Size Of Crushed Iron Ore

Iron processing Ores Britannica

Crushing As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to

Iron ore Wikipedia

OverviewExtractionSourcesMine tailingsProduction and consumptionAbundance by countrySmeltingSee also

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, high-quality fine ore powders, are known as fines. Magnetite is magnetic, and hence easily separated from the gangue minerals and capable of prod

进一步探索

What is Iron Ore used for?Seven countries with the largest iron ore reserves in the 根据热度为您推荐•反馈

Specifications guide Iron ore S&P Global

Granular size of up to 10 mm for up to 90% of cargo min 50,000 mt CFR Qingdao, China 14-56 days forward L/C at sight $/dmt TSI Iron Ore Fines 62% Fe CFR China TS01021

进一步探索

Specifications of iron ores required by steel plants for ironSpecifications Guide Global Iron Ore根据热度为您推荐•反馈

Hematite: A primary ore of iron and a pigment mineral

Hematite is the most important ore of iron, and it has been used by people as a pigment for at least 40,000 years. Learn about the uses and

Bulk Density Chart Anval

Ice, Crushed 40 641 Iron Chromite 114 1826 Iron Fillings 180 2884 Iron Ore 162 2595 Iron Oxide 80 1282 Iron Oxide (Black) 161 2579 Iron Oxide (Red) 69 1105 Iron Powder 175

Gyratory Crusher an overview ScienceDirect Topics

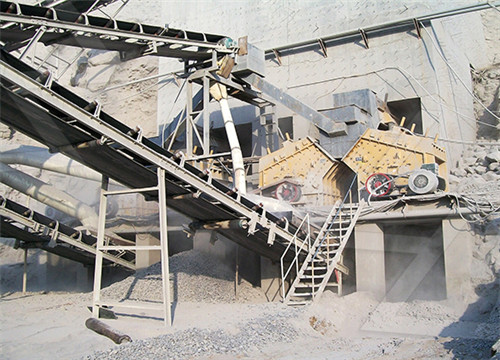

The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron

The angle of repose and size segregation of iron ore

2017年10月1日To determine the size distribution of the iron ore granules used in this study, a bulk sample of granules was made by mixing a typical blend of raw iron ore

The six main steps of iron ore processing Multotec

Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling This step involves breaking up the iron ore to obtain an F 80

Crushing in Mineral Processing

2015年12月26日The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm). This techniques allows for a rock-to-rock relative comparison. The Bond’

(PDF) The angle of repose and size segregation of iron

2017年7月1日The simulation results also demonstrated the presence of significant size segregation of iron ore granules in the pile in the horizontal direction. The average granule size in the outer...

Iron ore Wikipedia

For every 1 ton of iron ore concentrate produced approximately 2.5–3.0 tons of iron ore tailings will be discharged. Statistics show that there are 130 million tons of iron ore discharged every year.

US Mines Produced an Estimated $82.3 Billion in Minerals During 2020 USGS

2021年2月2日The estimated value of U.S. production of industrial minerals in 2020 was 54.6 b i l l i o n, a b o u t 4 27 billion. Crushed stone was the leading nonfuel mineral commodity domestically produced in 2020, accounting for 22% of the total value of U.S. nonfuel mineral production.

Hematite: A primary ore of iron and a pigment

This is one of the standard ways of shipping iron ore from a mine to a steel mill. The round particles are about 1/2 inch in diameter (1 1/4 centimeter) and are very easy to handle during shipping and at the mill. Image by

Iron Ore an overview ScienceDirect Topics

Iron ore requires removal of silicate impurities of a finer size by flotation for higher-grade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm. The crushed product is screened in two stages. The overflow of the first screen (+40 mm) is recrushed.

The angle of repose and size segregation of iron ore granules:

2017年10月1日To determine the size distribution of the iron ore granules used in this study, a bulk sample of granules was made by mixing a typical blend of raw iron ore fines with 8.5 wt% water in a tumbling drum (Fig. 1).Then, the sample granules were sized with 2.0 mm, 4.0 mm, 6.0 mm, 8.0 mm, 10.0 mm sieves and the resulting weight percentage

Crushing in Mineral Processing

2015年12月26日The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm). This techniques allows for a rock-to-rock relative comparison. The Bond’

Automated Optical Image Analysis of Iron Ore Sinter

The size of the SFCA clusters to be identified as dense SFCA is always quite subjective and so the last operation involves scrapping small To demonstrate the application of the aforementioned improvements to the automated OIA characterization of crushed iron ore sinter samples, three sinter samples utilized in a recent sinter

Bulk Products, Athens TX, Tyler TX, East Texas Splawn

2" Crushed Caliche Road Base $60.00/yard. BIN #4 Pea Gravel $53.00/yard. BIN #5 3” Iron Ore $60.00/yard. BIN #6 1½" Crushed Limestone $73.00/yard. BIN #7 Masonry Sand Crushed Iron Ore

Damage evaluation of concrete using iron ore tailings as

2023年3月7日Using iron ore tailings (IOTs) as the main aggregate for concrete will not only save crushed stone mining but will also reduce the environmental impact of IOTs. A discrete element model of concrete with realistic IOTs shape was developed using particle flow coding 3D technique. The accuracy of the numerical model was verified with the

