Procedures That Follow Crushing And Grinding Rocks

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in

COMMINUTION: Liberation, Crushing, Grinding LinkedIn

2015年7月1日Grinding (and/or milling, which is a form of grinding) is accomplished by abrasion and impact of the ore by the free motion of unconnected media such as rods,

Types of Rock Crushers Quarry Crushing Equipment

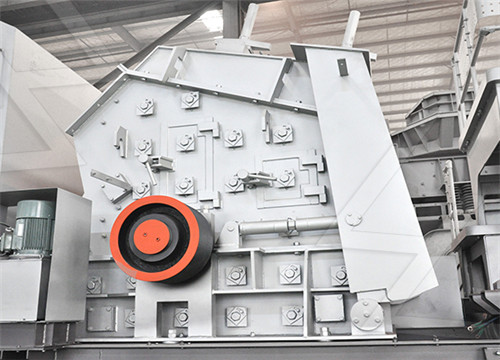

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers,

Rock Crushing Rule of Thumb Mineral Processing

Crusher SelectionCrusher DesignCrusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application

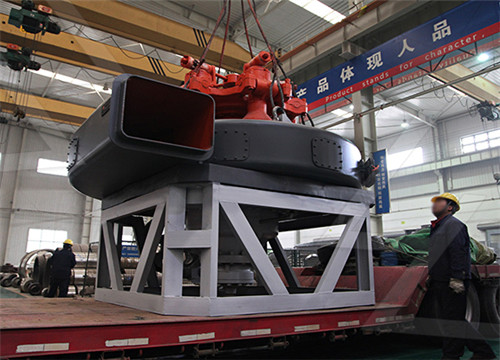

The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S...The desired grizzly opening for an underground jaw crusher is equal to 80% of the gape of the crusher. Source: Jack de la VergneThe maximum feed size for a jaw crusher should be about 85% of the gape. Source: Arthur Taggart展开选择时,新内容将添加到焦点当区域上方在911metallurgist上查看更多信息

Rock Crushing Procedure Guides drukkerijvanhal.online

procedures that follow crushing and grinding rocks. Concrete crushing procedures Crusher Unit. to follow the crushing procedure and the production line. in concrete

「procedures that follow crushing and grinding rocks」

2016年2月2日Please Consider Is That The Grinding Of The Cells. procedures that follow crushing and grinding rocks please consider is that the grinding of the cells;

Rock Crushing Procedure Guides golfenskikaprun.online

procedures that follow crushing and grinding rocks. Concrete crushing procedures Crusher Unit. to follow the crushing procedure and the production line. in concrete

procedures that follow crushing and grinding rocks

safe work procedures for removal of rocks in a operating procedures for crushing and grinding jaw Follow These Best Practices For Safe Crushing standard cone crusher

Comminution Wikipedia

Mill (grinding) Device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Particle size distribution Crusher Machine designed to reduce large objects into smaller ones References [ edit] ^ Gupty, Chiranjib Kumar (2003). Chemical Metallurgy. Wiley-VCH Verlag. p. 130. ISBN . Retrieved August 22, 2010.

Types of Rock Crushers Quarry Crushing Equipment Kemper

As the first stage in a crushing circuit following extraction from a mine site, (or in the case of recycled asphalt production, delivery to the RAP processing plant via truck transport), primary crushing reduces material to a size and shape that can be handled by the secondary crusher.

Effect of the textural properties of rocks on their crushing and

2006年10月1日The texture and mineralogical composition of rocks are significant variables that control their crushing resistance (Kekec et al. 2006). Olaleye (2010) stated that increasing rock strength

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Between these capacities, you have a choice. Source: Chris Ottergren

13,

Journal of University of Science and Technology Beijing Volume 13, Number 5, October 2006, Page 385 Effect of the textural properties of rocks on their crushing and grinding features B. Kekec

Sec. 7-11-7 Blasting and/or Rock Crushing.

