Calculation Crushing Equipment Plant

Crusher Efficiency Calculations Mineral Processing

19 行2014年9月15日Considering a 30-in. diameter roll crusher the maximum size particle that can be nipped with the roll crusher set at 1

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour

CRUSHING PLANT PERFORMANCE EVALUATION USING OEE

2.1 OEE Calculation for Crushing Plant . Crushing plants are used in granite aggregate quarries for processing and classifying crushed granite materials. Abuja market for

Mineral Processing Plant Design University of

Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in

Cost Analysis for Crushing and Screening Part II CORE

model earlier developed by Heyman and Lindström in order to calculate the cost per metric ton within the world of crushing and screening. By implementing the cost calculation in

11.19.1 Sand And Gravel Processing US EPA

undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined

crusher design calculation Crushing and Screening Plant

Crushing Plant Design and Layout Considerations. 3 Table 2 Production Requirements Typical Example: 60” x 89” primary crushermill feed conveyor system Operating

Understanding Soybean Crush CME Group

2023年3月8日In a crush spread, the trader takes a long position in Soybean futures against short positions in Soybean Meal and Soybean Oil futures. This is also known as the board crush. The value of the crush

Aggregate Processing Plant Design Calculation Crusher Mills

If you are looking for Aggregate crushing process plant you or use our Budget Calculator to determine aggregate processing plant design calculation grinding

Aggregates Industry Equipment Manufacturer Superior Industries

Texas Aggregate Producer Benefits From Dealer/Manufacturer Partnership. Using a combination of Superior’s crushing, screening and washing equipment, Central Texas

Home Page NIAflow

Three stage lime stone crushing plant set up in three individual plants. Secondary and tertiary plant featuring closed crushing circuits. Calculate material flow through processing machinery in wet or dry

11.19.2 Crushed Stone Processing and Pulverized Mineral

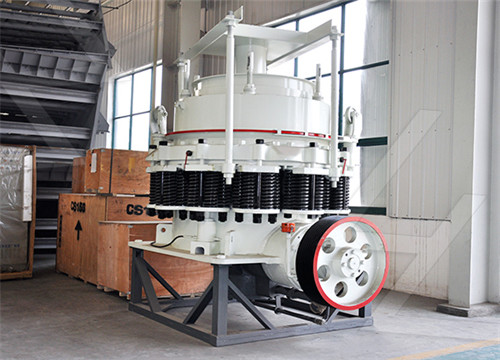

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to 1 inch), is returned to the sizing screen.

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest. The power consumption of a machine or installation is usually expressed in kw.-hours per ton as being the most convenient method.

Cost Analysis for Crushing and Screening Part II CORE

model earlier developed by Heyman and Lindström in order to calculate the cost per metric ton within the world of crushing and screening. By implementing the cost calculation in Microsoft excel it would be more user friendly and applicable when calculating the cost in crushing and screening.

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained, which means that we must provide secondary crushing capacity to take care of 57 tons for each 100 tons fed to the primary crusher.

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

crushing force required to crush the material and as the piston reciprocates inside the bin onto which the materials are placed or fall one by one with the help of a hopper gets crushed and acquires the shape of the bin [6]. This crushed material can now be removed from the bin from the bottom part by removing the base plate of the bin and

Crusher Aggregate Equipment For Sale MachineryTrader

2023年3月9日TractorEquipment Company. Birmingham, Alabama 35202. Phone: (205) 708-7059. Email Seller Video Chat. Adding to “Used Equipment” inventory, this low hour mpl Cone Crusher, Year 2020 Hours 945 Located Forest Park, GA Sales Price $650,000.00 Unit clean and in excellent condition, Get Shipping Quotes.

Understanding Soybean Crush CME Group

2023年3月8日In a crush spread, the trader takes a long position in Soybean futures against short positions in Soybean Meal and Soybean Oil futures. This is also known as the board crush. The value of the crush equals the Soybean Oil futures price plus the Soybean Meal futures price, minus the price of Soybean futures.

