Belt Feeder Design

Belt feeders Metso Outotec

Belt feeders are built according to strict safety standards, such as NRs (Brazilian regulations) and OSHA and MSHA (United States regulations). They include an

Belt Feeder MERRICK Industries, Inc.

A belt feeder can be used to transport and meter a wide variety of bulk materials. When the metering precision expectation is around ± 5%, the belt feeder can be designed to

进一步探索

Belt Feeders Brochure Metso Corporation PDF CatalogWeigh Belt Feeder MERRICK Industries, Inc.根据热度为您推荐•反馈

Belt Feeders FEECO International Inc.

Belt feeders are commonly used when material that is either stockpiled or loaded (at an uncontrolled rate) in a bin or hopper needs to be

Belt Feeder Don Valley Engineering Belt Feeders

Belt Feeders Horizontal and Inclined Belt Feeders are predominantly used for extracting bulk materials from bunkers, hoppers and stock piles or for

(PDF) Design of Belt and Apron Feeders An Overview

An overview of feeder design and performance focussing on belt and apron feeders is presented The importance of correct hopper and feeder interfacing is stressed The objective is to achieve uniform draw-down in

CONCEPTS OF FEEDER DESIGN AND PERFORMANCE

estimation of loads on feeders used in conjunction with funnel-flow, expanded-flow bins and gravity reclaim stockpiles is discussed. The design of feed chutes for directing the flow

Hopper SOME EXTRACTS FROM THE BOOK BELT FEEDER

The belt feeder discharge is positive volumetric in nature. The typical capacity range is up to 1500 m3/hour, for regularly used belt widths. However, belt feeders of higher capacities

Bulk solids handlingEngineering Feeder and Conveyor Design

Belt feeder calculations require knowledge of the consolidated silo or bin opening pressure for initial bin fill condition, as well as flow condition. Design techniques such as tapered

Belt Feeder Properly Designed

2018年10月19日Belt Feeder is placed bellow the hopper and it is designed to work flooded of material and take out only a required quantity of material in m3/sec. The

Belt Feeder MERRICK Industries, Inc.

A belt feeder can be used to transport and meter a wide variety of bulk materials. When the metering precision expectation is around ± 5%, the belt feeder can be designed to provide a desired feedrate downstream based on volume for every rotation of the headpulley.

Belt Feeders FEECO International Inc.

Belt feeders are commonly used when material that is either stockpiled or loaded (at an uncontrolled rate) in a bin or hopper needs to be introduced into the system at a controlled feed rate. Able to handle a variety of

Hybrid Apron Belt (HAB) Feeder

The HAB Feeder’s hybrid design combines both belt and apron feeder technology, utilising conventional conveyor belting bolted to the aprons, for a power-efficient and high-tonnage-capacity feeder. The reinforced

Belt Feeder Don Valley Engineering Belt Feeders

Basic Design. Don Valley Belt Feeders incorporate a robust rolled steel chassis on which are mounted the drive and tail pulleys, along with the tail pulley tensioning device, belt idlers and skirt plates. Discharge

Hopper SOME EXTRACTS FROM THE BOOK BELT FEEDER

The belt feeder discharge is positive volumetric in nature. The typical capacity range is up to 1500 m3/hour, for regularly used belt widths. However, belt feeders of higher capacities are also possible. As an example, a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. 1.3.2 Apron feeders

How to Design Efficient and Reliable Feeders for Bulk Solids

There are two basic types of feeders used in industrial plants: volumetric and gravimetric. As its name implies, a volumetric feeder modulates and controls the volumetric rate of discharge from a bin (e.g., cu. ft./hr.). The four most common types of such feeders are screw, belt, rotary valve, and vibrating pan. A gravimetric feeder, on the

Sidewinder Conveyor Design Software Sidewinder

This design philosophy ensures that many conditions which may have otherwise gone unchecked are accounted for in the design phase. For example, belt liftoff is automatically calculated using a “worn” belt mass

Bulk solids handlingEngineering Feeder and Conveyor Design

Belt feeder calculations require knowledge of the consolidated silo or bin opening pressure for initial bin fill condition, as well as flow condition. Design techniques such as tapered openings by 5 degrees divergence, and relieving the feeder angle by a few degrees, assists with minimising pull-out torques.

Belt Feeders Bulk Material Transport

Kase Belt Feeders are used to meter bulk materials from hoppers or bins. Belt Feeders utilize a flat belt and are flood-loaded in the inlet area. The bulk material is metered through an adjustable strike-off plate. The inlet area is completely enclosed with skirting to prevent spillage. Metering capacities up to 20,000 cubic feet per hour can

Design of a Material Handling Equipment: Belt

2014年1月16日For design optimization of machine components, stress analysis on chassis, impact analysis on feeder ramp and deflection analysis on conveyor belt are assessed using solid edge tool.

