Erengy Saving Used In Mine Bearing Ball Mill

SKF Energy Efficient deep groove ball bearings with

To determine the energy eficiency of S E deep groove ball bearings vs. conventional bearings, a European conveyor manufacturer conducted a roll resistance test according to speciication. he E tested bearings on conveyor idler rollers euipped with conven-tional

A switch from ball mills to Vertimill® boosts Miaogou

2016年3月30日The mine’s original grinding circuit consisted of ball mills exclusively. The primary stage comprised 5 ball mills, the secondary stage 3 ball mills, and the final, tertiary stage 2 ball mills. The original tertiary

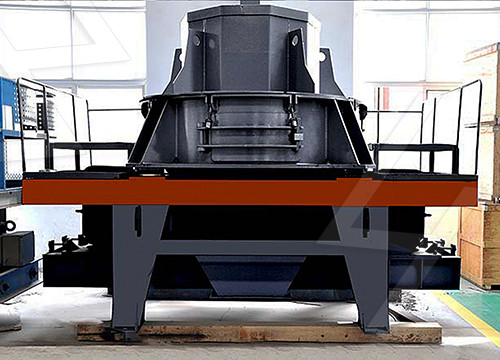

Mining ball mill-Baichy Machinery

Ball mill, also called grinding mill, ball grinding mill, is the key equipment to grind crushed materials into fine powder 20-75 micrometer. It has grate type and overflow type. ≤25mm Feed Size. 18.5-800KW Motor Power.

Energy efficient bearing and steel ball SKF

Bearing interfaces . Bearing execution . Sealing, mounting and dismounting . Bearing selection examples . Vibrating screen . Rope sheave . Centrifugal pump . Supporting

Trunnion Bearing Assembly Ball MillRod Mill

2015年7月28日There is a hole in the middle of the bearing seat to allow the oil from the oil line to come out of. Radiating away from this hole

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the Steel

erengy saving used in mine bearing ball mill machineto

Buy erengy saving used in mine bearing ball mill from Machine Business Opportunities, erengy saving used in mine bearing ball mill specifications: ball mill, 1. high

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size

Energy Saving Tube/ Clinker Gold Mine Ball Mill Price

Scope: Tube mill is used in cement production to grind various materials that include air-scanning mill system for raw materials grinding in a new and dry cement production line, end-discharging and lifting circulating mill

Ball mills used in program Start Your Own Gold Mine

Rudimentary ball mill startup. This is classic Tanzanian rudimentary ball mill. It contains balls, it is run on diesel engine, it runs in dry mode. We will certainly convert it to wet and water mode, to demonstrate faster

SKF Energy Efficient deep groove ball bearings

SKF Energy Efficient (E2) deep groove ball bearings can provide more than twice the service life while reducing energy use and total cost of ownership. Design improve-ments reduce frictional losses in the bearing by at least 30% when compared to the same size SKF Explorer bearing. This results in energy savings over the life of the application.

SKF Energy Efficient deep groove ball bearings with shields

To determine the energy eficiency of S E deep groove ball bearings vs. conventional bearings, a European conveyor manufacturer conducted a roll resistance test according to speciication. he E tested bearings on conveyor idler rollers euipped with conven-tional bearings, and euipped with S E bearings. s diagram 1 illustrates,

A switch from ball mills to Vertimill® boosts Miaogou

2016年3月30日The mine’s original grinding circuit consisted of ball mills exclusively. The primary stage comprised 5 ball mills, the secondary stage 3 ball mills, and the final, tertiary stage 2 ball mills. The original tertiary

Mining ball mill-Baichy Machinery

ball mill adopts rolling bearing support instead of sliding bearing support with bearing bush to save energy by 10-20%. Product features High processing capacity,obvious continuous operation advantages. Working

Grinding Mills Mineral Processing Equipment CITIC

For over 60 years, CITIC Heavy Industries (CITIC HIC) has focused on providing global customers with reliable, energy-saving and high-efficiency mineral grinding equipment relying on its advantages of technological

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size

Energy Saving Tube/ Clinker Gold Mine Ball Mill Price

Scope: Tube mill is used in cement production to grind various materials that include air-scanning mill system for raw materials grinding in a new and dry cement production line, end-discharging and lifting circulating mill

Wafangdian Mine Bearing Manufacture Co., Ltd

Address: No. 56 North Section Beigongji Street Wafangdian City, Dalian, Liaoning, China Telephone: Zip Code: Fax: Please sign in to view contact details Account Registered in: 2011 Business Range: Industrial EquipmentComponents Business Type: Manufacturer/Factory, Trading Company Main Products:

sbm/sbm energy saving ball mill with good quality bearing

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Ball grinding mill

The Ball Millis used to grind many kinds of mine and other materials, or to selectthe mine. Ball mill is widely used in building material, chemicalindustry, etc. There are two ways of grinding: the dry way and the wetway. It can be divided into tabular type and flowing type according todifferent expelling mine. Energy-saving .4.5 KW motor

SAG Mill Grinding Circuit Design Mineral

2016年6月6日These mills typically grind ROM ore in a single stage. A large example of such a mill was converted from a single-stage milling application to a semi autogenous ball-mill-crushing circuit, and the

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日The energy consumption is 2.5–3.5 kWh/t and about 10 kWh/t when recycling of the material is used. The comminution efficiency of a HPGR is better than ball mills such that it consumes 30–50 % of the specific energy as compared to a ball mill.