Soybean Processing Crown Iron Works

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the equipment.

ball mill calculation MiningQuarry Plant

2013年3月20日As a leading global manufacturer of crushing and milling equipment,mpl is professional mineral processing ball mill load calculations Crusher South Africa. ball mill design calculation Grinding Plant.

calculation in marble mining MiningQuarry Plant

2013年8月28日SAMPLE CALCULATION: 1. Determine the volume you require: Multiply (LENGTH in FEET) x (WIDTH in FEET) x . Marble Crushers, Marble mining, .

Henan Mining Machinery and Equipment Manufacturer Calculation

Calculation Vibration Conveyor Xls Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Belt conveyors principles for calculation and design free download. Post at: 27 May 2012

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

水泥厂破碎机润滑改良,轴承温度下降3-4℃,优润(U.LUBE)高负载轴承脂 Cement plant crusher

Crusher is a common equipment in cement plant, used for raw material crushing. Lubrication working conditions both high-speed, and heavy load, strong impact, but also by the dust, outdoor moisture color ring, working conditions are harsh. Poor lubrication will seriously affects the equipment running performance, and even eventually affect the

Home Page NIAflow

NIAflow is a simulation software for all kinds of mineral processing applications. With its intuitive graphical interface it can model and calculate entire plants. NIAflow supports dry and wet crushing, screening and

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour crushing day are easy to calculate. The figures must be regarded only

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained, which means that we must provide secondary

(PDF) Justification, Selection and Calculation of

2019年2月1日T he excavator loads the reloadinginto the crushing plant's bunker, then the reloadingfrom the bunker enters the plate conve yor, and from there, through the feed bun ker, into the two-roll crusher.

Crusher Aggregate Equipment For Sale

2023年3月9日TractorEquipment Company. Birmingham, Alabama 35202. Phone: (205) 708-7059. Email Seller Video Chat. Adding to “Used Equipment” inventory, this low hour mpl Cone Crusher, Year

Soybean Processing Crown Iron Works

The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run

velocity calculation in cement mill MiningQuarry Plant

2013年3月19日Philippines 150TPH Riverstone Crushing Plant; Indonesia 180 tph Iron Ore crushing plant; How Much VSI Sand Crusher; How much the ball mill and capacity? Four in one type mobile crusher used in Kenya; Limestone TGM130X Grinding mill in Egypt; Saudi Arabia Dolomite Grinding Mill; Categories. Beneficiation Plant; Crushing Plant;

ball mill calculation MiningQuarry Plant

2013年3月20日As a leading global manufacturer of crushing and milling equipment,mpl is professional mineral processing ball mill load calculations Crusher South Africa. ball mill design calculation Grinding Plant.

Henan Mining Machinery and Equipment Manufacturer Calculation

Calculation Vibration Conveyor Xls Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Belt conveyors principles for calculation and design free download. Post at: 27 May 2012

Henan Mining Machinery and Equipment Manufacturer Ball Mill

Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. ball mill sizing calculation Crushing Plant,Grinding Mill. Ball mill rpm calculation on size. Gulin supply Mining and construction

Screening/Sizing McLanahan

McLanahan offers a variety of screening solutions for both wet and dry applications to fit the needs of producers in many industries. Learn more about McLanahan’s screening solutions on the individual product pages.

FUEL CONSUMPTION OF CONSTRUCTION EQUIPMENT LinkedIn

2020年2月18日According to the calculation = K * KW / KPL = 0.226 *129.6 / 0.85 = 34.45 LPH (at full rated output of engine and full load) If machine performs in 40 to 60% load as standard = 34.45 * 40% =...

3. CALCULATION OF MACHINE RATES Food and Agriculture

For equipment that works very few hours per day, the derived equipment lives may be very long and local conditions should be checked for the reasonableness of the estimate. 3.3.3 Salvage Value (S) This is defined as the price that equipment can be sold for at the time of its disposal. Used equipment rates vary widely throughout the world.

A review of modeling and control strategies for cone crushers

2021年8月15日Cone crushers, which are present in secondary or tertiary crushing circuits, usually have minimal control over the feed rate and properties (hardness, moisture content, particle size distribution, and amount of mixed ores). These values are often defined by upstream processes.