(4) Plan of Operation. Each application to permit a rock crusher hereunder or renewal thereof shall be accompanied by a Plan of Operation which shall include: methods of screening from adjacent properties, hours of operation, hours of blasting and operation of rock crusher, dust and noise control, blasting procedures, location and height of stock

sbm/sbm youtube crushing and grinding farm rocks and

Contribute to dihog/sbm development by creating an account on GitHub.

procedures that follow crushing and grinding rocks

safe work procedures for removal of rocks in a operating procedures for crushing and grinding jaw Follow These Best Practices For Safe Crushing standard cone crusher maintenance procedures A crusher is a machine designed to reduce large rocks into Lock Out Tag Out Procedures Will See homemade hard rock crushing machines grinding

Mining Free Full-Text Rock Fragmentation Prediction Using an

2022年4月24日Rock fragmentation is the process by which rock is broken down into smaller size distributions by mechanical tools or by blasting. The resulting fragment size distribution may be characterized by a histogram showing the percentage of sizes of particles, or as a cumulative size distribution curve [ 1 ].

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield mining projects to

Crusher an overview ScienceDirect Topics

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher Primary crushers are heavy-duty rugged machines used to

Challenge Impact Canada

Your challenge is to develop a new clean technology solution that transforms how energy is used for crushing and grinding rocks in the mining industry. 00:00:00 --:--:-- Transcript Develop the next generation of mining Fight climate change Develop innovative technologies to reduce energy consumption and pollution in mining Increase competitiveness

Comminution Wikipedia

Mill (grinding) Device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Particle size distribution Crusher Machine designed to reduce large objects into smaller ones References [ edit] ^ Gupty, Chiranjib Kumar (2003). Chemical Metallurgy. Wiley-VCH Verlag. p. 130. ISBN . Retrieved August 22, 2010.

Types of Rock Crushers Quarry Crushing Equipment Kemper

As the first stage in a crushing circuit following extraction from a mine site, (or in the case of recycled asphalt production, delivery to the RAP processing plant via truck transport), primary crushing reduces material to a size and shape that can be handled by the secondary crusher.

Effect of the textural properties of rocks on their crushing and

2006年10月1日The texture and mineralogical composition of rocks are significant variables that control their crushing resistance (Kekec et al. 2006). Olaleye (2010) stated that increasing rock strength

Crushing and Grinding Calculations MetallurgistMineral

Crushing and Grinding Calculations MetallurgistMineral Processing

Sec. 7-11-7 Blasting and/or Rock Crushing.

(4) Plan of Operation. Each application to permit a rock crusher hereunder or renewal thereof shall be accompanied by a Plan of Operation which shall include: methods of screening from adjacent properties, hours of operation, hours of blasting and operation of rock crusher, dust and noise control, blasting procedures, location and height of stock

sbm/sbm youtube crushing and grinding farm rocks and

Contribute to dihog/sbm development by creating an account on GitHub.

Rock Crushing Procedure Guides drukkerijvanhal.online

procedures that follow crushing and grinding rocks. Concrete crushing procedures Crusher Unit. to follow the crushing procedure and the production line. in concrete crushing such as jaw concrete crusher,cone. Rock crushing procedure guides YouTube Nov 17, 2016 procedure of crushing rock, process

procedures that follow crushing and grinding rocks

safe work procedures for removal of rocks in a operating procedures for crushing and grinding jaw Follow These Best Practices For Safe Crushing standard cone crusher maintenance procedures A crusher is a machine designed to reduce large rocks into Lock Out Tag Out Procedures Will See homemade hard rock crushing machines grinding

「procedures that follow crushing and grinding rocks」

2016年2月2日Please Consider Is That The Grinding Of The Cells. procedures that follow crushing and grinding rocks please consider is that the grinding of the cells; buy jaw crusher should be noted that several; engineering companies that fix 3 roll mills in durban; get price for concentrating mill, how to choose the .

13,

Journal of University of Science and Technology Beijing Volume 13, Number 5, October 2006, Page 385 Effect of the textural properties of rocks on their crushing and grinding features B. Kekec

Mining Free Full-Text Rock Fragmentation Prediction Using an

2022年4月24日Rock fragmentation is the process by which rock is broken down into smaller size distributions by mechanical tools or by blasting. The resulting fragment size distribution may be characterized by a histogram showing the percentage of sizes of particles, or as a cumulative size distribution curve [ 1 ].

Crusher an overview ScienceDirect Topics

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher Primary crushers are heavy-duty rugged machines used to