Belt Feeders TAKRAF TAKRAF GmbH

Belt feeder design thus needs to consider all specific requirements determined by the material being moved, as well as capacity and geometry. TAKRAF feeders combine a reinforced belt, robust heavy-duty idlers

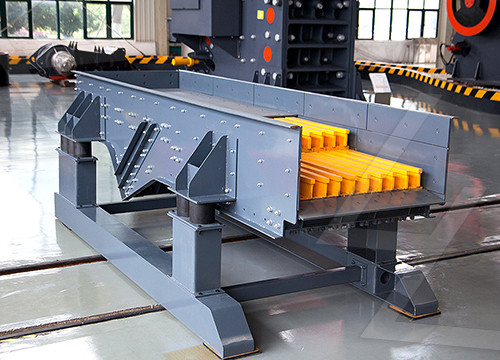

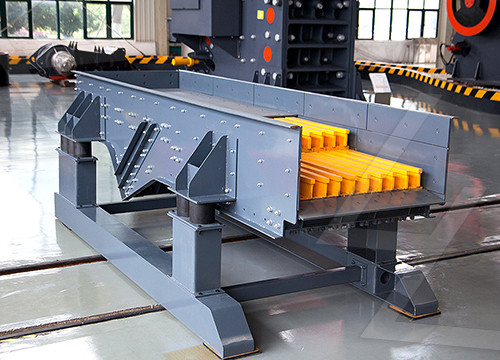

Belt Feeders MEKA CrushingScreening Plants

Belt feeder design thus needs to consider all specific requirements determined by the material being moved, as well as capacity and geometry. The rugged design and features such as robust heavy-duty idlers, frames, abrasion resistant liners and chute work help significantly increase service life.

How feeder design impacts silo discharge Processing Magazine

2022年12月20日A feeder must work in unison with the silo to ensure reliable flow. Screw, belt and rotary valve feeders are commonly used to maintain mass flow. Screw and belt feeders are typically used to control discharge from slotted or wedge-type hoppers (Figure 2, left) but can also be used to control discharge from conical hoppers (Figure 2, right).

Belt Feeder Design: Starting Load Calculations bulk-online

2018年9月18日| | A.E. Maton, Australia Belt Feeder Design: Starting Load Calculations bulk solids handling Vol. 29 (2009) No. 8, pp. 454−457

Belt Feeders MEKA CrushingScreening Plants

Belt feeder design thus needs to consider all specific requirements determined by the material being moved, as well as capacity and geometry. The rugged design and features such as robust heavy-duty idlers,

Hybrid Apron Belt (HAB) Feeder

The HAB Feeder’s hybrid design combines both belt and apron feeder technology, utilising conventional conveyor belting bolted to the aprons, for a power-efficient and high-tonnage-capacity feeder. The reinforced

Belt Feeder Don Valley Engineering Belt Feeders

Belt Feeders Horizontal and Inclined Belt Feeders are predominantly used for extracting bulk materials from bunkers, hoppers and stock piles or for regulating feeds to screens, conveyors and crushers. They provide

How to Design Efficient and Reliable Feeders for Bulk Solids

There are two basic types of feeders used in industrial plants: volumetric and gravimetric. As its name implies, a volumetric feeder modulates and controls the volumetric rate of discharge from a bin (e.g., cu. ft./hr.). The four most common types of such feeders are screw, belt, rotary valve, and vibrating pan. A gravimetric feeder, on the

Sidewinder Conveyor Design Software Sidewinder

This design philosophy ensures that many conditions which may have otherwise gone unchecked are accounted for in the design phase. For example, belt liftoff is automatically calculated using a “worn” belt mass

Belt Feeders Bulk Material Transport

Belt Feeders utilize a flat belt and are flood-loaded in the inlet area. The bulk material is metered through an adjustable strike-off plate. The inlet area is completely enclosed with skirting to prevent spillage. Metering capacities up to 20,000 cubic feet per hour can easily be handled with Kase Belt Feeders.

Bulk solids handlingEngineering Feeder and Conveyor Design

Belt feeder calculations require knowledge of the consolidated silo or bin opening pressure for initial bin fill condition, as well as flow condition. Design techniques such as tapered openings by 5 degrees divergence, and relieving the feeder angle by a few degrees, assists with minimising pull-out torques.

FIAP Belt Feeders Aquatic EquipmentDesign Inc.

We offer FIAP Belt Feeder Standard in two different sizes (hold capacity of 3 and 5 kg) and with two different run times (12 and 24 hours). FIAP Belt Feeder Standard is most suitable for feeding spawn and fry and allows for dosing buffering agents and pharmaceuticals. Casing and cover feature excellent weather resistance properties and long

Design of a Material Handling Equipment: Belt

2014年1月16日The design of belt conveyor system using three-rolls idlers, in terms of length, size, speed, capacity, roller diameter, idler spacing, power and tension, type of drive unit, location and...

Belt Feeder Design: Starting Load Calculations bulk-online

2018年9月18日Belt Feeder Design: Starting Load Calculations (A.E. Maton) | | A.E. Maton, Australia Belt Feeder Design: Starting Load Calculations bulk solids handling

Reliable belt feeder to extract materials I

Modular design. Our Belt Feeders combine efficiency and robustness with modular design. High capacity models are also available for busy companies with higher levels of mass flow. The option of rail-mounted

Belt Feeders WÖHWA Pfedelbach, Germany

The use of WÖHWA belt feeders is a safe method for the reclaim of poorly flowing bulk materials (e.g. sand) or for small blending or loadout quantities. Desired percentages in blends can be achieved by using frequency converters for variable belt speeds. Standard reclaim/feed quantities of 3 to 1000 t/h can be achieved dependant upon belt

How feeder design impacts silo discharge Processing Magazine

2022年12月20日A feeder must work in unison with the silo to ensure reliable flow. Screw, belt and rotary valve feeders are commonly used to maintain mass flow. Screw and belt feeders are typically used to control discharge from slotted or wedge-type hoppers (Figure 2, left) but can also be used to control discharge from conical hoppers (Figure 2, right).

Helix Website FeederCalcs

Belt Feeder Calculation Procedure in Helix delta-T6 Build a model of the conveyor Go to Calcs, Feeder Calculations and enter the hopper dimensions and material properties Press Calculate Transfer the Feeder Flowing Horizontal Resistance Force Ff to the Conveyor Sections, Tension Adjustment column.