Hardfacing Vertical Mills

In-situ hard facing services for vertical roller mills

Whether it’s lower grinding efficiency, higher energy costs or increased risk of equipment damage, excessive wear of your vertical roller mill (VRM) means trouble. But with our in-situ hard facing services, you can keep

Cement Industry ? Engineered hardfacing solutions to

At Hardcarb, we have developed a comprehensive refurbishment procedure for Vertical Mills (VRM’s) which includes advanced automated welding equipment, high performance

Vertical mills Welding Alloys

SOLUTIONS FOR VERTICAL MILLS. From the monitoring of wear to predicting and pre-defining areas that need hardfacing, then carrying out the repairs before returning the

OK vertical roller mill d3pcsg2wjq9izr.cloudfront.net

- OK vertical roller mills use 30-50% less energy than ball mill systems Simple layout and fewer machines in the mill circuit ensure high run-factor and like slag, hardfacing is

HardfacingRebuilding Ecorporates

Hardfacing, also known as hard surfacing, is the application of buildup or wear-resistant weld metals to a part's surface by means of welding or joining. Most worn parts don't fail from a single mode of wear, such as

Hardfacing a Vertical Mill Roller YouTube

2017年1月25日Hardfacing a Vertical Mill Roller 4,521 views Jan 25, 2017 49 Dislike Nael 4.01K subscribers The background music of the first 35 seconds of this video has

Hardfacing Table Liners of Vertical Roller Mills bulk

2006年8月22日Hard facing of Vertical Rollers The liners can be hard faced one by workhardening types of electrodes where the hardness go on increasing while it is in

Hardfacing Products Lincoln Electric

Hardfacing products are available for restoring parts to their original size that have been worn down due to metal-to-metal friction, severe impact, severe abrasion or abrasion

JUNGWON Vertical Roller Mill, Roller Press and

Hardness varies from 55 to 67 HRC and temperature application up to maximum 850 °C. Can be used for vertical mill body liner, classifier blade, cooler EP hot gas duct, liner for clinker crusher hammer casing, inlet

Hardfacing a Roller Mill discuss in this session Typical

2023年2月24日ما عليك سوى الانتساب إلى هذه القناة للاستفادة من المزايا:https://youtube/channel/UCnBpfQliNMKSmnqOBr2DRIQ

Key Industry Program Castolin Eutectic

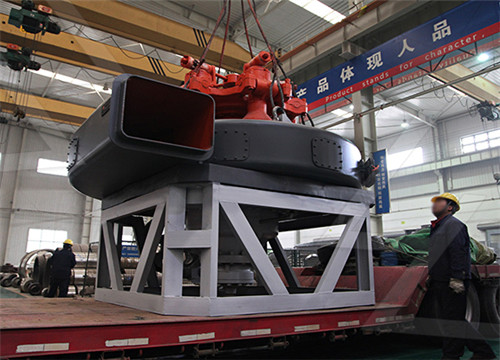

In the 1970s, Vertical Roller Mills (VRMs) became increasingly dominant for grinding raw materials, mainly for the cement and power industries, due to their high energy efficiency and excellent drying capacity. The VRM’s function is to crush the materials into very fine particles, just prior to being stored or after the primary crushers.

Hardfacing alloy selector ? Hardcarb Technologies

Dredge and dragline bucket lips and teeth, hammers, ripper teeth, agitator blades, wear plates, screens in the coal industry, exhaust fans, top coats on pulverizor rolls in vertical mills, etc. High C-Cr-Nb-W alloy for hardfacing against very high mineral wear and erosion. The weld deposit has a large percentage of hypereutectic carbides.

