealed that the amount of waste heat is about one-third of total input energy and about half of this waste energy can be recovered . the energy and exergy analyses of an industrial-scale vertical roller

Excel Sheet Calculates Vertical Raw Mill Heat Balance

2018年7月11日Amazing simple tool to calculate Vertical Mill heat balance by Loesche Adding your simple analysis and process parameters ===> finally you get the Balance

Vertical Mill Calculations PDF Mill (Grinding) Nozzle

高达$3返现f For vertical mills the dam ring height is often referred to as "% of table diameter". The optimum height normally being in the range 2.5 4% of table diameter.

How Does Temperature Affect Accuracy in CNC Machining?

Testing of Thermal Performance of Machine ToolsControl of Thermal Deformation of Machine ToolsOutlook and Vision

1. Purpose of machine tool thermal performance testThe key to controlling thermal deformation in machine tools is a thorough understanding of changes in ambient temperature, heat sources, and temperature changes within the machine tool, as well as the response of key points (deformation displacement) through thermal testing. By m2. The principle of machine tool thermal deformation testThe thermal deformation test begins by measuring the temperature of several relevant points, including: (1) Heat source: such as the feed motor, spindle motor, ball screw drivepair, guide rail, and spindle bearings of each part. (2) Auxiliary devices:including the hydraulic system, refrigera在machinemfg上查看更多信息预计阅读时间:9 分钟

Vertical Raw Mill Heat Balance Solution PDF Scribd

高达$3返现84.1 Mill outlet gas flow. 6.4. 1.6. 7.9. 100. In a vertical roller mill the % of false air is usely between 5 and 10%. 330000 Nm3/h on wet. Gas coming from the kiln 270C. 307230 Nm3/h on dry.

Heat balance calculators

Heat balance calculators. The calculation of the thermical balance of the ball mill is now proposed according 2 methods: The first method, we know the ventilation of the mill +

heat balance for vertical mill.md main liach2022 / mpl

Open sidebar. liach2022; mpl; Repository; main

Ball Mill Heat Balance Explanation

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

Vertical roller mill Wikipedia

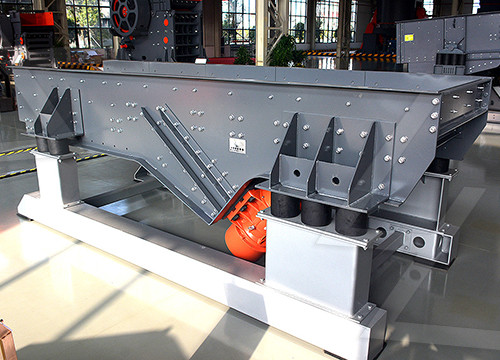

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many

sbm/sbm heat balance of vertical roller mill.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

A case study on energy and exergy analyses for an industrial-scale

2021年2月1日The energy and exergy balances of this grinding process are defined based on process flows data containing the mass rate, specific heat constant, and temperature that is demonstrated in Fig. 2. For the thermodynamic assessment of the VRM, the following assumptions were considered: 1. The working condition during the grinding process is

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal

Tool HoldersTool Clamping HAIMER

The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Therefore, the JIS B 6339-2 interface is primarily suitable for applications with a spindle speed of up to 12,000 rpm. BT30 BT30 with face contact BT40 BT40 with face contact BT50 BT50 with face contact

How Does Temperature Affect Accuracy in CNC Machining?

After continuous automatic grinding for 1 hour, the dimensional change range increases to 12m and the coolant temperature rises from 17°C at startup to 45°C. This increase in temperature causes the spindle journal to elongate and the bearing clearance at the front of the spindle to increase.

Excel Sheet Calculates Vertical Raw Mill Heat Balance Solution

2018年7月11日Amazing simple tool to calculate Vertical Mill heat balance by Loesche Adding your simple analysis and process parameters ===> finally you get the Balance difference. You can use it Free of charge

heat balance for vertical mill.md main liach2022 / mpl GitLab

Open sidebar. liach2022; mpl; Repository; main

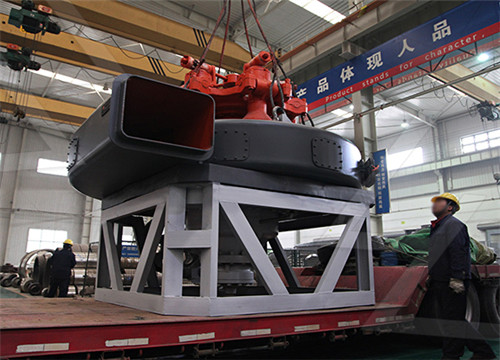

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Vertical Height = 2 x Gape Width of Jaw > 1.3 x Gape < 3.0 x Gape Throw = 0.0502 (Gape) 0.85 Gape is measured in meters. Jaw crusher action Jaw Crusher Sizes and Power Ratings Size is specified in terms of the gape and width, typically listed as gape x width. Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250-300 kW.

