Rendah Model Ball Mill

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and

进一步探索

Lab Ball MillsLaboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg Ball Mills The Laboratory StoreBall Mills Best of 2023 911MetallurgistGrinding Mill DesignBall Mill Manufacturer根据热度为您推荐•反馈

Planetary Ball Mill PM 200 RETSCH short grinding times

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The extremely high centrifugal

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日An Improved C ontact Model for Ball Mill Simulation by th e . Discrete Element Method. Adva nced Powder T echnology, V ol. 13, 2002, No 1, 25-41. 32. M i s h r a, B. K.

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills

Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic

Ball End Mills McMaster-Carr

Cobalt Steel Ball End Mills with Two Milling Ends. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide

id/rendah model ball mill.md at main lqdid/id

Contribute to lqdid/id development by creating an account on GitHub.

rendah model ball mill lange-vandamme.site

The Emax is an entirely new type of ball mill for high energy input. Get Quote WhatsApp; Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日The adaption of the kinematic model from a planetary ball mill to the high-energy Emax mill was detailed in our previous work (Kessler et al., 2018). To account for the Emax mill operation, the relation ω J = − ω P was obtained from manufacturer patent (Mahler and Pankratz, 2011). Hence, (14) becomes (16), enabling estimating the energy

Real-time reconciliation of a geometallurgical model based on ball mill

The Bond Ball Mill Work Index (Wi) is one such spatial estimate which remains difficult to infer correctly. The Wi defines the specific energy (kWh/ton) required in grinding a ton of ore in the ball mill from a very large size (infinite) to 100 m (Lynch et al. 2015). At the time of writing, this variable is of particular interest for the

Planetary Ball Mill PM 200 RETSCH short grinding times

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization

Grinding in Ball Mills: Modeling and Process

2012年6月1日The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an abrasion-resistant elastomer, put in vibrating motion by high-tensile steel springs [28]....

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE Ball Mills are supplied in a wide variety of capacities and specifications. DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h).

System dynamics model of output of ball mill

2021年2月15日The fitting degree is above 0.8, and the authenticity is high. The simulation results show that the impact energy of barrel grinding, the grinding powder fineness, and the pressure ratio in the...

id/ball mill rendah.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.

U. S. Stoneware: Ceramic Ball Mills

Ceramic Ball Mill with optional explosion-proof controls and cooling jacket for temperature control. A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts, can be installed

rendah model ball mill lange-vandamme.site

The Emax is an entirely new type of ball mill for high energy input. Get Quote WhatsApp; Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball Mills are used wherever the highest degree of fineness is required. The PM 100 is a convenient benchtop model with 1 grinding station. Get Quote WhatsApp; Ball mill

rendah model ball mill sushipotala

الصفحة الرئيسية / rendah model ball mill. 100+ يحب Research on Optimal Control Model for Ball Mill . As the key equipment in coal-fired power plants, the optimal control problem of ball mill is an important factor affecting the efficient operation of the mill. In this , the output model, energy consumption model and

Ball Mill Working Principle And Main Parts GitHub

mpl ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industries.This new type ball mill with

Used Ball-mills For Sale

UNUSED mpl 22' x 38' (6706mm x 11582mm) Ball Mill, 10,000 kW (13,410 HP) Twin Pinion 50 Hz Motors and Gear Reducers. Inventory ID: 6C-CM02. UNUSED mpl 22' x 38' (6706mm x 11582mm) Ball Mill,

Planetary Ball Mill PM 100 CM RETSCH gentle size reduction

Download. The Planetary Ball Mill PM 100 CM is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and

Ball Mill an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日The adaption of the kinematic model from a planetary ball mill to the high-energy Emax mill was detailed in our previous work (Kessler et al., 2018). To account for the Emax mill operation, the relation ω J = − ω P was obtained from manufacturer patent (Mahler and Pankratz, 2011). Hence, (14) becomes (16), enabling estimating the energy

Real-time reconciliation of a geometallurgical model based on ball mill

The Bond Ball Mill Work Index (Wi) is one such spatial estimate which remains difficult to infer correctly. The Wi defines the specific energy (kWh/ton) required in grinding a ton of ore in the ball mill from a very large size (infinite) to 100 m (Lynch et al. 2015). At the time of writing, this variable is of particular interest for the

Planetary Ball Mill PM 200 RETSCH short grinding times

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE Ball Mills are supplied in a wide variety of capacities and specifications. DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h).

