Jaws Crusher Motor Installing

® C160™ jaw crusher Metso Outotec

Easy to install and transport ® C160™ jaw crusher for high-capacity primary crushing ® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day.

® C Series™ jaw crushers Metso Outotec

They can be installed within a few days, minimizing on-site engineering and fabrication. The jaw crushers can be upgraded with crusher automation that enable monitoring and

How to install a jaw crusher?

2023年1月30日Assemble the crusher: Follow the manufacturer's instructions to assemble the jaw crusher. Mount the crusher: Secure the crusher onto the base plate and align it

Installation of Jaw Crusher Skills and Notes JXSC Mine

The frame of the jaw crusher needs to install on the foundation before assembly crusher. Then install the other parts in sequence. 1. Frame

How to install the fixed jaw crusher machine Baichy

Before starting the fixed jaw crusher, the oil pump motor and cooling system should be started first. After 3-4 minutes, when the oil pressure and oil flow indicator are normal,

How to Properly Install and Use Jaw Crusher mpl

2022年3月22日Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell. Lifting

Jaw Rock Crusher BUILD Ep.5 YouTube

2021年8月20日Jaw Rock Crusher BUILD Ep.5 Donn DIY 878K subscribers Subscribe 12K 1.2M views 1 year ago #donndiy #rockcrusher #homemade Fabricating a jaw rock crusher from

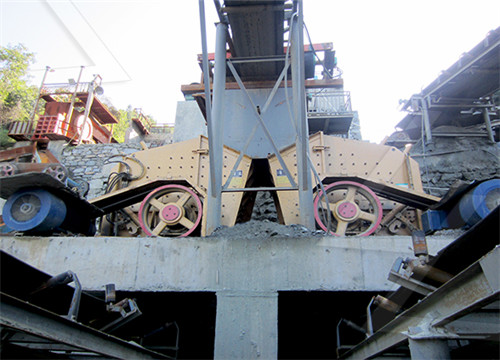

Jaw crusher: flywheel install YouTube

2014年1月8日XBM-one of the biggest mining machine manufacturers in Chinaxbm-machine

Jaws Crusher Motor Installing

The Orbis Wide Mouth Crusher is a dual action fine Jaw Crusher that will reduce samples from up to 70mm top size to as low as 95 passing 2mm in a single pass. The Wide

en/jaw s crusher motor installing.md at main lbsid/en

Contribute to lbsid/en development by creating an account on GitHub.

Jaw Crusher Series Technical Specification Mining and

Jaw Crusher Series Technical Specification Mining and Rock

® C Series™ jaw crushers Proven reliability and

reducing operating costs. With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved with an Crusher automation is easy to install and is provided as complete package including interface to all selected options such as crusher motor starter, hydraulic powerpack

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw crusher

Installation of Jaw Crusher Skills and Notes JXSC Mine

The frame of the jaw crusher needs to install on the foundation before assembly crusher. Then install the other parts in sequence. 1. Frame installation The installation of the crusher frame should be pad

Jaw Rock Crusher BUILD Ep.5 YouTube

2021年8月20日Jaw Rock Crusher BUILD Ep.5 Donn DIY 878K subscribers Subscribe 12K 1.2M views 1 year ago #donndiy #rockcrusher #homemade Fabricating a jaw rock crusher from

How to Properly Install and Use Jaw Crusher mpl

2022年3月22日Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell. Lifting the rod bolt, then install the bolts and tighten them. The bracket should be added when the oil leakage occurs due to poor fitting.

en/jaw s crusher motor installing.md at main lbsid/en

Contribute to lbsid/en development by creating an account on GitHub.

Jaws Crusher Motor Installing

The Orbis Wide Mouth Crusher is a dual action fine Jaw Crusher that will reduce samples from up to 70mm top size to as low as 95 passing 2mm in a single pass. The Wide Mouth Crusher has a 7.5kw motor and 400mm wide jaws adding both power and up to 25 faster processing times..

MBMMLLC: Jaw crusher maintenance and operation video

2015年4月1日We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap adjustment, belt

Jaw Crushers JW Series

• Electric motor • Mid-mount bolt-on support feet Standard Features • Hydraulic wedge jaw adjustment • Internally mounted hydraulics MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 hp

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary

New design jaw crusher/stone crusher machine with good price

Motor Type: AC Motor. Capacity(t/h): 1-220, 1-220. Place of Origin: Henan, China. Brand Name: Hongji. Jaw Crusher Application: High capacity, less costly and Easy to install. 4. The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of

Jaw Crushers Heavy Duty Finlay

The Finlay® J-1160 mobile jaw crusher is a primary crusher for aggregates production as well as concrete and asphalt recycling applications. The machine has hydrostatic drive which offers reversible operation for clearing blockages and demolition applications. It is designed to be easy to transport between sites and quick to set up and tear down.

Jaw Crusher Series Technical Specification Mining and

Jaw Crusher Series Technical Specification Mining and Rock

® C200™ jaw crusher Metso Outotec

EASY TO INSTALL AND TRANSPORT Even though ® C200™ jaw crusher is a large machine, its pinned and bolted frame design makes it simple to transport and install also in underground mines. The main

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic

MBMMLLC: Jaw crusher maintenance and operation video

2015年4月1日We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap adjustment, belt

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw crusher

Jaw Rock Crusher BUILD Ep.5 YouTube

2021年8月20日Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap steel.What is a jaw rock crusher -...

How to Properly Install and Use Jaw Crusher mpl

2022年3月22日Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell. Lifting the rod bolt, then install the bolts and tighten them. The bracket should be added when the oil leakage occurs due to poor fitting.

Jaws Crusher Motor Installing

The Orbis Wide Mouth Crusher is a dual action fine Jaw Crusher that will reduce samples from up to 70mm top size to as low as 95 passing 2mm in a single pass. The Wide Mouth Crusher has a 7.5kw motor and 400mm wide jaws adding both power and up to 25 faster processing times..

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary

New design jaw crusher/stone crusher machine with good price

Motor Type: AC Motor. Capacity(t/h): 1-220, 1-220. Place of Origin: Henan, China. Brand Name: Hongji. Jaw Crusher Application: High capacity, less costly and Easy to install. 4. The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of

Jaw Crushers JW Series

• Electric motor • Mid-mount bolt-on support feet Standard Features • Hydraulic wedge jaw adjustment • Internally mounted hydraulics MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 hp

How to install ore jaw crusher?

2023年1月30日Published Jan 30, 2023. + Follow. Installing a jaw crusher can vary depending on the model and manufacturer, but generally, the process can be broken down into a few key steps: Make sure the

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic Cylinder 8. Toggle Plate 9. Swing Jaw 10. Discharge 11. Fixed Jaw Jaw Crusher Parts G: Gape width, b: maximum feed size,

Scott Rocklabs BOYD Elite

The ROCKLABS BOYD Elite is the world’s first double-acting fine jaw crusher, employing jaws that can hold up to 5kg of sample and crush a 70mm sample to 2mm in a single pass. Enquire WATCH Motor power: 5.5kW, 3 phase: Maximum input lump size: 70mm: Product Size-2mm passing up to 90% (sample size dependant) Width x Height x Depth: