Nickel Ore Processing Vibrating Screnn

A Complete Solution for Nickel Ore Processing Fote Machinery

Process Flow of Copper-Nickel Sulfide OreProcess Flow of Nickel Oxide OreConclusionNickel oxide deposits are loose clay-like ore composed of iron, aluminum, silicon, and other hydrous oxides. Due to the oxidation of iron, the ore is red, so it is called laterite ore. The beneficiation process of laterite ore is mainly to prepare qualified ore or pulp for smelting.Given the different properties and smelting requirements of laterit...

Nickel Ore Beneficiation Plant Nickel Ore Processing

Nickel Ore Processing Equipment Star Trace Nickel Ore Processing uses the following equipments for the entire process: Hydrocyclone, Dewatering Screen, Magnetic Roll

进一步探索

Process flowsheet development for beneficiation of nickeProcessing routes for copper and nickel ores. Research根据热度为您推荐•反馈

Vibrating Screen Nickel Ore Processing Star Trace Pvt. Ltd.

Nickel Ore Processing Equipment Vibrating Screen Get Quote Instantly Vibrating Screen The type universal Vibro Screen is a new generation vibratory screening machine

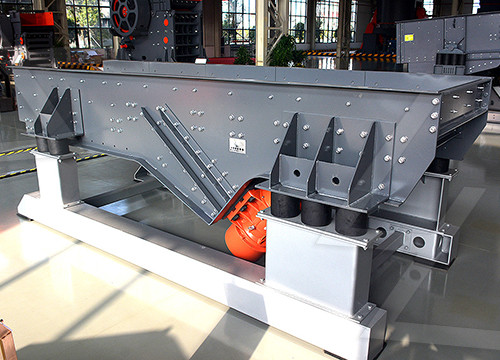

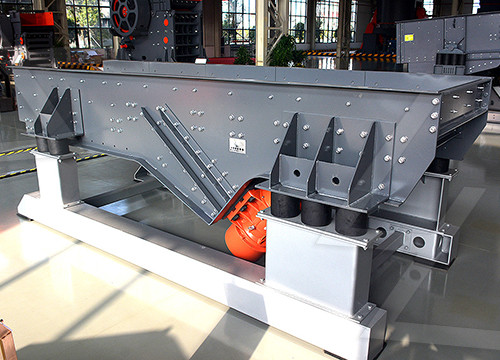

3-layer nickel ore beneficiation vibrating screen high capacity

The nickel ore should first be roughly broken by the jaw crusher, and then the circular vibrating screen is mainly used to screen the crushed nickel ore materials. The

Nickel Ore Mine Ore Vibrating Screen China Mine Machinery and

Nickel Ore Mine Ore Vibrating Screen, Find Details and Price about Mine Machinery Ore Vibrating Screen from Nickel Ore Mine Ore Vibrating Screen Shicheng Pioneers

Nickel Ore Mining Process,Processing Nickel Ores,Nickel

Nickel Ore Mining Process,Processing Nickel Ores,Nickel Process Serving-Beijing HOT Mining Tech Co Ltd Nickel is convalescing by extractive metallurgy. The majority sulfide ores have conservatively been

High Efficiency Vibro Separator Machine Nickel Ore Vibrating

High quality High Efficiency Vibro Separator Machine Nickel Ore Vibrating Sieve Screen from China, China's leading Nickel Ore Vibro Separator Machine product, with strict

Nickel Ore Beneficiation Plant Mineral Processing

Nickel ore processing usually needs to go through three processes: crushing screening- grinding- flotation separation- drying, and magnetic separation and gravity separation are

Iron Ore Beneficiation Mineral Processing

This vibrating screen is a 1 layer screen with a 5mm mesh size. 9-Over screen more than 5mm is back to double roll crusher for reprocessing. 10-Under screen less than 5mm are