Ball Mill Critical SpeedWorking Principle YouTube

2015年6月20日https://911metallurgist/blog/ball-mill Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM s...

id/ball mill rendah.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.

U. S. Stoneware: Ceramic Ball Mills

Ceramic Ball Mill with optional explosion-proof controls and cooling jacket for temperature control. A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts, can be installed

rendah model ball mill sushipotala

الصفحة الرئيسية / rendah model ball mill. 100+ يحب Research on Optimal Control Model for Ball Mill . As the key equipment in coal-fired power plants, the optimal control problem of ball mill is an important factor affecting the efficient operation of the mill. In this , the output model, energy consumption model and

Rendah Model ball mill laterrassesaintpierre.fr

Rendah Model ball mill. Home; Rendah Model ball mill; Bola Besi Cast High Medium Low untuk Pabrik Ball Mill Semen Model dan Spesifikasi Nama Bahan Unsur kimia Kekerasan C Si M N S P Cr HRC Bola besi cor Cr1 khusus 2.0-3.0 20 58-64 Cr2 khusus 2.0-3.0 15 58-64 Cr

rendah model ball mill theclaunet.it

Small Pilot Plant Grinding Mill. The 911MPEPPGR426 is a small 300 kilo to 35 ton per 24 hour day capacity grinding mill acting primarily as a rod mill but can effortlessly be converted to a ball mill Thanks to the integrated spiral classifier, it forms an easy to operate closed-circuit grinding plant It includes a fine ore hopper, vibrating feeder and starter rod

Ball Mill Working Principle And Main Parts GitHub

mpl ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industries.This new type ball mill with

Planetary Ball Mill PM 100 CM RETSCH gentle size reduction

Download. The Planetary Ball Mill PM 100 CM is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and

Menghitung Kapasitas Ball Mill ardra.biz

Untuk ball mill, semakin besar radiusnya, maka semakin rendah kecepatan putarnya. Ball mill model 1200 x 3000 akan bekerja dengan baik jika kecepatan putarnya kurang atau sama dengan 36 rpm. Rumus Kecepatan Putar Ball Mill Model 1200 x 3000, Putaran ball mill dapat ditentukan dengan menggunakan pendekatan putaran kritis.

Modeling and simulation of continuous open circuit dry grinding

Prediction of continuous steady-state ball milling using the traditional population balance model requires knowledge of several functions, namely those describing the rate and distribution of breakag

- 破碎机型 号

- Kaolin Processing Equipment Manufacturers In Germany

- List Of Mining Equipment Manufacturers In Usa

- M-2000B碎石机水囊

- Automated Mineral Sample Preparation Of Coal Mine

- 水泥厂水渣

- Crushers Machine South Africa

- 破碎机西門子tc66

- 采用整车破碎

- 石灰石磨粉机厂家

- Method Of Querring Of Stone

- 日产300吨大米生产线需要多少钱

- 购磨粉机

- 圆振筛专业生产厂家适用对象

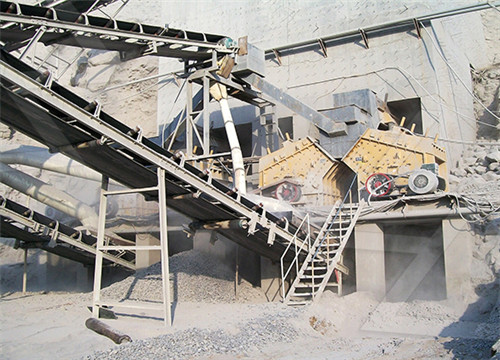

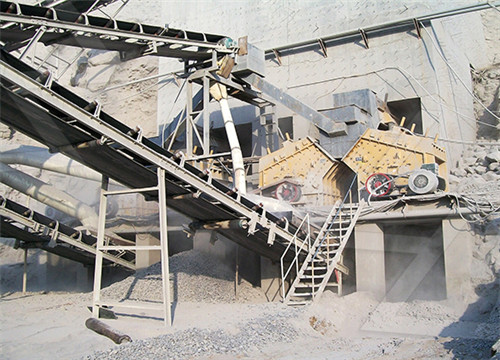

- Professional Manufacturer Mobile Crushing Plant With Reasonable Price