Ock Absorbing Material Cone Crusher

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

Cone Crushers MobileHigh Productivity Finlay

The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides

进一步探索

C-1540 Direct Drive Cone Crusher Mobile Tracked Crusher Maxtrak 1000 Cone Crusher Plant User Manual PD根据热度为您推荐•反馈

Cone Crushers MEKA CrushingScreening Plants

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour. The adjustable crushing chamber can provide the

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is

Aggregate and Mining Crusher Backing Copps Industries

Cone crushers are a form of compression crushing machines, which reduce the size of materials by squeezing or crushing them until they break. They consist of an eccentrically rotating steel component (i.e., the

LOCTITE Nordbak Crusher Backing Materials Kaman

• Cone crushers up to 7 ft. • Grinding mills • Primary gyratory crushers • Extreme hard rock crushing Backing Material 35248* * 2 gal. kit 5 gal. kit 55 gal.

Cone Crusher Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead

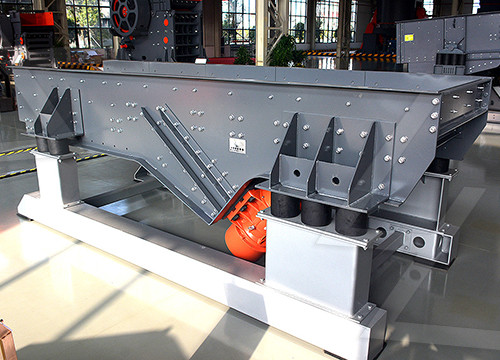

Vibration cone crusher for disintegration of solid materials

2018年11月15日In the course of the research, a mathematical analysis of the dynamics of the vibration crusher was carried out to determine the required mechanical parameters, which made it possible to adjust...

Ock Crushers Crusher Mills, Cone Crusher, Jaw Crushers

Rock crusher also called rock crushing equipment include jaw crusher, cone crusher, impact crusher and so on. Rock Crusher Compare Prices, Reviews and Buy at

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

C-1540 Direct Drive Cone Crusher Mobile Tracked

The large hopper/feeder has automated metal detection and a purge system to protect the cone and reduce downtime by removing metal contaminants via the purge chute. Additional benefits include, rapid set up time, ease

Cone Crushers MEKA CrushingScreening Plants

Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron, chrome, magnesite

LOCTITE Nordbak Crusher Backing Materials Kaman

• Cone crushers up to 7 ft. • Grinding mills • Primary gyratory crushers • Extreme hard rock crushing Backing Material 35248* * 2 gal. kit 5 gal. kit 55 gal. drum 5 gal. kit 340 850 9,350 n/a • Cone crushers up to 7 ft. • Grinding mills High Impact Backing Material • Cone crushers up to 7 ft. • Grinding mills

Energy Efficiency of a Cone Crusher with Stops

Abstract One of the main processes in the metallurgical, construction and mining industries is the process of grinding various materials as a primary raw materials preparation. The crushing of materials to obtain the required fraction annually consumes up to 4% of the world’s electricity production, and for a single mine, the share of energy consumption for

Understanding the Different Types of Crushers

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the

Real-Time Optimization of Cone Crushers Semantic

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Ok for wet and sticky materials. Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity 0.3 to 50

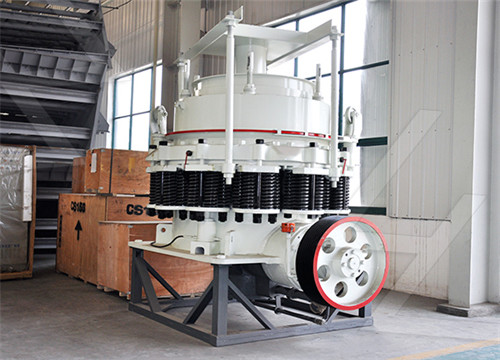

Large Capacity Symons Cs160 Cone Crusher Iron Ore Hard Stone

Large Capacity Symons Cs160 Cone Crusher Iron Ore Hard Stone Crushing Machine Price Symons Rock Stone Cone Crusher For Sale,Find Complete Details about Large Capacity Symons Cs160 Cone Crusher Iron Ore Hard Stone Crushing Machine Price Symons Rock Stone Cone Crusher For Sale,Large Capacity Symons Cs160 Cone Crusher Iron Ore

Ock Absorbing Material Cone Crusher kanjeevaramsilks

The hydraulic crusher is developed on the basis of digesting and absorbing various types of cone crushers with international advanced level in the 1980s. It is obviously different from the design of the traditional cone crusher in structure, and focuses on the main advantages of various types of cone crushers known so far.