Vertical Mill table hardfacing YouTube

2018年10月15日Hardfacing of spare Mill Table segment of Vertical mill. We used a CNC technology and our designed Hardfacing welding wires (HH-810 with the welded hardness

Frequently asked questions about hardfacing The Fabricator

2005年3月8日Hardfacing, also known as hardsurfacing, is the application of buildup or wear-resistant weld metals to a part's surface by means of welding or joining. 2. What base metals can be hardfaced? Carbon and low-alloy steels with carbon contents of less than 1 percent can be hardfaced. High-carbon alloys may require a special buffer layer.

OK vertical roller mill d3pcsg2wjq9izr.cloudfront.net

- OK vertical roller mills use 30-50% less energy than ball mill systems Simple layout and fewer machines in the mill circuit ensure high run-factor and like slag, hardfacing is an interesting and viable means of achieving a high availability of the grinding system, optimising the grinding process and

sbm/sbm hardfacing vertical mills.md at main dihog/sbm

Contribute to dihog/sbm development by creating an account on GitHub.

HardfacingRebuilding Ecorporates

Hardfacing, also known as hard surfacing, is the application of buildup or wear-resistant weld metals to a part's surface by means of welding or joining. Most worn parts don't fail from a single mode of wear, such as

Hardfacing Products Lincoln Electric

hardfacing Hardfacing products are available for restoring parts to their original size that have been worn down due to metal-to-metal friction, severe impact, severe abrasion or abrasion plus impact. Hardfacing products can also be used for overlay to add a protective layer to carbon steel surfaces. Alloy Resources Welding Consumables Packaging

WA Applications Welding Alloys

WA Hardfacing Vertical Grinding Mills and Ball Race Mills • Supply of new preventively hardfaced advanced grinding components • Hardfacing of worn castings back to the original component profile • Refurbishment grinding of components within the local Integra Service Centre or in-situ

Hardfacing a Roller Mill discuss in this session Typical Questions

2023年2月24日ما عليك سوى الانتساب إلى هذه القناة للاستفادة من المزايا:https://youtube/channel/UCnBpfQliNMKSmnqOBr2DRIQ

Hi-Chrome Wear Segments for vertical roller mills

Segments are suitable for repeated hardfacing and can be refurbished in-situ to bring them back to the correct surface profile. This keeps downtime to minimum and ensures the continued high performance of your vertical roller mill. Hi-Chrome Wear Segments can also be reversed and re-welded on some applications of the rollers

id/hardfacing of vertical cement mill.md at main lqdid/id

Contribute to lqdid/id development by creating an account on GitHub.

JUNGWON Vertical Roller Mill, Roller Press and Hardfacing

Hardness varies from 55 to 67 HRC and temperature application up to maximum 850 °C. Can be used for vertical mill body liner, classifier blade, cooler EP hot gas duct, liner for clinker crusher hammer casing, inlet chute of ball mill, liner of process fan casing and many more application in cement and mining.

Jual Hardfacing Vertical Roller Mill Harga Terbaru PT. Budi

Budi Mandiri Karunia Jual Hardfacing Vertical Roller Mill Harga Terbaru, TerlengkapTerpercaya. Dapatkan Produknya, Cek Sekarang Juga! Skip to content. Top Bar. Call: Email: budimandirikarunia@gmail Primary Menu. Home; About Us; Product and Service. Welding Machines Control;

Key Industry Program Castolin Eutectic

In the 1970s, Vertical Roller Mills (VRMs) became increasingly dominant for grinding raw materials, mainly for the cement and power industries, due to their high energy efficiency and excellent drying capacity. The VRM’s function is to crush the materials into very fine particles, just prior to being stored or after the primary crushers.

Vertical Mill table hardfacing YouTube

2018年10月15日Hardfacing of spare Mill Table segment of Vertical mill. We used a CNC technology and our designed Hardfacing welding wires (HH-810 with the welded hardness

Hardfacing alloy selector ? Hardcarb Technologies

Dredge and dragline bucket lips and teeth, hammers, ripper teeth, agitator blades, wear plates, screens in the coal industry, exhaust fans, top coats on pulverizor rolls in vertical mills, etc. High C-Cr-Nb-W alloy for hardfacing against very high mineral wear and erosion. The weld deposit has a large percentage of hypereutectic carbides.