Methods of Springs Failures Diagnostics in Ore Processing Vibrating Screens

2019年9月13日Methods of Springs Failures Diagnostics in Ore Processing Vibrating Screens. IOP Conference Series: Earth and Environmental Science,Volume 362,World Multidisciplinary Earth Sciences Symposium (WMESS 2019) 9–13 September 2019, Prague, Czech Republic Citation Pavlo Krot and Radoslaw Zimroz 2019 IOP Conf. Ser.: Earth

(PDF) Dynamic Modeling of a Vibrating Screen

2018年12月4日Vibrating screens are critical machines used for size classification in mineral processing. eir proper operation, including accurate vibration movement and slope angle, can provide the benefits of

Development and Verification of the Diagnostic Model of the Sieving Screen

2020年6月18日The considered vibrating screen is investigated on the 6-DOF (degree-of-freedom) dynamical model to reflect all linear and rotational components of spatial motion. P. Krot and R. Zimroz, “Methods of springs failures diagnostics in ore processing vibrating screens,” IOP Conference Series: Earth and Environmental Science, vol. 362

Screening, Separation and Vibration Mining Technology

Screening, Separation and Vibration Equipment for the Mining Industry Screening, classifying and separation are integral to ore processing, metals and minerals extraction, and controlling the final product quality in any mining and processing operation.

Enhanced methods for nickel recovery from low-grade

2017年9月6日Recovery of Nickel and Processing of Magmatic Sulfide Ores. The processing of magmatic sulfide ores differs from laterites: sulfide ores are crushed in multiple steps to separate the ore minerals from the

Methods of Springs Failures Diagnostics in Ore

2019年11月15日There are reports of this approach being applied for circular vibrating screens [38,39], linear vibrating screens [40][41][42], an elliptical vibrating screen [43] and banana screens [44,45].

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Nickel processing Extraction and refining Britannica

The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used. The major differences in equipment are the use of higher-temperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel production. The specific

3-layer nickel ore beneficiation vibrating screen high capacity

The nickel ore should first be roughly broken by the jaw crusher, and then the circular vibrating screen is mainly used to screen the crushed nickel ore materials. The qualified materials can be processed in the next step, and the unqualified ones can be returned to the previous step to continue crushing.

Nickel Ore Beneficiation Plant Mineral Processing

Nickel ore processing usually needs to go through three processes: crushing screening- grinding- flotation separation- drying, and magnetic separation and gravity separation are usually auxiliary beneficiation methods. 1. Crushing and screening: The feeder sends the mined raw ore to the jaw crusher for coarse crushing.

Slurry Pumps Nickel Ore Processing Star Trace Pvt. Ltd.

STAR TRACE is one of the most well recognized manufacturers of heavy duty, medium duty slurry and process pumps, vertical slurry pumps, ash slurry pumps, process pumps in India today. Our company manufacturers advanced slurry pumps and process pumps. Our pump handle tougher abrasive solids and slurry found in mining, steel and glass industries.

Vibrating Screen, Vibratory Screener, Mining Vibrating Screen

Vibrating screen is a common vibrating equipment used in the mineral processing. There are many types of screening equipment in the vibrating screen machine market, such as linear vibrating screen, circular vibrating screen. Matters Needing Attention in the Use of Vibrating Screen

High-frequency vibrating screens Wikipedia

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an

Nickel Ore Processing: Methods And Equipment Investment

2022年10月10日The important mineral sources of nickel are nickel sulfide ore and nickel oxide ore. And they require different processing methods. Equipment for copper-nickel sulfide ore, you need the following machines: Use a jaw crusher for primary crushing. Use a cone crusher for fine crushing. Use a vibrating feeder to screen out the products whose

Methods of Springs Failures Diagnostics in Ore Processing Vibrating Screens

2019年9月13日Large-scale vibrating screens are widely used in minerals processing industry. One of main components in any vibrating screen is a set of springs supporting the main body of machine with sieving material inside. These springs are subjected to cyclic loading and fatigue.

