Crusher And Grinder For Rocks How Does Produce Iron Lls And Crush

Types of Rock Crushers Quarry Crushing Equipment Kemper

Here at Kemper Equipment, we offer the best performing crushing equipment that will work hard to make any finished products you plan to

Rock Crusher MachinesPulverizers Williams Crusher

A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of

进一步探索

Crushing Equipment For Sale GovPlanetSmall Jaw Crusher For Sale Low Cost Of Mini Jaw Crusher根据热度为您推荐•反馈

Industrial Solutions Gyratory crushers ThyssenKrupp

which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed

Crushing in Mineral Processing

2015年12月26日As gravity pulls the rock down from the top of the crushing chamber (feed) to the discharge (close-side-setting), all rocks

All crusher types for your reduction needs Metso Outotec

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a

How to Build a Rock Crusher Home Guides SF Gate

2017年7月21日6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and

DIY Impact Mill/Rock Crusher Crush Anything (Gold Ore

2015年10月12日I built an impact mill that will crush a 4" rock into powder in under 1 second. This rock crusher is also known as a chain or a flail mill. I also run some aluminum cans and a circuit

Crushing Rocks with a Portable Rock Crusher. Portable

2021年7月13日Using a small Portable Rock Crusher. Portable Grinder. Looking for a gold Deposits. Arizona Desert.Help locate Gold Bearing Gravels. How to Read the Area

TECHTONGDA Jaw Crusher Rock Crush Machine Electric

2022年3月2日【Application】This machine is applicable to medium and fine crushed materials. Suitable for crushing materials such as calcite, talcum, cobblestone, kaolin,

Crusher an overview ScienceDirect Topics

The hammers, bars, and discs are made of manganese steel or cast iron containing chromium carbide. The hammers repeatedly strike the material to be crushed against a rugged solid surface of the crushing chamber breaking the particles to uniform size.

Hammer Mill CrusherGrinder Mineral ProcessingMetallurgy

2016年2月25日Hammer Mill CrusherGrinder is the best known and by far the most widely used crushing device employing the impact of breaking and grinding stone.

Crushing Plant FlowsheetDesign-Layout Mineral Processing

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Industrial Solutions Gyratory crushers ThyssenKrupp

which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush ing chamber below. Jaw gyratory crushers can handle much bigger chunks of

All crusher types for your reduction needs Metso Outotec

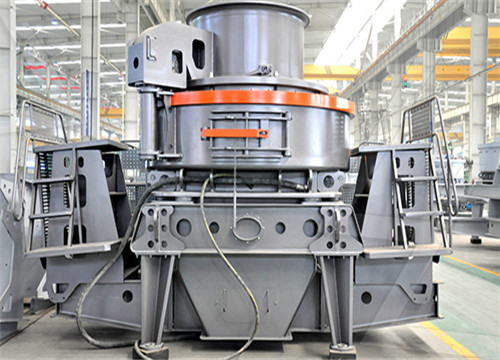

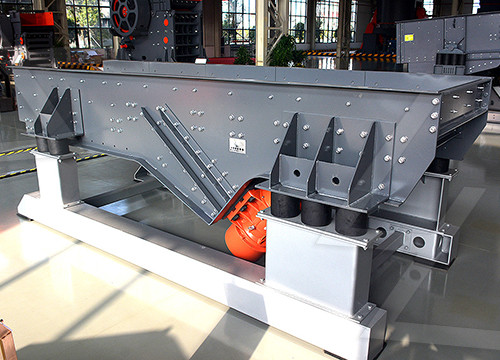

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need.

Cone Crusher an overview ScienceDirect Topics

The concrete C&D waste recycling process of “impact crusher + cone crusher + hoop-roller grinder” is also capable of handling brick waste. In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factor.

AggregateRock Crushing Equipment Stedman Machine

RockAggregate Crushing Equipment. Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for the construction of roads, buildings, and bridges. Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, , caulking, and glass.

How to Build a Rock Crusher Home Guides SF Gate

2017年7月21日6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and laying the clamp on the top

Crushing Rocks with a Portable Rock Crusher. Portable Grinder.

2021年7月13日Using a small Portable Rock Crusher. Portable Grinder. Looking for a gold Deposits. Arizona Desert.Help locate Gold Bearing Gravels. How to Read the Area for...

EIE Instruments Jaw crusher To crush Rock, Stone, Coal, Iron

2019年9月19日EIE MAKE jaw crusher is used to crush the coal, rock, stone, iron oar and many other substances in small size. This is extensively use in the laboratory to check the quality of the...

The Complete Guide to Crushed Stone and Gravel gra-rock

2019年11月11日Instead of being shaped or formed naturally, such as in a riverbed or canyon, crushed stone is produced with man-made machinery and processes. So what does this stone-crushing process look like? It begins with using a rock crusher in a place that has plenty of large rocks, such as a quarry.

Jaw Crushers McLanahan

A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom.

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatment.

Crusher Aggregate Equipment For Sale MachineryTrader

2 之Crusher Aggregate Equipment Price: USD $650,000 Get Financing* Machine Location: Forest Park, Georgia 30297 Hours: 945 Serial Number: K Condition: Used Compare TractorEquipment Company Birmingham, Alabama 35202 Phone: (205) 708-7059 Email Seller Video Chat

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield mining projects to

Crusher an overview ScienceDirect Topics

The hammers, bars, and discs are made of manganese steel or cast iron containing chromium carbide. The hammers repeatedly strike the material to be crushed against a rugged solid surface of the crushing chamber breaking the particles to uniform size.

Crushing Plant FlowsheetDesign-Layout Mineral Processing

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Industrial Solutions Gyratory crushers ThyssenKrupp

which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush ing chamber below. Jaw gyratory crushers can handle much bigger chunks of

Crushing in Mineral Processing

2015年12月26日As gravity pulls the rock down from the top of the crushing chamber (feed) to the discharge (close-side-setting), all rocks undergo multiple impacts causing them to get crushed. After TNT explosives, crusher are the most effective or efficiency rock size reduction hammer the mineral processing industry has.

AggregateRock Crushing Equipment Stedman Machine

RockAggregate Crushing Equipment. Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for the construction of roads, buildings, and bridges. Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, , caulking, and glass.

Cone Crusher an overview ScienceDirect Topics

The concrete C&D waste recycling process of “impact crusher + cone crusher + hoop-roller grinder” is also capable of handling brick waste. In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factor.

The Complete Guide to Crushed Stone and Gravel gra-rock

2019年11月11日Instead of being shaped or formed naturally, such as in a riverbed or canyon, crushed stone is produced with man-made machinery and processes. So what does this stone-crushing process look like? It begins with using a rock crusher in a place that has plenty of large rocks, such as a quarry.

How to Build a Rock Crusher Home Guides SF Gate

2017年7月21日6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and laying the clamp on the top

Crushing Rocks with a Portable Rock Crusher. Portable Grinder.

2021年7月13日Using a small Portable Rock Crusher. Portable Grinder. Looking for a gold Deposits. Arizona Desert.Help locate Gold Bearing Gravels. How to Read the Area for...

EIE Instruments Jaw crusher To crush Rock, Stone, Coal, Iron

EIE MAKE jaw crusher is used to crush the coal, rock, stone, iron oar and many other substances in small size. This is extensively use in the laboratory to check the quality of the...

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatment.

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic Cylinder 8. Toggle Plate 9. Swing Jaw 10. Discharge 11. Fixed Jaw Jaw Crusher Parts G: Gape width, b: maximum feed size,

Mobile crushers and screens — SRP

mobile crushers and screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects. Email us Request a quote.