Silica Sand Grinding And Milling

Evolution of grinding energy and particle size during dry ball

2020年10月1日In this work, we used a commercial silica sand composed of 98.60% of pure silica for filtration applications, marketed by Euromortier. It is a sieved sand

The Effect of Milling Time on the Size of Silica Particles

2018年3月1日Silica sand was milled by High Energy Milling in order to reduce the size into powder form. Effect of milling time shown the content of sodium and silicon is

Preparation Of Nanoparticle Silica From Silica Sand and

2012年9月12日After the grinding/milling processes, an aggregation of fine particles (<10 µm) can be observed, and the population of

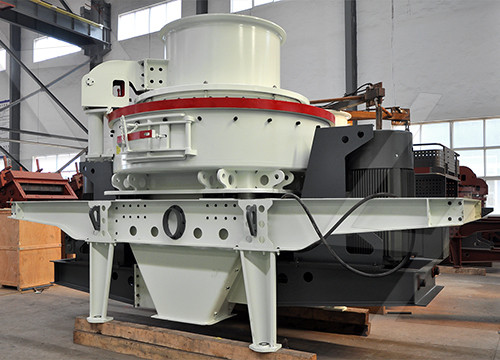

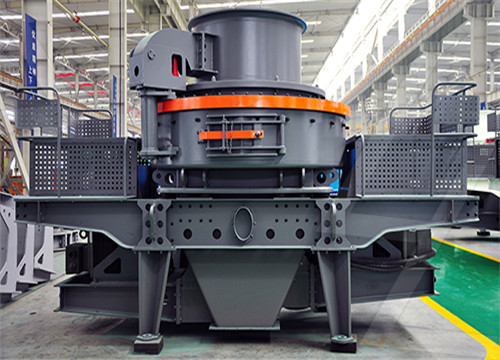

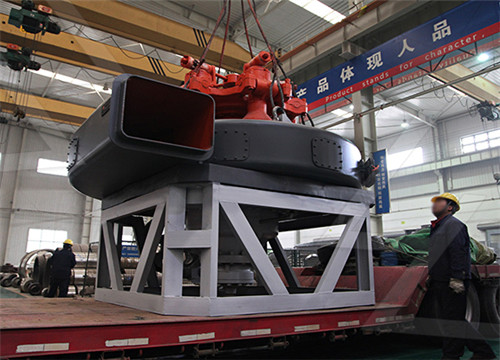

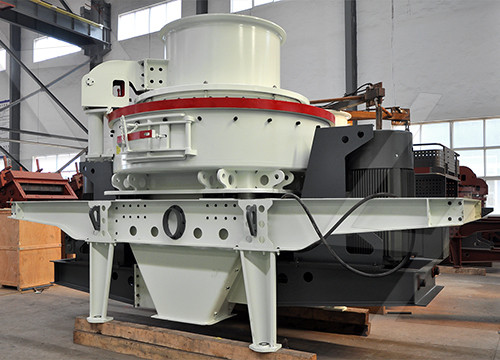

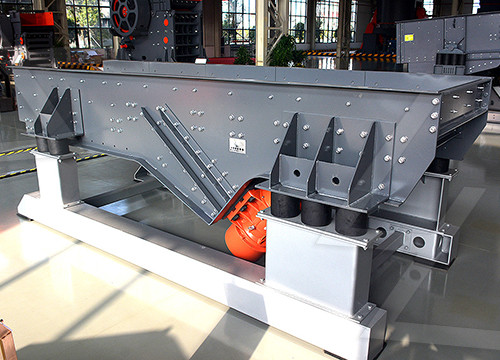

WetDry Silica Sand Ball Mill for Silica Sand Grinding

Silica sand ball mill is a professional ball mill equipment for grinding silica sand. In some areas, it is also called silica sand grinding mill or silica sand grinding machine. Silica sand is a chemically stable silicate

What kind of silica sand grinding mill is best? gkmill

2023年1月12日Due to the combination of drying and grinding, the silica sand vertical roller mill has low cost, low humidity, low energy consumption, and adjustable fineness.

grinding mill for silica sand YouTube

ChatNow: https://wa.me/Contact: https://mpl-mineral/contact/Email: contact@mpl-mineralMore About grinding mill for