(PDF) Dynamic Modeling of a Vibrating Screen

2018年12月4日Vibrating screens are critical machines used for size classification in mineral processing. eir proper operation, including accurate vibration movement and slope angle, can provide the benefits of

Development and Verification of the Diagnostic Model of the Sieving Screen

2020年6月18日The considered vibrating screen is investigated on the 6-DOF (degree-of-freedom) dynamical model to reflect all linear and rotational components of spatial motion. P. Krot and R. Zimroz, “Methods of springs failures diagnostics in ore processing vibrating screens,” IOP Conference Series: Earth and Environmental Science, vol. 362

Enhanced methods for nickel recovery from low-grade

2017年9月6日Recovery of Nickel and Processing of Magmatic Sulfide Ores. The processing of magmatic sulfide ores differs from laterites: sulfide ores are crushed in multiple steps to separate the ore minerals from the

Nickel processing Extraction and refining Britannica

The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used. The major differences in equipment are the use of higher-temperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel production. The specific

Vibrating Screen Working Principle Mineral

2015年7月26日A vibrating mechanism attached to the middle of the screen imparts rapid vibrations of small amplitude to its surface, making the ore, which enters at the top, pass down it in an even mobile stream. The

Methods of Springs Failures Diagnostics in Ore

2019年11月15日There are reports of this approach being applied for circular vibrating screens [38,39], linear vibrating screens [40][41][42], an elliptical vibrating screen [43] and banana screens [44,45].

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Nickel Smelting and Refining International Finance

processing steps used for the two types of ores. Lateritic Ore Processing Lateritic ores have a high percentage of free and combined moisture, which must be removed. Drying removes free moisture; chemically bound water is removed by a reduction furnace, which also reduces the nickel oxide. Lateritic ores have

Slurry Pumps Nickel Ore Processing Star Trace Pvt. Ltd.

STAR TRACE is one of the most well recognized manufacturers of heavy duty, medium duty slurry and process pumps, vertical slurry pumps, ash slurry pumps, process pumps in India today. Our company manufacturers advanced slurry pumps and process pumps. Our pump handle tougher abrasive solids and slurry found in mining, steel and glass industries.

High-frequency vibrating screens Wikipedia

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an

Nickel Ore Processing: Methods And Equipment Investment

2022年10月10日The important mineral sources of nickel are nickel sulfide ore and nickel oxide ore. And they require different processing methods. Equipment for copper-nickel sulfide ore, you need the following machines: Use a jaw crusher for primary crushing. Use a cone crusher for fine crushing. Use a vibrating feeder to screen out the products whose

YA circular vibrating screen Yantai Jinpeng Mining equipment, ore

This series vibrating screen with simple structure, and easy to maintenance, reliable to operation, and screen efficiency high. It can desliming, dehydration and removing medium operation for medium-grained material for mining, coal, electricity, construction and chemical materials. And installation of rubber screen is preferred for grading cokes material.It is a

Vibrating Screen JXSC Mineral

A vibrating screen is a kind of mine classification machine for ore, mine, sand, gravel, coal, slurry, etc. which consists of a screen and a vibrator. Generally below 50 mesh for the coarse screen, 80 mesh for the fine screen. The vibrator is an eccentric wheel that rotates under the drive of the motor, making the sieve frame vibrate.

- 超细微粉磨粉机配件

- 高效粗磨机粗粉磨粉机

- Energy Efficient Garnet Sand Dryer Machine For Industrial Drying Use

- Stone Milling Used

- Basalt Impact Crusher With Iso For Gold Iron Ore Stone Crushing

- 性价比高的冼砂机

- HRM3700立磨滚套维修

- 特雷克斯制砂机直径700

- 激振筛

- 缅甸铝矿山

- 做石磨最好的材质

- 上海打砂机维修

- 挖掘机电脑主板图片

- 分为粗碎和细碎锤式破碎机

- The Long Service Spare Parts In Roll Crusher