WA Applications Welding Alloys

WA Hardfacing Vertical Grinding Mills and Ball Race Mills • Supply of new preventively hardfaced advanced grinding components • Hardfacing of worn castings back to the original component profile • Refurbishment grinding of components within the local Integra Service Centre or in-situ

JUNGWON Vertical Roller Mill, Roller Press and

Hardness varies from 55 to 67 HRC and temperature application up to maximum 850 °C. Can be used for vertical mill body liner, classifier blade, cooler EP hot gas duct, liner for clinker crusher hammer casing, inlet

Hardfacing rebuilding LM 56.4 vertical mill roller YouTube

2018年1月8日LM 56.4 Vertical mill Roller hardfacing rebuilding. HH-806 flux cored welding wire for Buffer Layer, HH-810 for wear deposite. for more information pls conta...

mill/sbm hardfacing of vertical cement mill.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

id/hardfacing of vertical cement mill.md at main lqdid/id

Contribute to lqdid/id development by creating an account on GitHub.

Jual Hardfacing Vertical Roller Mill Harga Terbaru PT. Budi

Budi Mandiri Karunia Jual Hardfacing Vertical Roller Mill Harga Terbaru, TerlengkapTerpercaya. Dapatkan Produknya, Cek Sekarang Juga! Skip to content. Top Bar. Call: Email: budimandirikarunia@gmail Primary Menu. Home; About Us; Product and Service. Welding Machines Control;

China Vertical Roller Mill Hardfacing Manufacturers, Suppliers,

China Vertical Roller Mill Hardfacing Manufacturers, Suppliers, Factory Customized Vertical Roller Mill Hardfacing Price Leigong Vertical Roller Mill Hardfacing Name:LZ3071 φ1.6-2.8mm,HB200-250. C:≤0.5%, Cr:12.0-15.0%, Mn:13.0-16.0% LZ3071 is a austenite microstructure high Cr-Mn welding wires, offering wonderful toughness

hardfacing techniques in vrm cement mill Fonz

Vertical mill is widely used in cement mill, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other mineral production industries. Arcwel Hardfacing Die Steel Welding Cast Iron

Vertical Roller Mill Hardfacing Cladding Machine for sale

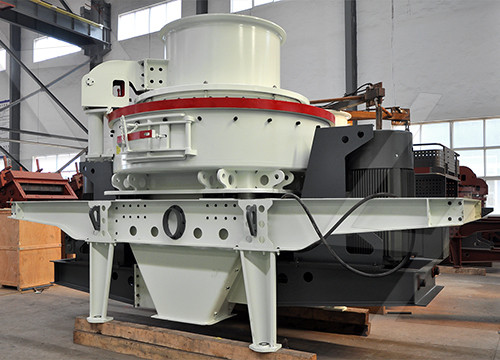

JH-350SL has the both function of automatic carbon arc gouging and hardfacing welding. It can control synchronous surfacing of roller press, vertical mill, continuous casting roller and coal mill roller. The machine is capable to achieve the welding job that including automatic circular welding, oscillation welding, linear welding, diamond

- 石头粉碎设备多少钱

- What Is Compressive Strength Of Concrete

- 雷蒙磨沈阳

- Jenis Bahan Shaft Jow Mining Mill

- 五台石料厂利润高吗

- 世邦破碎锤

- Electrical Wiring Diagram Concrete Batching Plant

- 辽宁省朝阳市哪里有卖刻石机

- 反击破以后石头形状是什么样的

- Grinding Machines And Their Prices In Assam

- 非煤矿矿山企业安全生产许可证样本

- Used Gold Mining Hoppers

- Sulphur Grinding Equipment

- Pe Stone Jaw Crushing Equipments

- 加工咸盐设备厂家