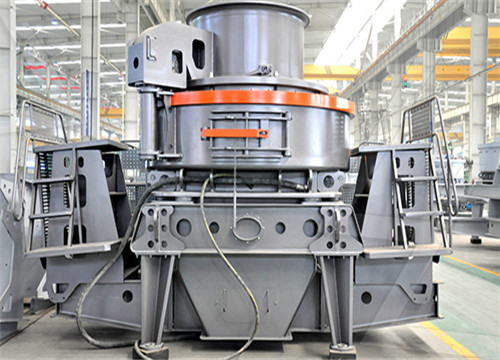

Silica Sand Grinding Mill Ultrafine Grinder

The silica sand vertical mill machine complies with all the current safety standards. All hazardous operations are provided with multiple protection. All safety functions are

Silica, Crystalline Overview Occupational Safety and

Overview. Crystalline silica is a common mineral found in the earth's crust. Materials like sand, stone, concrete, and mortar contain crystalline silica. It is also used to make

Effect of ball and feed particle size distribution on the milling

2018年6月1日Mass fraction M3 vs. milling time for various grinding times at a media fill level of J = 20% (a) feed size = -1700 + 850 μm (b) feed size = -1 180 + 850 μm. A fundamental investigation on the breakage of a bed of silica sand particles: an attainable region approach. Powder Technol., 301 (2016), pp. 1208-1212. Article. Download PDF

Comparative Study on Improving the Ball Mill Process Parameters

2021年2月19日The milling process factors influencing the particle size include grinding time, milling speed, the size of the balls and balls to powder weight ratio. So far many studies have concentrated on the synthesis of ultrafine silica sand production, however not on the process parameters optimization study [ 10 ].

The Effect of Milling Time on the Size of Silica Particles from Silica Sand

2018年3月1日Silica sand was milled by High Energy Milling in order to reduce the size into powder form. Effect of milling time shown the content of sodium and silicon is increased in sodium silicate...

(PDF) Process Parameters Optimization of Silica

2014年2月26日Process Parameters Optimization of Silica Sand Nanoparticles Production Using Low Speed Ball Milling Method February 2014 Chinese Journal of Engineering 2014(8):1-4

Preparation Of Nanoparticle Silica From Silica Sand and

To increase levels of SiO2 in silica sand and quartzite conducted leaching with sulfuric acid at room temperature with a variation of the concentration of sulfuric acid to the sample. Synthesis of nano-silica performed by means of grinding PBM (planetary ball mill) with a variation of milling time 10-60 hours.

grinding mill for silica sand YouTube

ChatNow: https://wa.me/Contact: https://mpl-mineral/contact/Email: contact@mpl-mineralMore About grinding mill for silica sand...

What kind of silica sand grinding mill is best? gkmill

2023年1月12日Due to the combination of drying and grinding, the silica sand vertical roller mill has low cost, low humidity, low energy consumption, and adjustable fineness. The content of fine silica powder above 325 mesh can be controlled at about 3%, which can better meet the requirements of the football team’s fine silica powder.

Parameter Optimization of Ball Milling Process for Silica Sand

2018年10月25日The three main parameters applied in this study are Ball to Powder weight Ratio (BPR), time milling process, and rotational speed (rpm). The materials used in the study was Bangka silica sand tailing, with an average size of D50: 267 µm, based on the measurement of Particle Size Analyzer (PSA). The results of signal-to-noise analysis

Silica Sand Grinding Mill Ultrafine Grinder

The silica sand vertical mill machine complies with all the current safety standards. All hazardous operations are provided with multiple protection. All safety functions are hardwired in the control cabinet of the vertical mill. The optimized grinding action reduces the noise of the machine to a low level of max.

Process Parameters Optimization of Silica Sand Nanoparticles Hindawi

2013年10月7日The grinding jars are arranged eccentrically on sun wheel of planetary ball mill. Grinding balls in grinding jars are subjected to superimposed rotational movements, known as the Coriolis forces. After 10 hours of milling, the silica sand was analyzed using Malvern Instruments Mastersizer 2000 particle size analyzer for particle size and

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers

Grinding Mill, Grinding Mill direct from Henan mpl Heavy

Factory Flour Silica Sand Grinding Raymond Pulverizers Powder Stone Mill Grinders. $50,000.00 $65,000.00 / set. 1 set Coal Powder Vertical Roller Mill Stone Silica Sand Grinding Mill Machines. $70,000.00 $885,000.00 / set. 1 set (Min. Order) Cement Grinding Mill Ultra Fine Particle 100tp Cement Mill.

