Ball Mill Grinding Process Static Control

Constrained model predictive control in ball mill grinding

2008年8月1日The schematic diagram of DMC applied in the ball mill grinding process. All the signals coming from the sensors of the grinding process are collected in a

Process Control of Ball Mill Based on MPC-DO Hindawi

2021年7月26日Furthermore, a compound control strategy for process control of the ball mill is proposed to describe the grinding process precisely where disturbances exist. It

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日Abstract The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic

Supervisory expert control for ball mill grinding circuits

2008年4月1日Fig. 4. Schematic diagram of supervisory expert control for grinding circuits. In the regulatory level, ball mill solid concentration variable-ratio control, sump

Process Control of Ball Mill Based on MPC-DO

2021年7月26日The grinding process of the ball mill is an essential operation in metallurgical concentration plants. Generally, the model of the process is established as

Intelligent optimal control system for ball mill grinding

2013年7月4日Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while

Grinding in Ball Mills: Modeling and Process Control Semantic

2012年6月1日An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented. Abstract The stone

Ball milling: a green technology for the preparation

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日DOI: 10.2478/cait-2012-0012 Corpus ID: ; Grinding in Ball Mills: Modeling and Process Control @inproceedings{Monov2012GrindingIB, title={Grinding

Constrained model predictive control in ball mill grinding process

2008年8月1日Moreover, static decoupling is often used which will degrade the control performance in real practice, while MPC scheme is much suitable for this case. 3. The run results show that the proposed DMC scheme is an effective way to control ball mill grinding process.

Constrained model predictive control in ball mill grinding process

2008年8月1日Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant. Grinding process represents almost half of the total operating costs associated with the mining operation, and the product particle size greatly influences the recovery rate of the valuable minerals and

Process Control of Ball Mill Based on MPC-DO ResearchGate

2021年7月26日The grinding process of the ball mill is an essential operation in metallurgical concentration plants. Generally, the model of the process is established as a multivariable system characterized

162 IEEE TRANSACTIONS ON CONTROL SYSTEMS

superscript Setpoint of the relevant control loop. When the grinding process operation starts, the fresh coarse ore from an ore bin is fed onto a conveyer belt by a vibratory feeder at a certain speed, and then conveyed continuously into the ball mill together with a certain amount of mill water. A

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

AUTOMATION ADVANCED CONTROL EXPERT (ACE)

BALL MILL ACE 5 CRUSHER ACE 6 SUCCESS STORY: COMPAÑÍA MINERA DOÑA INéS DE COLLAHUASI 7 PROCESS CONTROL HIERARCHY. 4 1 Here the unit operation is poorly controlled. It has a large in the SAG mill to promote optimum grinding. This stra-tegy has improved mill throughput by 5.9%, reduced feed

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the

Grinding Circuit Control Strategy MetallurgistMineral

2020年11月8日The ball mill load control system: The main control scheme is the ball mill load controller. Any additional capacity of the ball mill depending on the grind settings is sensed by the ball mill load controller and the feed rate is increased (if desired to bring the ball mill its capacity).

Modelling and Control of Ball Mill Grinding

2018年2月17日Experimental. A continuous grinding experiment is performed in a Denver 40 x 40 cm grate discharge ball mill. The mill feed (quartz in the range of 600-1700 um) is delivered by a PI-controlled belt conveyor accurate to ±1%. The water addition to the mill is automatically adjusted by a peristaltic pump to maintain a constant percentage of

Model based supervisory control of a ball mill grinding circuit

1999年6月1日Model based supervisory control of a ball mill grinding circuit @article{Radhakrishnan1999ModelBS, title={Model based supervisory control of a ball mill grinding circuit}, author={V. R. Radhakrishnan}, journal={Journal of Process Control}, year={1999}, volume={9}, pages={195-211} } V. Radhakrishnan; Published 1 June 1999;

Constrained model predictive control in ball mill grinding process

2008年8月1日A composite control scheme based on MPC-DO is put forward to realize the control of the three-input-three-output ball mill system and has good performance of tracking and anti-interference in process control ofThe ball mill. PDF Disturbance rejection of ball mill grinding circuits using DOB and MPC Jun Yang, Shihua Li, Xisong Chen, Qi Li

Modeling and Simulation of Whole Ball Mill Grinding Plant for

2014年1月17日This stone introduces the development and implementation of a ball mill grinding circuit simulator, NEUSimMill. Compared to the existing simulators in this field which focus on process flowsheeting, NEUSimMill is designed to be used for the test and verification of grinding process control system including advanced control system

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. CoolingHeating Mixer Mill MM 500 control

Coal grinding technology: a manual for process engineers.