Cone Crusher an overview ScienceDirect Topics

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a portable coordinate measurement machine.Ultrasonic profiling is also used. A more advanced system using a laser scanner tool to profile the mantle and concave produces

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is one of the most important indexes of cone crushers, which...

Loctite® Nordbak® Crusher Backing Materials YUMPU

2013年3月26日cone mantle loctite nordbak liner accelerator concave materials henkelna henkelna Number of Kits per Application Approximate number of 2 gallon kits (21.5 lbs. / 10 kg) of Nordback ® Backing Material required for crushers NORDBERG ® PRIMARY GYRATORY CRUSHERS Crusher Size HD 42-70 HD 54-80

6 Granite Crushers for Efficient Granite Crushing Fote Machinery

2023年2月28日The cone crusher has large output and stable production, and can be used in large-scale, high-output granite crushing production lines. More than 90% of the granite gravel is in perfect cubical shape, achieving low amount of needle and flake particles.

C-1540 Direct Drive Cone Crusher Mobile Tracked

The large hopper/feeder has automated metal detection and a purge system to protect the cone and reduce downtime by removing metal contaminants via the purge chute. Additional benefits include, rapid set up time, ease

Cone Crushers MobileHigh Productivity Finlay

The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides large reduction ratios and an excellent cubical shaped end product. The robust design of the plant enables it to accept an all in feed and makes it particularly suitable when

Cone Crushers MEKA CrushingScreening Plants

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour. The adjustable crushing chamber can provide the

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is one of the most important indexes of cone crushers, which...

Cone Crusher Liners: How to Select and When to

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side

All Metso Corporation catalogs and technical brochures

Metso MX™ Multi-Action Cone Crusher Brochure. 5 Pages. ® NP13NP15 Impact Crusher Brochure. 3 Pages. ® C150™ Jaw Crusher Brochure. 3 Pages. ® C130™ Jaw Crusher Brochure with changes to the cost of raw materials and exchange rates. HOW TO SOURCE PRODUCTS. Exhibit with us. FAQ. Brand list;

Real-Time Optimization of Cone Crushers Semantic Scholar

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production. These systems ordinarily focus on the crusher and not the yield of production process. In this

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Ok for wet and sticky materials. Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity 0.3 to 50

Understanding the Different Types of Crushers Agg-Net

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the setting between the two pieces of steel. Though the chamber is round in shape, the moving piece of steel is not meant to rotate.

Crusher Aggregate Equipment For Sale MachineryTrader

2023年3月9日Birmingham, Alabama 35202. Phone: (205) 708-7059. Email Seller Video Chat. Adding to “Used Equipment” inventory, this low hour mpl Cone Crusher, Year 2020 Hours 945 Located Forest Park, GA Sales Price $650,000.00 Unit clean and in excellent condition, Get Shipping Quotes. Apply for Financing.

LOCTITE Nordbak Crusher Backing Materials Kaman

• Cone crushers up to 7 ft. • Grinding mills • Primary gyratory crushers • Extreme hard rock crushing Backing Material 35248* * 2 gal. kit 5 gal. kit 55 gal. drum 5 gal. kit 340 850 9,350 n/a • Cone crushers up to 7 ft. • Grinding mills High Impact Backing Material • Cone crushers up to 7 ft. • Grinding mills

6 Granite Crushers for Efficient Granite Crushing Fote Machinery

2023年2月28日The cone crusher has large output and stable production, and can be used in large-scale, high-output granite crushing production lines. More than 90% of the granite gravel is in perfect cubical shape, achieving low amount of needle and flake particles.

Types of Rock Crushers Quarry Crushing Equipment Kemper

Gyratory crushers feature a conical head and concave surface (often lined with manganese steel) and break apart material by compression through what is known as eccentric movement. Like jaw crushers, gyratory crushers are often utilized in primary crushing stations, though they may sometimes be used as secondary crushers, as well. Cone

Loctite® Nordbak® Crusher Backing Materials YUMPU

2013年3月26日cone mantle loctite nordbak liner accelerator concave materials henkelna henkelna Number of Kits per Application Approximate number of 2 gallon kits (21.5 lbs. / 10 kg) of Nordback ® Backing Material required for crushers NORDBERG ® PRIMARY GYRATORY CRUSHERS Crusher Size HD 42-70 HD 54-80