Ball Mill RETSCH powerful grinding and homogenization

The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. CoolingHeating Mixer Mill MM 500 control Material feed size*: <= 10 mm Final fineness*: ~ 0.1 µm Vibrational frequency: 3 30 Hz (180 -1800 min-1) Product details Nanoscale Grinding

Ball Mill mpl Ultrafine Powder Technology

Bearing: The bearing is the supporting part of the ball mill, which carries the mass of the rotating part of the ball mill and the impact load of the grinding medium. Moreover, the rolling bearing is used instead of the sliding bearing, which has low running resistance and significant energy saving.

SKF Energy Efficient deep groove ball bearings

SKF Energy Efficient (E2) deep groove ball bearings can provide more than twice the service life while reducing energy use and total cost of ownership. Design improve-ments reduce frictional losses in the bearing by at least 30% when compared to the same size SKF Explorer bearing. This results in energy savings over the life of the application.

SKF Energy Efficient deep groove ball bearings with shields

To determine the energy eficiency of S E deep groove ball bearings vs. conventional bearings, a European conveyor manufacturer conducted a roll resistance test according to speciication. he E tested bearings on conveyor idler rollers euipped with conven-tional bearings, and euipped with S E bearings. s diagram 1 illustrates,

A switch from ball mills to Vertimill® boosts Miaogou

2016年3月30日The mine’s original grinding circuit consisted of ball mills exclusively. The primary stage comprised 5 ball mills, the secondary stage 3 ball mills, and the final, tertiary stage 2 ball mills. The original tertiary

Energy-Saving Electric Drives with Reduced-Friction Bearings

2012年11月5日Electric motors that comply with the highest current efficiency class IE3 are often fitted with special, reduced-friction bearings which help the drive systems to operate in an energy-saving way. Developing energy-efficient deep-groove ball bearings NSK has already developed such bearings for numerous manufacturers and users of

Energy-Efficient Technologies in Cement Grinding

2016年10月5日The energy consumption is 2.5–3.5 kWh/t and about 10 kWh/t when recycling of the material is used. The comminution efficiency of a HPGR is better than ball mills such that it consumes 30–50 % of the

SAG Mill Grinding Circuit Design Mineral

2016年6月6日AG mills (or SAG mills with low ball charges) are often used in single-stage grinding applications. Based on their higher throughput and coarser grind relative to AG mills, it is more common for SAG mills

Ball grinding mill

The Ball Millis used to grind many kinds of mine and other materials, or to selectthe mine. Ball mill is widely used in building material, chemicalindustry, etc. There are two ways of grinding: the dry way and the wetway. It can be divided into tabular type and flowing type according todifferent expelling mine. Energy-saving .4.5 KW motor

sbm/sbm energy saving ball mill with good quality bearing

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Mining ball mill-Baichy Machinery

ball mill adopts rolling bearing support instead of sliding bearing support with bearing bush to save energy by 10-20%. Product features High processing capacity,obvious continuous operation advantages. Working

Used Ball Mills for sale in USA Machinio

36" Dia. Paul O. Abbe Inc. Rubber lined Ball Mill. USED. Manufacturer: Paul O. Abbe. S/N A46311. Rubber lined drum, inside dimensions: 36"øx 42". Side-mounted 6" x 9" locking hatch with counter weight on shell. Max allowable working temperature for drum and jacket = 200°f. Carbon steel shell $8,500 USD.

03 Ball Mills PDF Mill (Grinding) Bearing (Mechanical) Scribd

Ball mills. Michael Müller-Pfeiffer Research Institute of the Cement Industry (Düsseldorf) Seminar Grasim, 28 February 2007 Structure. 1. Introduction 2. Movement of grinding media in a tube mill 3. Ball charge and ball filling level 4. Components of ball mills (linings, diaphragms, mill inlet, drive, bearing) 5. Mill ventilation, water injection and grinding aids 6.

Metso Outotec to deliver large energy-efficient grinding mills to

2022年12月16日“The PremierTM semi-autogenous (SAG) mill to be delivered to the Kiaka project is one of the largest gear-driven grinding mills in the world with its 18 MW of installed power. The PremierTM ball mill has been designed to pair smoothly with the SAG mill.

mill/sbm comparing two bearing operating costs of ball mill.md

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long. 1 Commit. 1 Branch. 0 Tags mill / sbm comparing two bearing o...

Ball Mill mpl Ultrafine Powder Technology

Bearing: The bearing is the supporting part of the ball mill, which carries the mass of the rotating part of the ball mill and the impact load of the grinding medium. Moreover, the rolling bearing is used instead of the sliding bearing, which has low running resistance and significant energy saving.