Mill Heat Balance PDF Heat Physical Quantities

2008年11月20日mill heat balance Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. mill heat balance mill heat balance Open navigation menu Close suggestionsSearchSearch enChange Language close menu Language English(selected) Español Português Deutsch Français Русский Italiano

Dokumen Tips Vertical Raw Mill Heat Balance Solution

In a vertical roller mill the % of false air is usely between 5 and 10% 330000 Nm3/h on wet Gas coming from the kiln 270°C 307230 Nm3/h on dry Gas temperature 100°C % th/h % CO2 26.1 9687 CO2 23.07 O2 6.77 1812 O2 8.39 CO 0.1 26 CO 0.06 N2 67.2 17363 N2 68.53 H20 6.9 2250 H20 11.8 100.17 31137 100.05 Heat balance Inputs

VF-11/40 40-Taper Mill Vertical Mills Haas CNC Machines

VF-10/40. CNC Vertical Mill with 120" x 32" x 30" travels. 40 Taper. 3 Axis. 8.1k RPM. 30+1 Tool Capacity. Starting at US$237,995.

sbm/sbm heat balance of vertical roller mill.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

What is a Mill Test Report? Paul Mueller

A heat code (or heat number) tracks which batch of metal an individual piece of metal came from. Metal providers and component manufacturers have a tracking process to ensure quality and reliability. This tracking process includes at least these four items: Mill Heat Codes Material Purchase Order Component Manufacturer Heat Codes

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal

VF-9/50 50-Taper Mill Vertical Mills Haas CNC

CNC Vertical Mill with 120" x 40" x 30" travels 50 Taper 3 Axis 7.5k RPM 30+1 Tool Capacity Starting at US$292,595 Learn More BuildPrice Cutting with a 50 Taper VF Series 50-taper machines are workhorses,

VF-11/40 40-Taper Mill Vertical Mills Haas CNC

VF-10/40. CNC Vertical Mill with 120" x 32" x 30" travels. 40 Taper. 3 Axis. 8.1k RPM. 30+1 Tool Capacity. Starting at US$237,995.

Tool HoldersTool Clamping HAIMER

The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Therefore, the JIS B 6339-2 interface is primarily suitable for applications with a spindle

Excel Sheet Calculates Vertical Raw Mill Heat Balance Solution

2018年7月11日Amazing simple tool to calculate Vertical Mill heat balance by Loesche Adding your simple analysis and process parameters ===> finally you get the Balance difference. You can use it Free of charge

(PDF) Population balance model approach to ball mill

2014年1月1日The work demonstrates the application of the population balance model in the optimization of a full-scale ball mil circuit grinding pellet fines with the aim to evaluate the optimal solids

heat balance for vertical mill.md main liach2022 / mpl GitLab

Open sidebar. liach2022; mpl; Repository; main

Design methodology of heat recovery steam generator in electric

2018年9月12日By using a HRSG for recovering the waste heat from the exhaust of a 60-MW gas turbine, an additional power of 35.14 MW can be generated, thus increasing the overall plant efficiency from 33% to 52%. The heat transfer coefficients of gas are weak; therefore, the designed HRSG has a large area to produce steam at high pressure and

Raw Mill Heat Balance PDF Scribd

RAW MILL HEAT BALANCE Ref. : Rev. : Separator : Product Size : Moisture out : JS / SM 0 RAR- 47.5 12% R on 90 0.5%. Vertical Raw Mill Heat Balance Solution. Sai Sricharan Reddy. KilnLine Operation.

Thermal Regulation Lecture Cornell University

S = rate of storage of heat in the body. Heat balance exists when M W = R + C + E + L + K + S R + C + K = 72% of heat loss Eskin = 15% (Excretion of feces and urine = 3%) Llungs = 7% exhaled, 3% warming inhaled Ideally S should equal 0 when the body is in heat balance i.e. heat production = heat loss with no storage.

heat balance of vertical roller mill

1 tool to calculate Vertical Mill heat balance by Loesche In a vertical roller mill the of false air is usely between 5 and 10 330000 Nm3/h on wet 392572 Nm3/h on wet Gas coming from the kiln 270 176 C 307230 Nm3/h on dry Gas temperature VRM

mill/sbm balance calculations in vertical roller mills.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

Inside Heat Balance: Engineering Reference — EnergyPlus 8.0

The heat balance on the inside face can be written as follows: where: = Net longwave radiant exchange flux between zone surfaces. = Net short wave radiation flux to surface from lights. = Longwave radiation flux from equipment in zone. = Conduction flux through the wall. = Transmitted solar radiation flux absorbed at surface.