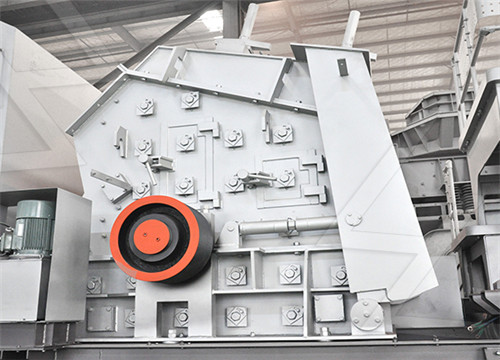

The hammer mill grinding system and the ball and race mill grinding system have been installed. Testing of various coal samples has been underway in the air swept ball mill grinding system. Modifications to the wet ball mill were delayed while an emergency repair of the sample preparation crusher was made.

Constrained model predictive control in ball mill grinding process

2008年8月1日Moreover, static decoupling is often used which will degrade the control performance in real practice, while MPC scheme is much suitable for this case. 3. The run results show that the proposed DMC scheme is an effective way to control ball mill grinding process.

Constrained model predictive control in ball mill grinding process

2008年8月1日Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant. Grinding process represents almost half of the total operating costs associated with the mining operation, and the product particle size greatly influences the recovery rate of the valuable minerals and

162 IEEE TRANSACTIONS ON CONTROL SYSTEMS

superscript Setpoint of the relevant control loop. When the grinding process operation starts, the fresh coarse ore from an ore bin is fed onto a conveyer belt by a vibratory feeder at a certain speed, and then conveyed continuously into the ball mill together with a certain amount of mill water. A

Process Control of Ball Mill Based on MPC-DO ResearchGate

2021年7月26日The grinding process of the ball mill is an essential operation in metallurgical concentration plants. Generally, the model of the process is established as a multivariable system characterized

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the

AUTOMATION ADVANCED CONTROL EXPERT (ACE)

BALL MILL ACE 5 CRUSHER ACE 6 SUCCESS STORY: COMPAÑÍA MINERA DOÑA INéS DE COLLAHUASI 7 PROCESS CONTROL HIERARCHY. 4 1 Here the unit operation is poorly controlled. It has a large in the SAG mill to promote optimum grinding. This stra-tegy has improved mill throughput by 5.9%, reduced feed

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日Ball Mills In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals.

Modelling and Control of Ball Mill Grinding

2018年2月17日Experimental. A continuous grinding experiment is performed in a Denver 40 x 40 cm grate discharge ball mill. The mill feed (quartz in the range of 600-1700 um) is delivered by a PI-controlled belt conveyor accurate to ±1%. The water addition to the mill is automatically adjusted by a peristaltic pump to maintain a constant percentage of

Model based supervisory control of a ball mill grinding circuit

1999年6月1日Model based supervisory control of a ball mill grinding circuit @article{Radhakrishnan1999ModelBS, title={Model based supervisory control of a ball mill grinding circuit}, author={V. R. Radhakrishnan}, journal={Journal of Process Control}, year={1999}, volume={9}, pages={195-211} } V. Radhakrishnan; Published 1 June 1999;

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日DOI: 10.2478/cait-2012-0012 Corpus ID: ; Grinding in Ball Mills: Modeling and Process Control @inproceedings{Monov2012GrindingIB, title={Grinding in Ball Mills: Modeling and Process Control}, author={Vladimir V. Monov and B. V. Sokolov and Stefan Stoenchev}, year={2012} }

Modeling and Simulation of Whole Ball Mill Grinding Plant for

2014年1月17日Compared to the existing simulators in this field which focus on process flowsheeting, NEUSimMill is designed to be used for the test and verification of grinding process control system including advanced control system such as integrated control.

Coal grinding technology: a manual for process engineers.

The hammer mill grinding system and the ball and race mill grinding system have been installed. Testing of various coal samples has been underway in the air swept ball mill grinding system. Modifications to the wet ball mill were delayed while an emergency repair of the sample preparation crusher was made.

constrained model predictive control in ball mill grinding process

Contribute to jidafang2022/en development by creating an account on GitHub.