What Are The Requirements For Pellet Refined Silicon? What Kind

2023年1月11日If you have a need for tar residue treatment or need to purchase a silica sand grinding mill, p lease contact mkt@hcmilling or call at +86-773-, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check hcmilling. And Support

Learn About Silicosis American Lung Association

2022年11月17日So, any occupation that involves chipping, cutting, drilling, or grinding soil, granite, slate, sandstone, or other natural material can cause exposure to silica dust. Some high-risk occupations are: Construction work, including jackhammering, rock drilling and chipping, tunneling, sandblasting, asphalt milling and cutting concrete and brick

Silica sand processing plant equipment Metso Outotec

The production process for silica sand consists of crushing, grinding, sizing, beneficiation, dewatering and drying. Metso Outotec can supply complete flowsheets using its own equipment and that of partners. Our planet positive portfolio helps reduce energy consumption and emissions, improve water efficiency, supports circularity and is

Parameter Optimization of Ball Milling Process for Silica Sand

2018年10月25日The three main parameters applied in this study are Ball to Powder weight Ratio (BPR), time milling process, and rotational speed (rpm). The materials used in the study was Bangka silica sand tailing, with an average size of D50: 267 µm, based on the measurement of Particle Size Analyzer (PSA). The results of signal-to-noise analysis

(PDF) Process Parameters Optimization of Silica

2014年2月26日Process Parameters Optimization of Silica Sand Nanoparticles Production Using Low Speed Ball Milling Method February 2014 Chinese Journal of Engineering 2014(8):1-4

Research Article Process Parameters Optimization of Silica

Process Parameters Optimization of Silica Sand Nanoparticles Production Using Low Speed Ball Milling Method ZulkhairiRizlanandOthmanMamat Department of Mechanical Engineering, Universiti Teknologi P ETRONAS, Bandar Seri Iskandar, Tronoh, Perak, Malaysia eccentrically on sun wheel of planetary ball mill. Grinding

-Design of experiments for dry ball milling of silica sand samples

Grinding process can be modeled by matrix, kinetic and energy models that breakage rate should be concerned for the matrix and kinetics modeling. Generally, breakage rate depends on the material...

Preparation Of Nanoparticle Silica From Silica Sand and

To increase levels of SiO2 in silica sand and quartzite conducted leaching with sulfuric acid at room temperature with a variation of the concentration of sulfuric acid to the sample. Synthesis of nano-silica performed by means of grinding PBM (planetary ball mill) with a variation of milling time 10-60 hours.

grinding mill for silica sand YouTube

ChatNow: https://wa.me/Contact: https://mpl-mineral/contact/Email: contact@mpl-mineralMore About grinding mill for silica sand...

Silica Sand Grinding Mill Ultrafine Grinder

The silica sand vertical mill machine complies with all the current safety standards. All hazardous operations are provided with multiple protection. All safety functions are hardwired in the control cabinet of the vertical mill. The optimized grinding action reduces the noise of the machine to a low level of max.

Grinding mill machine, mineral mill, raymond mill,

Applications Common required sizes are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh Quartz has high fire resistance. In the industry, silica sand is often

silica rock sand grinding mill machine,SiO2 grinding mill

silica rock sand grinding mill machine(325-2500 mesh)Professional crusher and grinding mill manufacturer and supplier. Tell your raw material and the target

Sand making equipment Wet Ball milling machine for various

Quality Sand making equipment Wet Ball milling machine for various stones find quality Ball grinding machine, Mine MillBall grinding machine from Zhengzhou Yinhai Mining Machinery Equipment Co., Ltd. of China Suppliers .

Process Parameters Optimization of Silica Sand Nanoparticles Hindawi

2013年10月7日The meshing and drying process are repeated every 2 hours of milling until the total milling time has reached 10 hours. The mesh sizes used were 425 μ m, 212 μ m, 150 μ m, and 63 μ m. After 10 hours of milling, the silica sand was analyzed using Malvern Instruments Mastersizer 2000 particle size analyzer for particle size and size

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers

Grinding Mill, Grinding Mill direct from Henan mpl Heavy

Factory Flour Silica Sand Grinding Raymond Pulverizers Powder Stone Mill Grinders. $50,000.00 $65,000.00 / set. 1 set Coal Powder Vertical Roller Mill Stone Silica Sand Grinding Mill Machines. $70,000.00 $885,000.00 / set. 1 set (Min. Order) Cement Grinding Mill Ultra Fine Particle 100tp Cement Mill.