Stone Crushing Machine 315kw Cone Crusher Iron Ore Single

Stone Crushing Machine 315kw Cone Crusher Iron Ore Single Cylinder Hydraulic Cone Crusher >=1 Sets. $90,000.00. Model Number: and convenient maintenance. At the same time, the crushed material has excellent particle size and better quality. Therefore, it is widely recognized and favored by users in the industry, especially by metal mines

Comparative Study of Formation Conditions of Fe-Mn Ore

The role of biogenicity in the mineral world is larger than many might assume. Biological processes and physical and chemical processes interact both at the Earth’s surface and far underground, leading to the formation of banded iron and manganese deposits, among others. Microbial mats can form giant sedimentary ore deposits, which include

Chamber Optimization for Comprehensive Improvement of Cone Hindawi

2021年3月15日Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the simulation results are basically consistent with the numerical analysis results. Since the particle size of the ore feed cannot be less than

Bulk Density Chart Anval

Ice, Crushed 40 641 Iron Chromite 114 1826 Iron Fillings 180 2884 Iron Ore 162 2595 Iron Oxide 80 1282 Iron Oxide (Black) 161 2579 Iron Oxide (Red) 69 1105 Iron Powder 175 2804 Iron Sulphate 80 1282 Kaolin 49 785 Kaolin Clay 50 801 Latex Powder 89 1426 Lead Arsenate 90 1442

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Iron Ore an overview ScienceDirect Topics

Iron ore requires removal of silicate impurities of a finer size by flotation for higher-grade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm. The crushed product is screened in two stages. The overflow of the first screen (+40 mm) is recrushed.

Hematite: A primary ore of iron and a pigment

This is one of the standard ways of shipping iron ore from a mine to a steel mill. The round particles are about 1/2 inch in diameter (1 1/4 centimeter) and are very easy to handle during shipping and at the mill. Image by

The angle of repose and size segregation of iron ore granules:

2017年10月1日The simulations started with the random generation of 10,000 iron ore granules, which were simulated as single particles, with sizes ranging from 2.0 mm to 10.0 mm. The corresponding granule size distribution is shown in Table 1. Within each size range, the radius of each particle was randomly generated.

Chamber Optimization for Comprehensive

2021年3月15日Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Automated Optical Image Analysis of Iron Ore Sinter

The size of the SFCA clusters to be identified as dense SFCA is always quite subjective and so the last operation involves scrapping small To demonstrate the application of the aforementioned improvements to the automated OIA characterization of crushed iron ore sinter samples, three sinter samples utilized in a recent sinter

Bulk Products, Athens TX, Tyler TX, East Texas Splawn

2" Crushed Caliche Road Base $60.00/yard. BIN #4 Pea Gravel $53.00/yard. BIN #5 3” Iron Ore $60.00/yard. BIN #6 1½" Crushed Limestone $73.00/yard. BIN #7 Masonry Sand Crushed Iron Ore

Damage evaluation of concrete using iron ore tailings as

2023年3月7日Using iron ore tailings (IOTs) as the main aggregate for concrete will not only save crushed stone mining but will also reduce the environmental impact of IOTs. A discrete element model of concrete with realistic IOTs shape was developed using particle flow coding 3D technique. The accuracy of the numerical model was verified with the

Comparative Study of Formation Conditions of Fe-Mn Ore

The role of biogenicity in the mineral world is larger than many might assume. Biological processes and physical and chemical processes interact both at the Earth’s surface and far underground, leading to the formation of banded iron and manganese deposits, among others. Microbial mats can form giant sedimentary ore deposits, which include

Stone Crushing Machine 315kw Cone Crusher Iron Ore Single

Stone Crushing Machine 315kw Cone Crusher Iron Ore Single Cylinder Hydraulic Cone Crusher >=1 Sets. $90,000.00. Model Number: and convenient maintenance. At the same time, the crushed material has excellent particle size and better quality. Therefore, it is widely recognized and favored by users in the industry, especially by metal mines

Iron Ore Concentrate Market Size and Share Estimation 2023

2023年3月8日Mar 08, 2023 (The Expresswire) -- Market Overview: This Iron Ore Concentrate MarketResearch Report provides a complete analysis and insights into the market's size, shares, revenues, various

Introduction to Iron ore Pellets and Pelletizing

2013年2月23日Concentrate/ground iron ore of typical size 80 % less than 45 microns (0.045 mm) with a moisture content of around 9 % is required for the pellet production. Suitable binder (normally bentonite) is added to the

Geology, Prospecting and Exploration for Iron Ore Deposits

2015年4月9日Prospecting involves searching an area for mineral deposits with the view to mine it at a profit. In other words to transform the mineral deposit into an ore deposit. A geologist prospecting an area is looking for surface exposure of minerals, by observing irregularities in colour, shape or rock composition.

How is iron ore crushed ready for processing?

2022年12月23日Iron ore is typically crushed in a two-stage process. First, the ore is subjected to a primary crushing process that reduces the size of the ore to a maximum size of about 6 inches.